Walker Filtration Medical Filter Series are produced in hospitals for compressed air lines, atmospheric air sterilization, clinical and laboratory sterilizers, to protect plant assemblies from liquid, solid and bacterial pollution and to meet UK Health Technical Memorandum requirements.

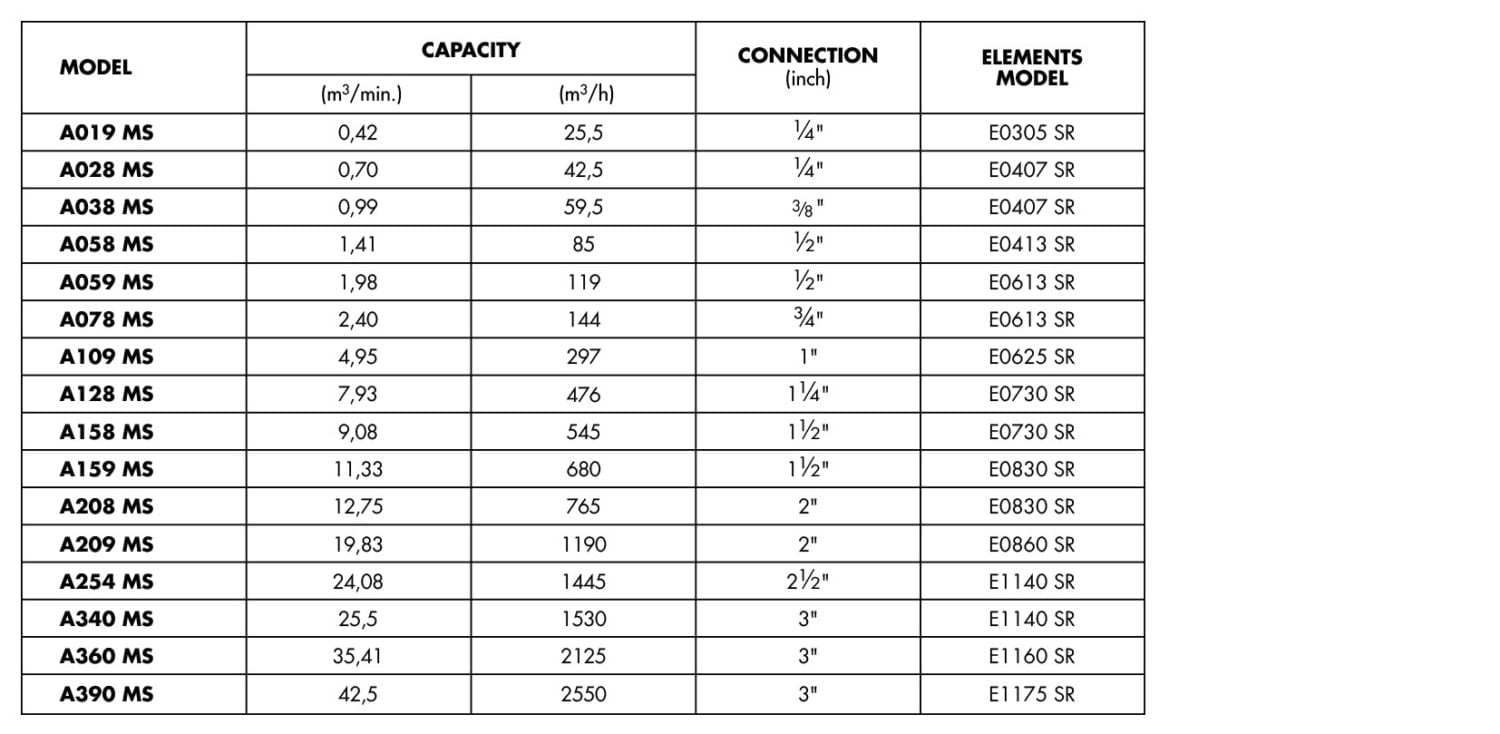

Alfa Series medical sterile filters; It has been designed and manufactured for medical compressed air facilities used in hospitals worldwide. 16 models have been produced to meet UK Health Technical Memorandum requirements for medical gas pipeline systems. These models offer connection between ¼ ”- 3” and capacity up to 2550 Nm³ / h.

It is produced with anti-corrosion Walker E-Coat jacket and cast aluminum providing strength. Thanks to its optimized design, multiple fixed connections are made, making assembly and maintenance easier.

Medical sterile elements that guarantee a minimum of 100 sterilization at 120°C must be autoclaved before use.

Elements are 100% accurate tested and made with stainless steel tips suitable for autoclave sterilization. All elements are supplied with an air sterilization certificate to provide the highest quality to its customers.

STAINLESS STEEL

- Particle Retention: 0.01 micron

- Max. Operating Temperature: 120˚C

- Max. Sterilization Temperature: 138˚C

- Max. Working Pressure: 16 Bar

AISI316 Stainless steel filter elements (cartridges) should be replaced every 8000 hours or once a year.