Performance Of Refrigeration Dryers AMD:

Compressed air contains contaminants such as water, oil and particulates which must be removed or reduced to the acceptable level based on specific application requirements. Standard ISO 8573-1 specifies air purity/quality classes for these contaminants. Humidity (water vapour content) is expressed in the terms of Pressure Dew Point (PDP) where Dew point is the temperature at which air is 100% saturated with moisture. When the temperature of the air reduces to or below the dew point, condensation will occur. Reduction of water content down to pressure dew point +3°C is usually achieved with refrigerant dryers.

Refrigeration compressed air dryers AMD have been designed to effectively separate water from the compressed air thus lower pressure dew point all the way down to +3°C.

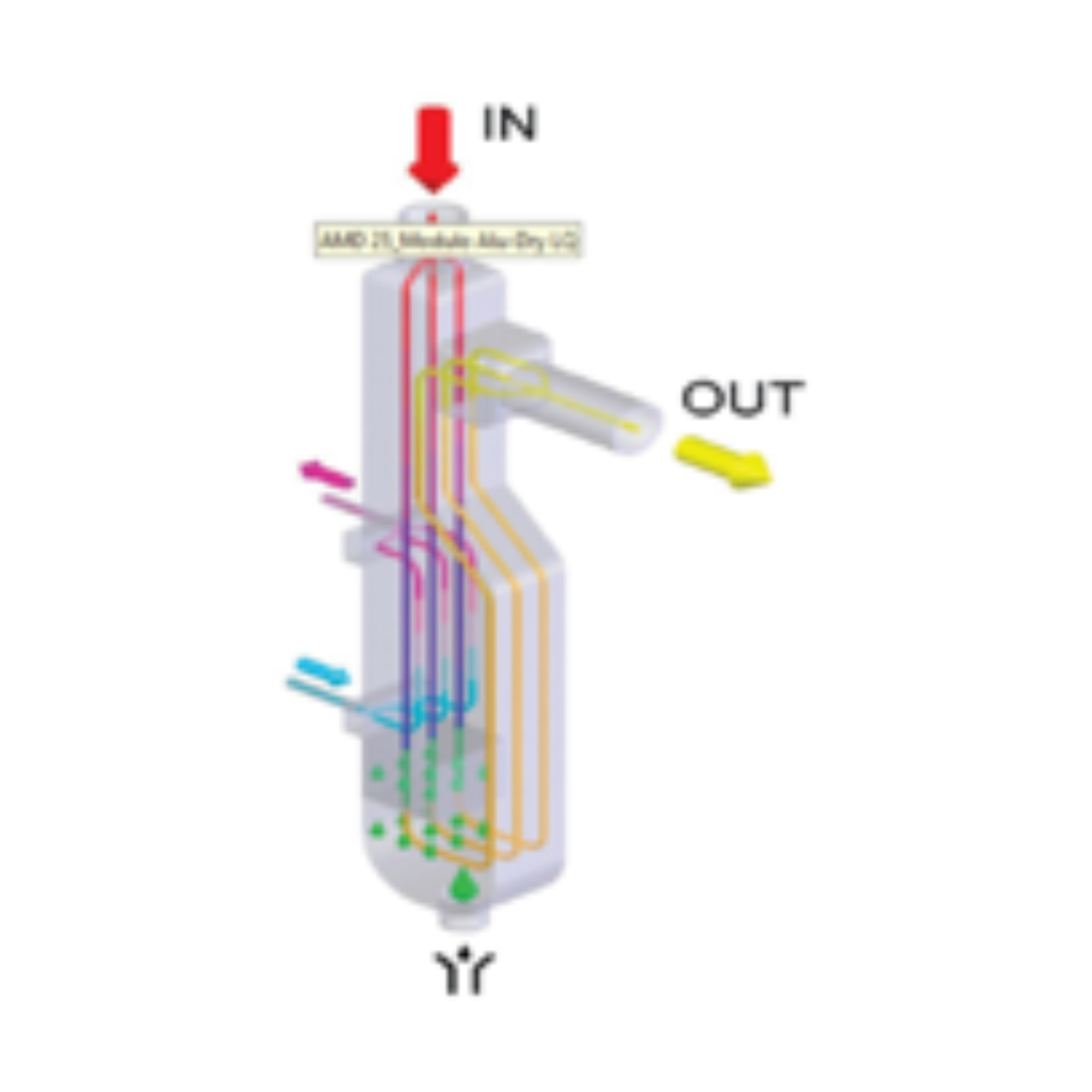

Drying is achieved on the principle of cooling which takes place inside highly efficient and ultra compact 3 stage heat exchanger. In the first stage (air-air heat exchanger) hot and humid inlet air is being precooled by the cold outgoing air. In the second stage (air-refrigerant heat exchanger) intensive water condensation takes place due to cooling the air.

