Adsorption dryers are used in environments where a specified pressure dew point from -20°C to -70°C has to be assured stably and securely. The IM-WHD series dryers are offered in two versions. As a compact aluminium series for volume flows up to 110 m3/h and with welded vessels for volume flows up to 3050 m3/h as part of the standard series. Higher volume flows are available upon request. Common to both series is consistently high quality compressed air. OPTIMAL OPERATIONAL RELIABILITY Using first-class materials, Ideal Makina produces heatless adsorption dryers that distinguish themselves through long service life and exceptional industrial equipment quality. The use of quality desiccants in combination with intelligent controls assures consistent compressed air and compressed gas quality, and stable pressure dew points (from -20°C to -70°C). Non-electrical change-over valves assure reliable and risk-free operation. Standardized high quality brand name blow-off valves extend the operating life, minimize service times and simplify maintenance significantly.

OPTIMAL COST EFFECTIVENESS DURING OPERATION & IN PRICE

The cost effective operation and functionality supplements the exceptional price-performance ratio. The intelligent ten minute ideal cycle (control cycle for adsorption, regeneration and pressure build-up) requires less regeneration energy than dryers with shorter cycles and saves adsorbents due to the lower number of alternating loads. The compressor synchronizing circuit that is integrated in the Control Panel as standard saves additional regeneration energy because the Control Unit runs only when the compressor is also running. Consequently no regeneration air escapes during standby times. In variable cycle with dew-point dependent control, a dew point sensor detects the pressure dew-point at the outlet of the adsorption dryer and extends the adsorption time according to the actual inlet conditions. The extended adsorption time results in energy saving phases, in ehivh no regeneration energy is required. In this way, energy savings up to 90% can be achieved.

