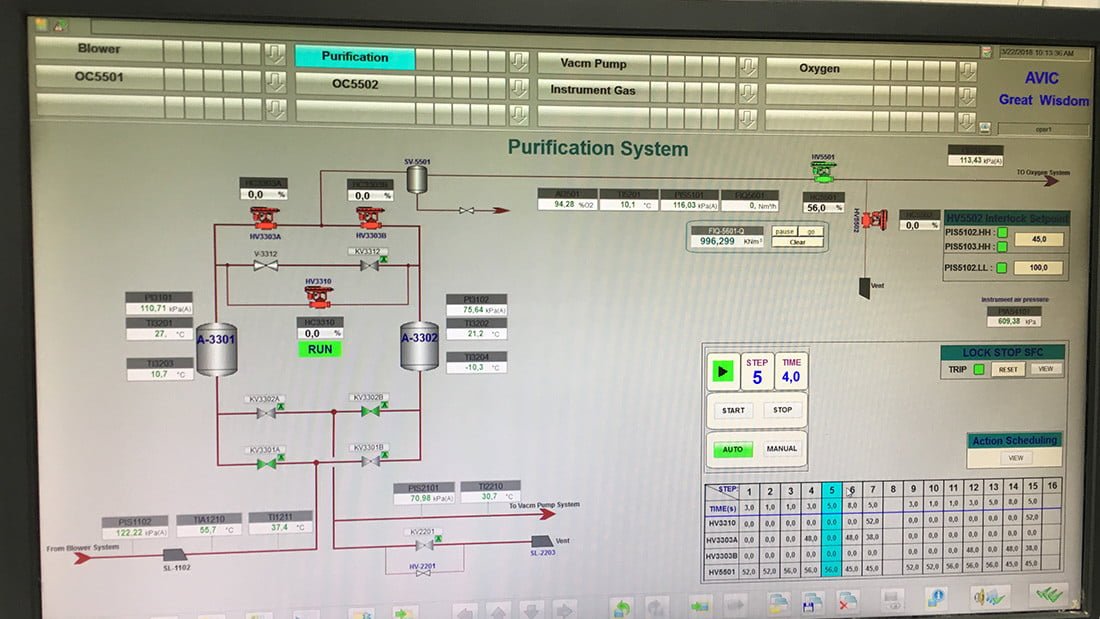

VPSA Oxygen Plants, which are the most efficient method of oxygen production, are created by using equipment suitable for 24/7 operation. The low pressure air produced by a blower is first cooled and dehumidified. Relatively dry air, whose temperature drops to average values, is directed to VPSA tanks. The air, which is directed from bottom to top in a layered structure in the tanks, first passes through the first molecules separated from CO2 molecules and moisture and becomes completely dry here. In the second layer, Oxygen molecules are separated and Nitrogen molecules are retained by utilizing the difference in molecular structure by high-efficiency and long-lasting Zeolite molecules. In the top and the last layer, the flow is regulated and Oxygen Gas is now formed. There is a certain saturation time for each molecule in the tanks, once this period is completed, the fresh blower air is now directed to the other tank. On the other hand, tanks filled with nitrogen and moisture enter the regeneration process with the help of a vacuum blower and the waste gases and moisture are exhausted into the air. In other words, the two tanks work with each other in tandem and continuous oxygen gas flow is provided. The produced oxygen gas is stored in a tank, it is directed to an oxygen compressor according to the needs of the application and it is provided to the facility by increasing the demand pressure.

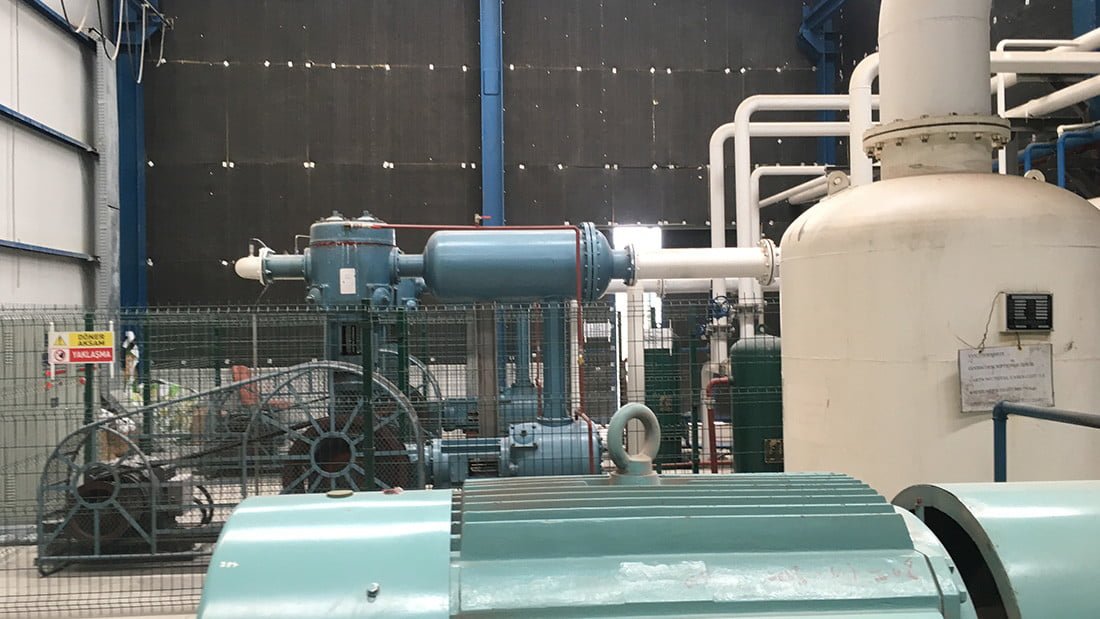

Blower and Vacuum Pump

Roots type blower and vacuum pump create a low pressure environment of 0.49 kPa. Unlike systems with compressors, the biggest advantage of working at low pressures is low energy consumption. In this way, the system equipment does not fall into the pressure vessel class and it is easily installed within the factory.

Adsorber Tanks

The tanks are consisting of 3 layers inside. The molecules in each layer are produced by world-famous companies. In an average system, adsorbent molecules have a working life of 10 years.

Oxygen Compressor

Since the main air source of the system is a blower, a working environment is provided at low pressures. Accordingly, the oxygen gas produced has a pressure of approximately 0.4bar. It is necessary to use an additional oxygen compressor to meet the pressure demands in different applications. Oxygen compressors can pressurize gas at 0.4 bar pressure up to 1.3bar, 2.5bar, 8-10 bar or 40 bar. Due to the burning properties of oxygen, these compressors are chosen as oil-free and piston type. At least 1 primary and 1 spare compressor is applied in each facility.