It is very easy to produce your own oxygen gas and fill your empty oxygen cylinders with Ideal Makina Oxygen Generators and mobile container cylinder filling stations!

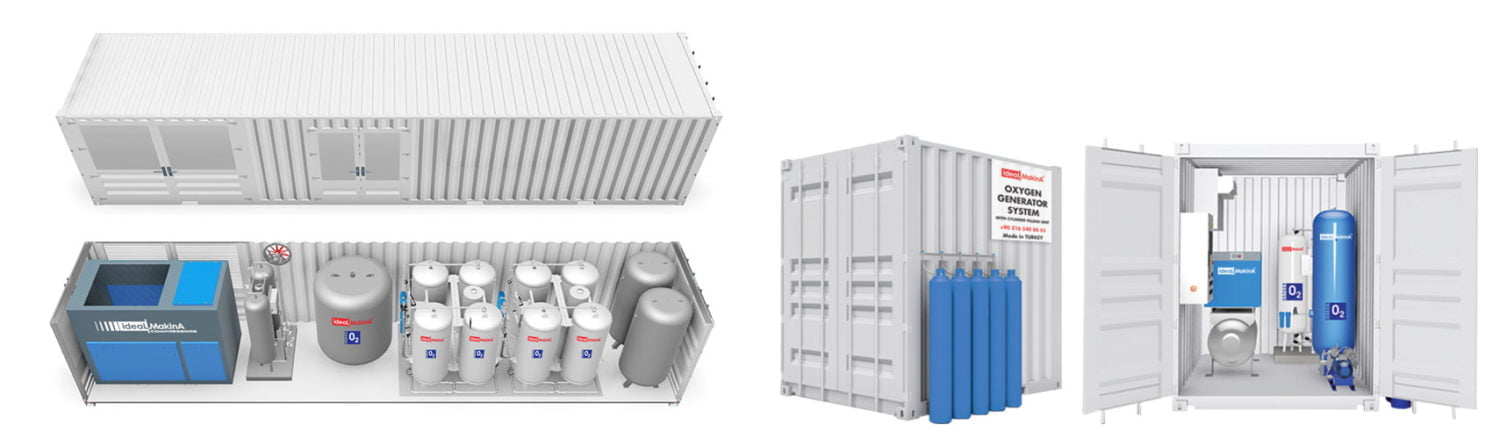

Consisting of high efficiency equipment selected to work together in harmony, the only need for Container Oxygen Generator System is the power connection. It is very easy to produce your own oxygen gas and fill your empty oxygen cylinders with Ideal Makina Oxygen Generators and mobile container cylinder filling stations! By producing your own oxygen gas which is much more economical compared to the cost of your cylinder purchasings, you can fill your cylinders by yourself and can save considerably.

Pipe connections, electrical wiring, main energy distribution together with control panel and all accessories in the container are assembled in the most accurate way and ready to be used. The produced high purity oxygen gas is being filled into oxygen cylinder bundles at 150barg pressure and fully responds to your variable oxygen consumption. These systems are presenting the produced oxygen gas uninterruptedly in the desired quantity, required pressure and high purity.

Deep experience of having installed more than 500 nitrogen & oxygen generator systems for more than 16 years; İDEAL MAKİNA guarantees high quality of Plug & Play Oxygen Generator Systems.

With the container type oxygen cylinder filling station designed by İdeal Makina with a special design, you can produce oxygen gas much more economically compared to your cylinder purchasing costs and can make serious savings!

Please contact us for our container designs that are resistant to all atmospheric conditions and corrosion. They can provide the maximum working performance required for all sound and heat insulated system units.

ADVANTAGES

- Mobile, heavy duty, sound and heat insulated, ISO locked containers

- Ready system with all electrical and mechanical assembles completed.

- Uninterrupted operation in summer and winter equipped with air conditioners and heaters

- Gas production and cylinders filling in any climate conditions on the field

- Factory-tested ”ZERO LEAKAGE”.

- Ease installation and commissioning on site.

- Easy transportation to another place when requested

- Little space usage with its compact structure.

- Main Power Distribution Panel

- User friendly, automatic “START STOP”.

- Environment Friendly Design

- Ability to work with field type diesel electric generators

- All containers have ISO type lifting lugs and ISO locks.

- Suitable for transportation by road, sea and air freight.

- The lower chassis is made of 2/3 tear sheet metal over 100 NPU.

- Cab walls are made of 1,5mm, cabin ceiling is made of 2mm DKP trapeze sheet.

- The cabin insulation is covered with galvanized sheet on 5cm rock wool. In this way, sound and heat insulation is provided.

- G4 dust filter is used in air suction louvers.

- The isolation of the hot air ducts of the compressors is done with aluminum golf sheet on 5 cm rock wool.

- Cabin interior temperature is controlled by air conditioner and fan.

- A Main Electricity Distribution Board available in the cabin where the entire system can be controlled.

- Automatic Fire Prevention and Extinguishing Systems.

- 2 double wing container doors and 1 single wing service door on the cabin.

- Cabine primer paint is epoxy and topcoat is epoxy painted. Paint colour option according to the desired color codes.

- Details such as mechanical and electrical installations, lighting and condensate drain channels completed, all leakage tests are performed and ready for dispatch.