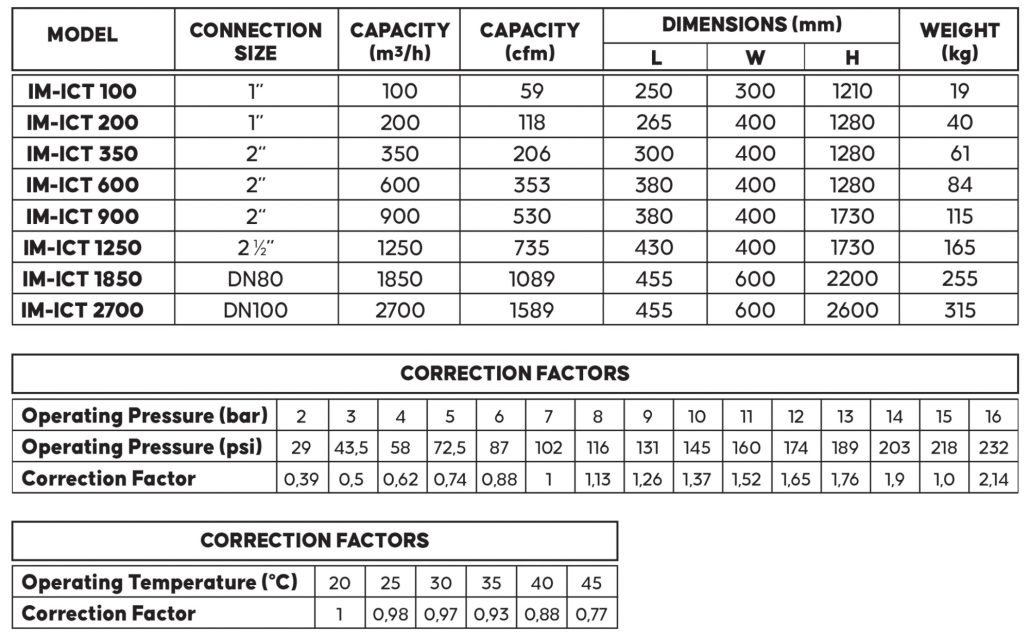

IM-ICT SERIES ACTIVATED CARBON TOWERS

Oil vapour adsorption: specific elimination of the second largest vapour phase in compressed air

IM-ICT Series Activated Carbon Towers reduce the oil vapour content of the compressed air to low residual levels. Oil vapour is the second largest vapour phase in compressed air and, like moisture, is highly likely to condense – in the case of oil vapour in condenses to form liquid oil.

High grade removal of oil vapour using an activated carbon tower reliably prevents condensation processes during the cooling of compressed air and thus the formation of liquid oil. In addition, activated carbon towers remove a variety of other hydrocarbons, odours and flavours.

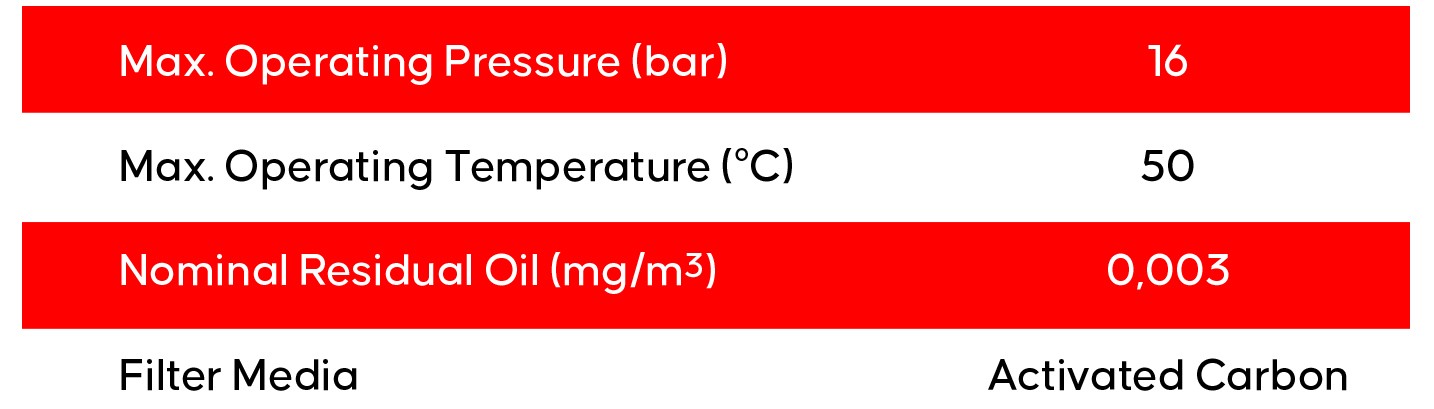

IM-ICT Series Activated Carbon Towers consist of welded and coated steel vessels, which are pressure-rated up to 16 barg. They are operated with activated carbon filling, consisting of 100% pure activated carbon. Stainless steel flow distributors at the inlet & outlet ensure uniform flow and reduced abrasion of the activated carbon.

IM-ICT Series Activated Carbon Towers are fitted with an oil indicator and vessel pressure gauge as standard. The oil indicator’s control point is approximately 20% before the activated carbon filling needs to be replaced in order to ensure sufficient life time reserve until the activated carbon is replaced.

ADVANTAGES:

- Easy installation

- Optimal adsorption of oil vapour (hydrocarbons)

- Optimized flow distribution

- Low pressure loss

- Residual oil content up to 0,003 mg/m3

- Oil indicator for checking the saturation level

- 10.000 hours of average activated carbon service life

- Low dust level at outlet through stainless steel flow distributor

- Maximum operational reliability

APPLICATIONS:

- Food-Beverage

- Medical

- Chemistry

- Pharmaceutical

- Process

- Metal Industry

- Air Treatment

- Electronics

- Gas Generator Plants

- Petrochemical

Super fine coalescing filter is required upstream ICT and 1mic. dust filter is recommended downstream to intercept activated carbon dust.