THE COMPRESSED AIR FILTRATION

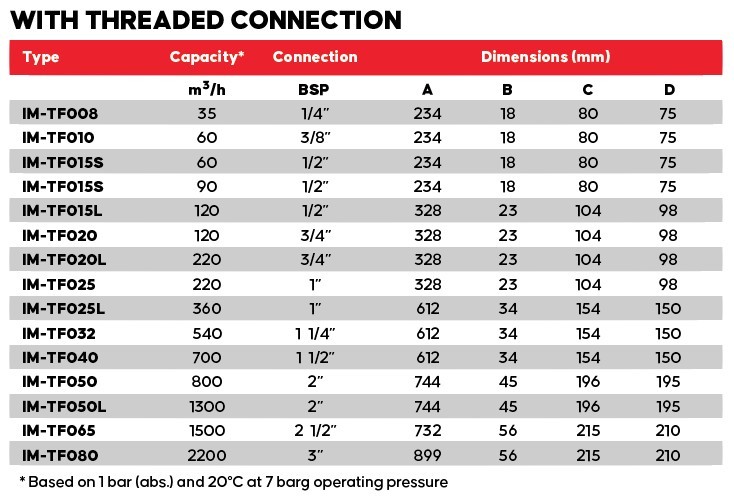

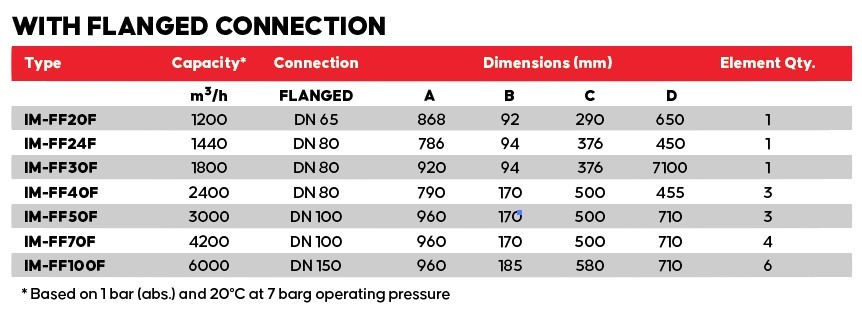

Ideal Makina IM-TF & IM-FF series compressed air filters are designed for the protection of the downstream compressed air system and equipment with lower airflows against defects and other failures.

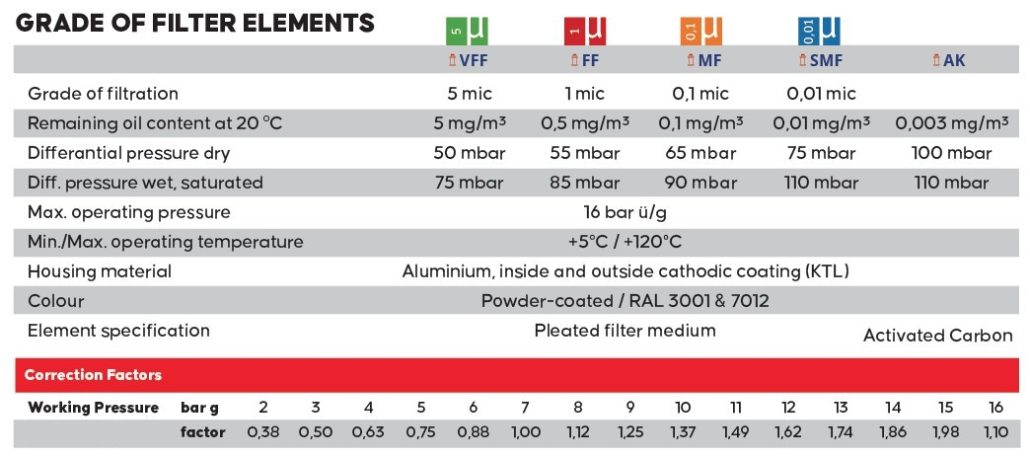

They ensure highly efficient removal of solid particles, water, oil aerosols, hydrocarbons, odour and vapours from compressed air systems up to 16 bar. Required compressed air quality according to standard ISO 8573 can be achieved with 5 different grades of filter elements (VFF, FF, MF, SMF and AK). Optional internal and external condensate drains should be used for efficient condensate draining from the filter housing.