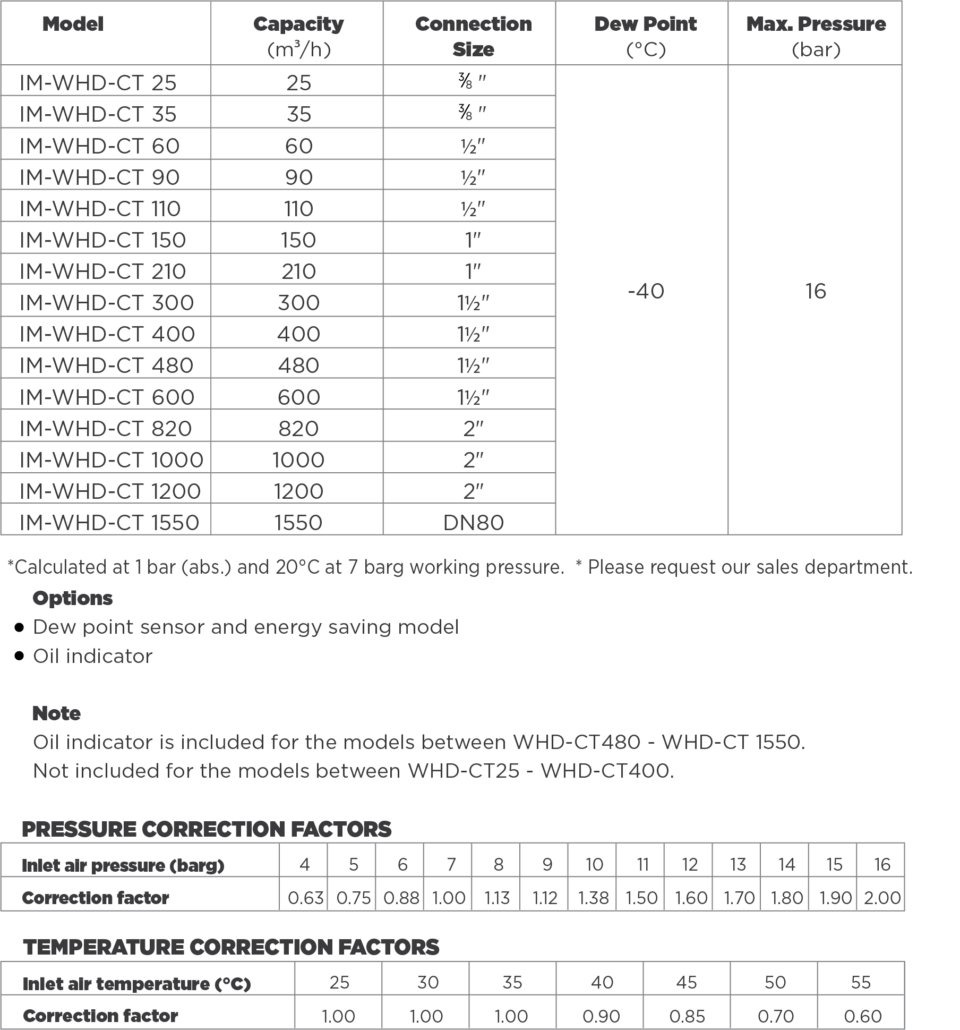

IM-WHD-CT SERIES OIL-FREE DESSICANT DRYER UP TO 1550 m3/h

Efficient and economical compressed air drying resulting from many features of the IM WHD series

Adsorption dryers are used in environments where a specified pressure dew point from -20°C to -70°C has to be assured stably and securely. The IM-WHD-CT series dryers are offered in two versions. As a compact aluminium series for volume flows up to 110 m3/h and with welded vessels for volume flows up to 1550 m3/h as part of the standard series. Higher volume flows are available upon request. Common to both series is consistently high quality compressed air. OPTIMAL OPERATIONAL RELIABILITY Using first-class materials, Ideal Makina produces heatless adsorption dryers that distinguish themselves through long service life and exceptional industrial equipment quality. The use of quality desiccants in combination with intelligent controls assures consistent compressed air and compressed gas quality, and stable pressure dew points (from -20°C to -70°C). Non-electrical change-over valves assure reliable and risk-free operation. Standardized high quality brand name blow-off valves extend the operating life, minimize service times and simplify maintenance significantly.