All condensed water is separated from the main compressed air stream in the third stage by integrated demister. A proven and robust design enables efficient and reliable operation, fast installation and simple maintenance.

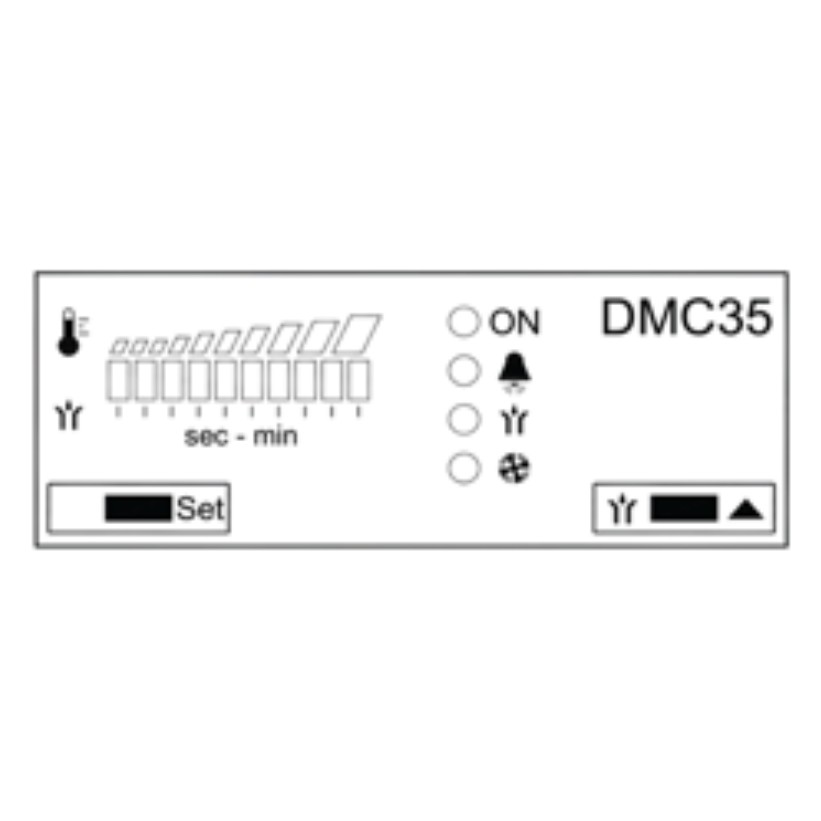

CONTROLLER

Operation of the AMD dryer is monitored by the DMC35 electronic controller which indicates the Dew Point temperature digitally, controls the condensate drain valve via a timer and the condenser fan via a probe.

CABINET

AMD dryer cabinet is built in carbon steel and epoxy powder coated. The case consists of a series of panels which combine to form a strong enclosure, but also designed to allow for easy accessibility just by removing a few screws from lateral panels.

ALU-DRY HEAT EXCHANGER

All AMD Dryers are equipped with Alu –Dry heat exchanger. Its exclusive and patented vertical construction consist in three different parts: Air heat exchanger, Refrigerant heat exchanger, demister area. Generously sized surfaces provide best performance in a wide set of working conditions and a very low pressure drop.

HOT GAS BY-PASS VALVE

The main purpose of hot gas bypass valve is to prevent condensate from freezing on the surface of the evaporator coil when the system is operating at extremely low load conditions.

ELECTRONIC CONTROLLER

DMC 15 controller is fitted as a standard on all dryer models. The controller has brilliantly passed all EMC tests, regarding Electromagnetic compatibility and so it is in compliance with 89/336/CEE and 73/23/CEE Directive requirements, about electromagnetic emissions and immunity.

COMPRESSOR INTERNAL PROTECTOR

Every refrigerant compressor used in an AMD Dryer fits an internal Klixon protect or that shuts off the compressor in case of:

- Electrical over load of compressor’s motor

- Excessive compressor temperatures

This ensures compressor long life and reliability.

