The basic principle of the so-called cryogenic or Air Separation Plant is based on the cooling of nitrogen (78.09%), oxygen (20.95) and argon (0.93) gases in the air to the boiling points and for this purpose, they are separated in liquid phase and presented in high purity. There is a wide range from a small capacity of about 500 m3 / h to high capacity facilities such as 84.000 m3 / h. In the same facility, it is possible to extract oxygen, nitrogen and argon gas, as well as to produce only oxygen and nitrogen only. The facility offers nitrogen and oxygen at the desired pressure in the liquid or gas phase. Liquid oxygen is called LOX, gas oxygen GOX, liquid nitrogen LIN and gas nitrogen GAN.

Turbo Compressor

Designed to meet the high capacity requirement, turbo compressors start from 450 kW and can reach up to a few MW according to the size of the facility. Air Separation Plants (ASU) are indispensable due to the fact that the air it produces is oil-free and can operate for a long time at high speeds.

Air Conditioning

The air produced by the turbocharger is conditioned in two stages. First, its temperature is lowered from the pre-cooling tower and roughly separated from its moisture. It is then directed to an adsorption air dryer, where it is largely separated from all the water vapor in it, all hydrocarbons such as CO2 and C2H2.

Coldbox

Coldbox is usually designed in the form of a high tower, and when seen far away, it makes the air separation plant noticed. It provides cooling of the conditioned air entering into very low temperatures. Gases reaching boiling point in the cooled air are separated from other gases in liquid form. Thus, oxygen, nitrogen and argon are produced in the gas phase. Coldbox contains structures such as high column, low column, argon tower and turbo expender.

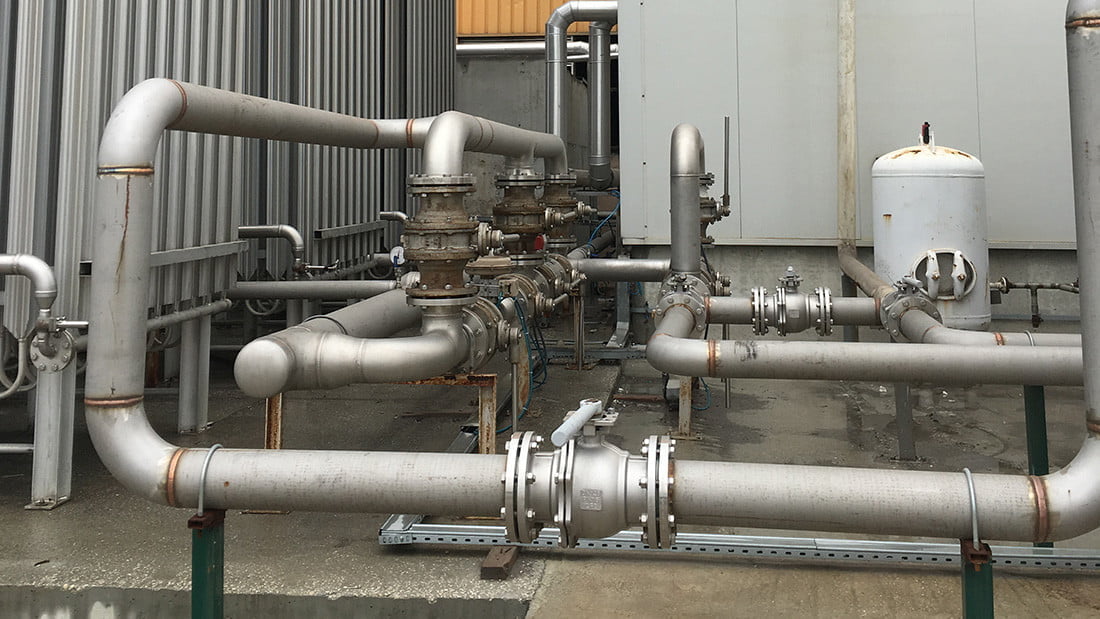

Pressurization and Storage

The gases produced are stored in tanks with a capacity of 1000 L. to 200,000 L., depending on the size of the facility. They can be stored as liquid depending on the needs of the enterprises or they can be stored in the gas phase by passing through the evaporator. Gas pressure can be increased with centrifugal pumps or piston compressors to meet the operational need.