STABLE AND SAFE ACHIEVEMENT OF THE PRESSURE DEW POINT IS GUARANTEED

STABLE AND SAFE ACHIEVEMENT OF THE PRESSURE DEW POINT IS GUARANTEED

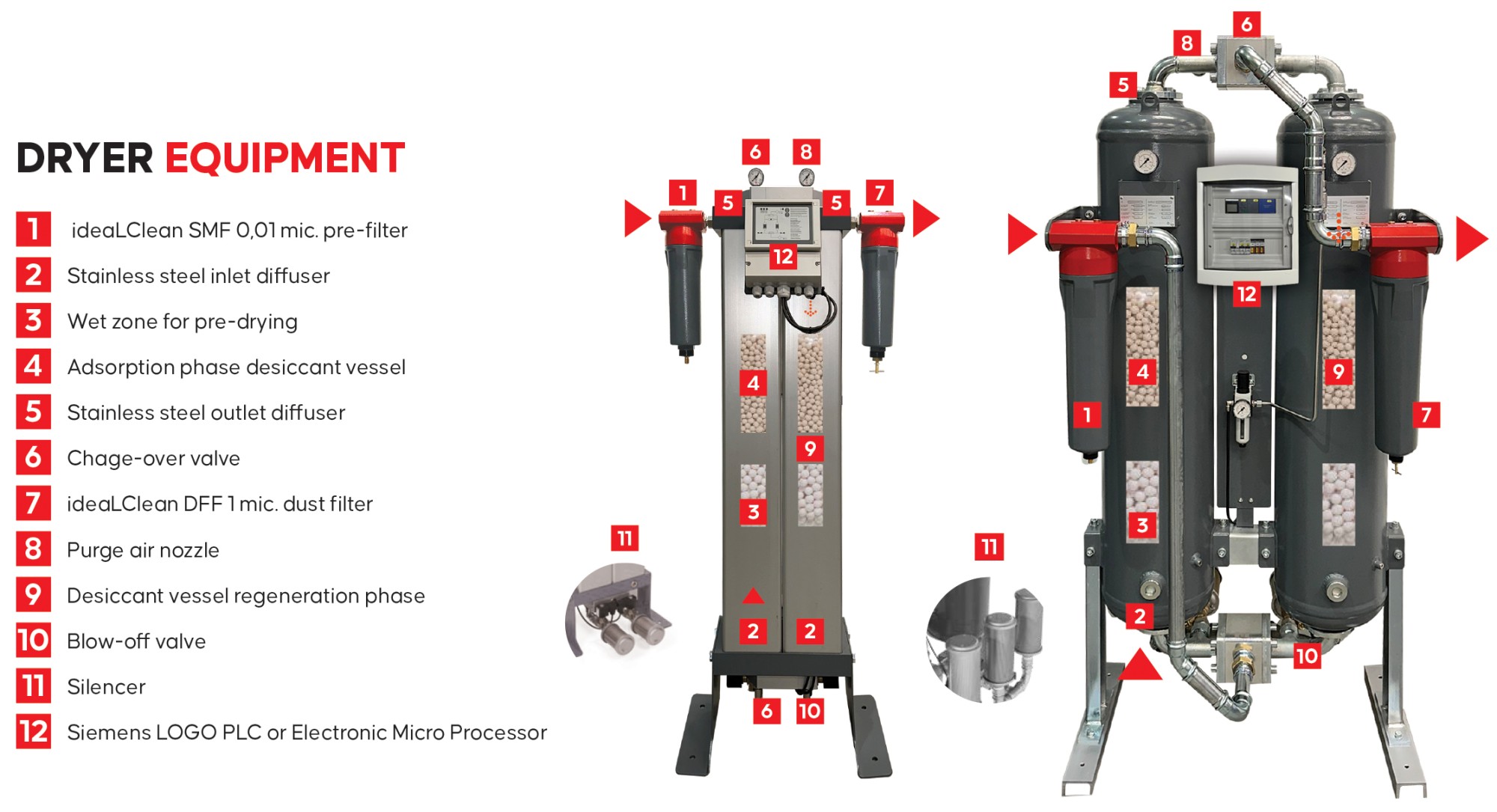

Prefiltration

In the flow-optimized ideaLClean SMF 0,01 mic. pre-filter, solid and liquid components are already simply separated from the saturated compressed air. Compressor condensate is reliably discharged via the electronic, level-controlled condensate drain (optional) without pressure losses.

Adsorption

The pre-cleaned compressed air is distributed through the flow distributor from the lower end of the adsorption vessel via the desiccant bed for predrying in the so-called, wet zone“. Then the actual adsorption takes place: by adsorption of water molecules on the large inner surface of the desiccant.

Postfiltration

The strongly dried compressed air flows through the entire desiccant bed at the upper end of the adsorption vessel via flow optimizer and a shuttle valve into the ideaLClean DFF for the final dust filtration. Now the high-purity compressed air is available.

Regeneration / Desorption

Parallel to adsorption in the first adsorption vessel the desiccant is regenerated in the second vessel. For this purpose, a small partial flow of the already dried compressed air from adsorption vessel one is passed through a rinsing air nozzle in countercurrent through the desiccant from vessel two. By using the physical effect of pressure relief at atmospheric pressure, the regeneration rinsing air dries the moisturized desiccant particularly effectively. The moisture is released into the atmosphere via the blowout valve and silencer.

Switching

When regeneration is complete, the pressure build-up begins in the vessel. Once the operating pressure has been reached, the system switches from the adsorbing container to the regenerated container. Now the freshly regenerated vessel starts adsorption, while the other vessel starts its regeneration cycle.

STABLE AND SAFE ACHIEVEMENT OF THE

STABLE AND SAFE ACHIEVEMENT OF THE