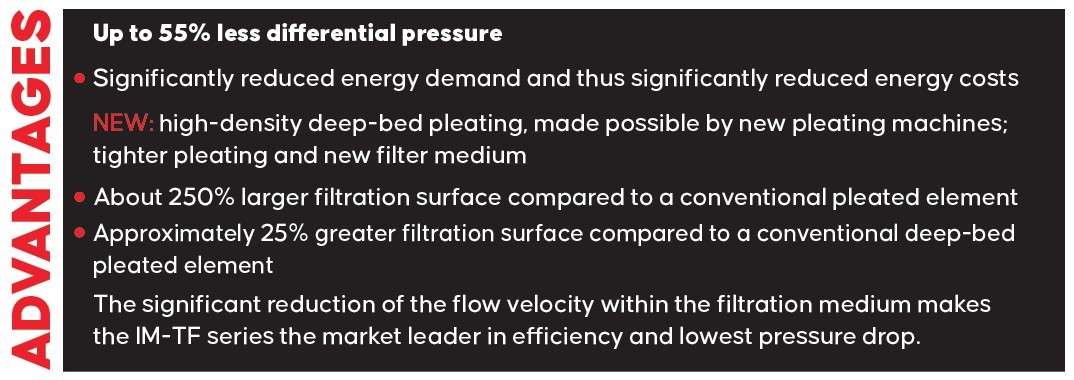

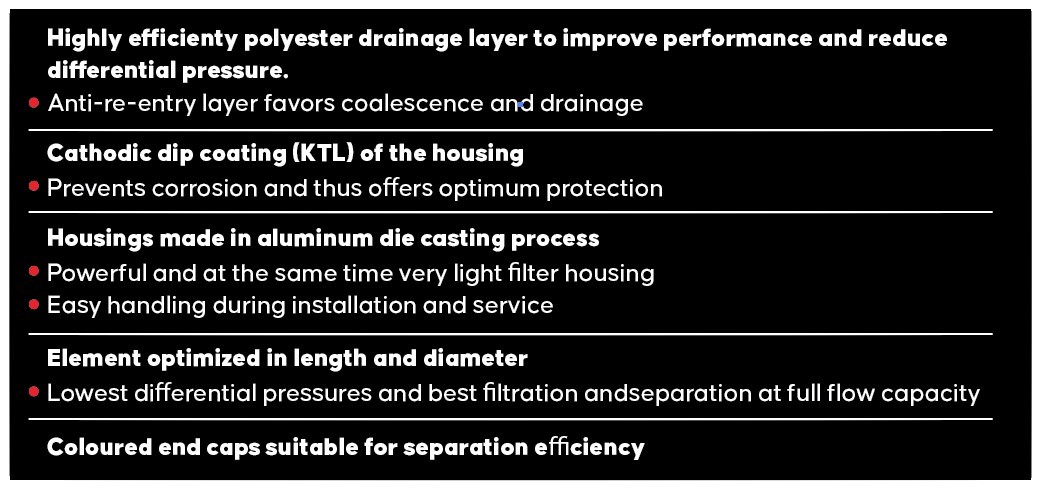

High quality compressed air is always our priority. Quality means less downtime of production processes, leading to your higher profits, and greater satisfaction as a professional in this field. Among other things, the internal and external surfaces of IM-TF series of filters is protected by KTL Cataphoretic coating process as standard. KTL corrosion protection assures excellent chemical resistance to aggressive environment and serves as an excellent primer for external powder paint finish.

The increasing demands of modern production processes also place ever higher demands on the quality of compressed air. Compressors compress the intake air, which contains sub-stances harmful to production, many times over and usually release oils in the finest form as aerosols to the compressed air. In addition, impurities such as fine dust, oil droplets, rust particles, scale, parts of sealing material etc. from the compressed air network are added − and of course condensate (water). Filtration technology of the Ideal Makina IM-TF & IM-FF series protects pneumatic production plants, machines, tools, measuring instruments or products against contamination by means of high-performance filtration.

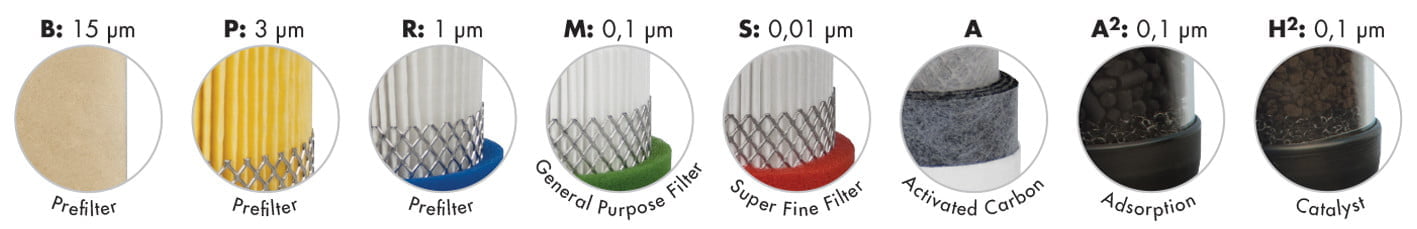

A – The heart of a compressed air filter is its filter insert (element), which must be optimally adapted to the respective requirement, as compressed air filters ensure, among other things, that solid particles, oil components, condensate, oil vapour, odours and much more are safely removed from the compressed air system.

B – An enormous service simplification: the internal condensate drain, which is inserted into the filter housing with the adapter.

THE FUNCTIONAL PRINCIPLE

WATER SEPERATION

To ensure maximum compressed air quality, a water separator should be installed before using a compressed air filter. This separates condensate using a simple physical principle: centrifugal force. The installation of a water separator not only increases the quality of the compressed air, but also the service life of the downstream filter elements.

CONMPRESSED AIR FILTRATION

Due to the arc-shaped compressed air inlet, the flow through of the filter is optimal: the flow resistance is 75% lower. Filtration takes place through the various layers of the filter element, which is passed through from the inside to the outside, thus removing the unwanted components. After the compressed air filter, high-quality compressed air is now ready for further use.