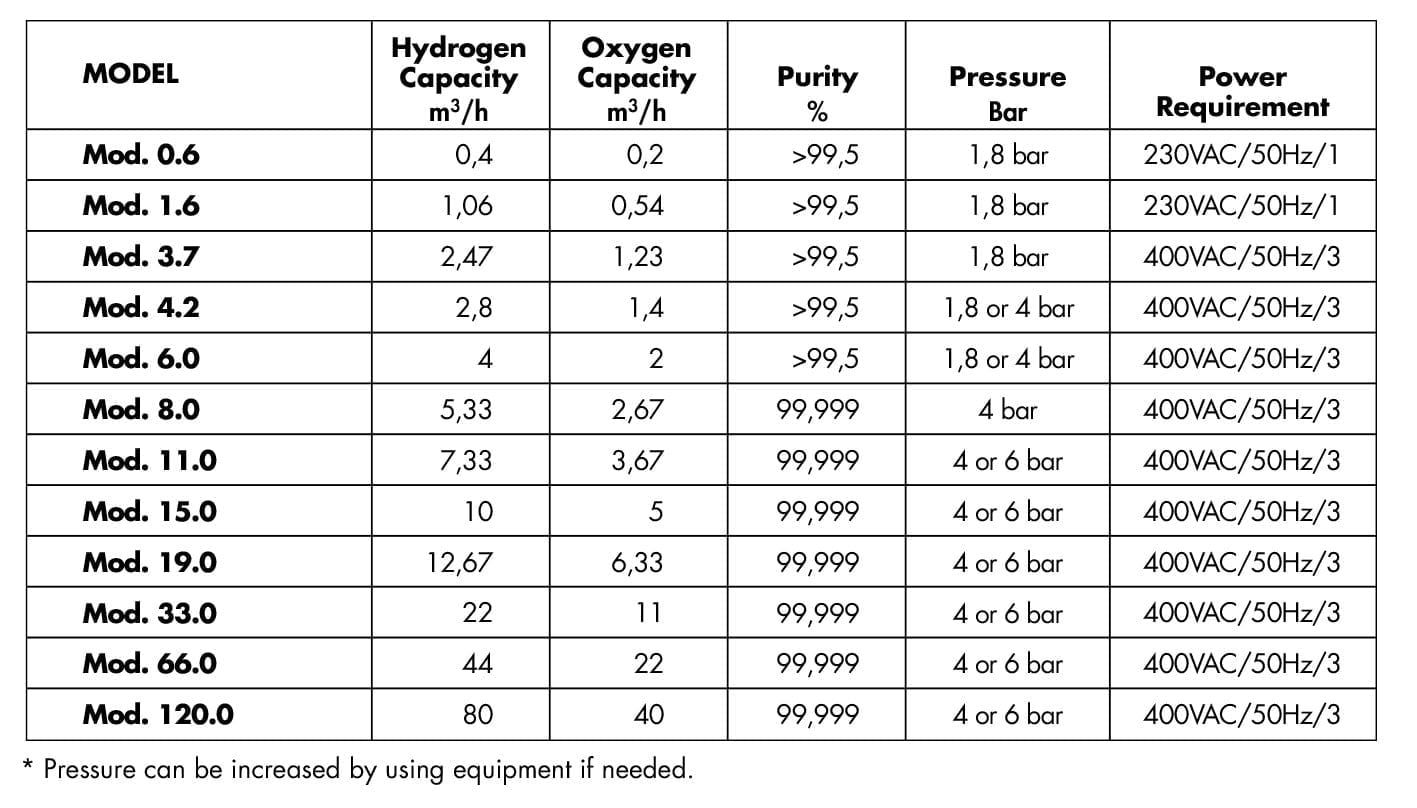

It is based on the process of producing hydrogen gas by seperating demineralized water at the anode and cathode pole in the electrolysis cell with the help of various catalysts. In the electrolysis method, 1 unit of oxygen gas is also produced for every 2 units of hydrogen gas. It consists of 4 main parts: Transformer, control panel, generator and hydrogen purification unit. Demineralized water, nitrogen gas and cooling water are the requirements for a functional system operation. It is suitable for 0-100 m3/h. capacity range and can be increased up to 300 bar pressure. Compared with the hydrogen cylinder purchasings costs, up to %90 savings on unit gas is provided and the system pay itself in a very short time.

It is based on the process of producing hydrogen gas by seperating demineralized water at the anode and cathode pole in the electrolysis cell with the help of various catalysts. In the electrolysis method, 1 unit of oxygen gas is also produced for every 2 units of hydrogen gas. It consists of 4 main parts: Transformer, control panel, generator and hydrogen purification unit. Demineralized water, nitrogen gas and cooling water are the requirements for a functional system operation. It is suitable for 0-100 m3/h. capacity range and can be increased up to 300 bar pressure. Compared with the hydrogen cylinder purchasings costs, up to %90 savings on unit gas is provided and the system pay itself in a very short time.

In the electrolysis method, the system consists of 4 main units: Transformer, electrical control panel, hydrogen generator and hydrogen purification unit. It is possible to reach %99,999 hydrogen purity by using nitrogen purification unit with patented Italian technology. Instant quality analysis can be made through the special purity and humidity sensor palced at the hydrogen outlet.