SAFETY THERMO SWITCH TS

Starting form AMD 450 Dryer model, a thermos switch (TS) is installed on the refrigerant gas circuit. This component, in case of unusually high temperatures, stops the refrigerating compressor. Thermo Switch has to be manually reset after Dryer nominal operating conditions have been restored.

SAFETY HIGH PRESSURE SWITCH HPS

Starting from AMD 630 Dryer model, on the refrigerant circuit is fitted this high-pressure controller device. It activates when the pressure exceeds the pre-set value, shutting down the Dryer. It features a manual-resetting button mounted on the controller itself.

CONDENSATE DRAIN SYSTEM

A solenoid valve controlled by the DMC35 controller is the standard condensate drain installed in each dryer. The solenoid valve is provided with a bayonet clutch device, designed for easy removal In case of body valve maintenance requirements.

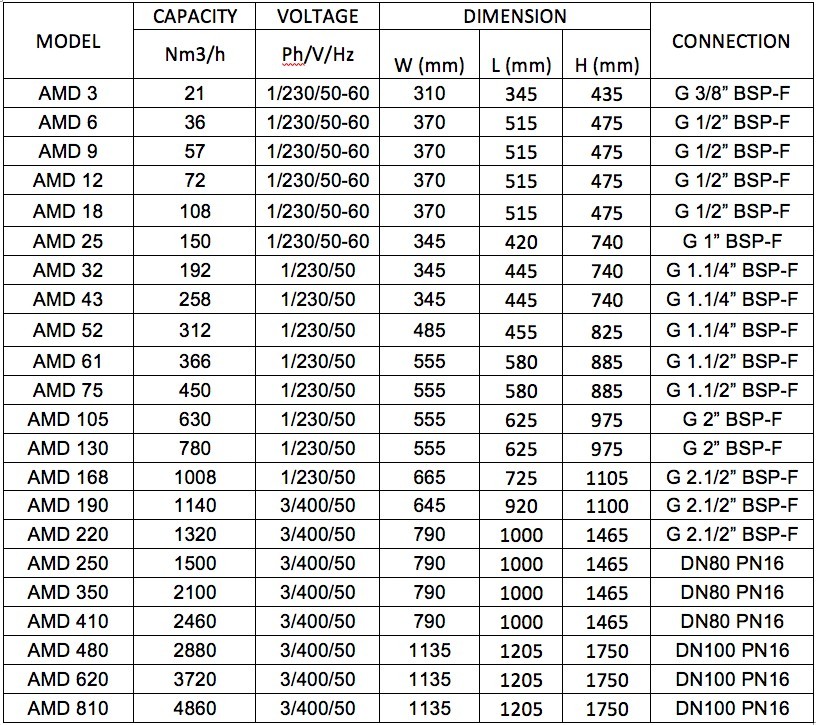

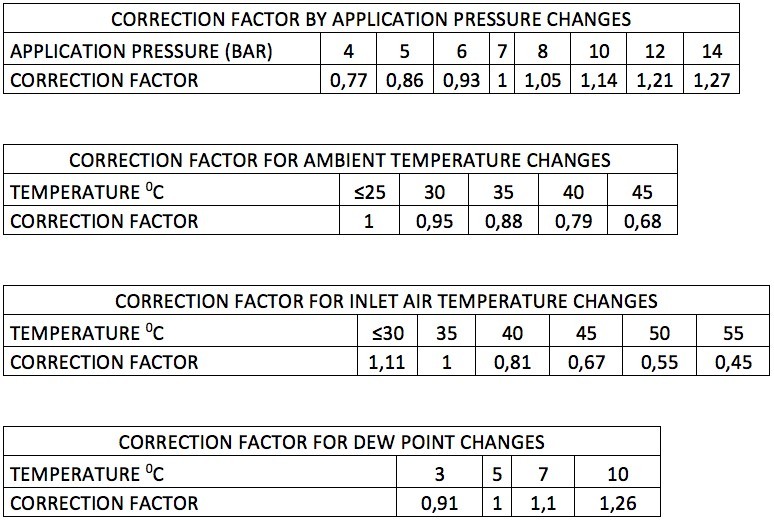

Technical Features:

- Capacity : 21 to 4860 Nm3/h

- Max. Working Pressure : 14 bar

- Max. Ambient Temperature : 1,5 to 45 °C

- Dew Point : 3 °C

- Gas Type : R134a

- Cooling Type : Air Cooled