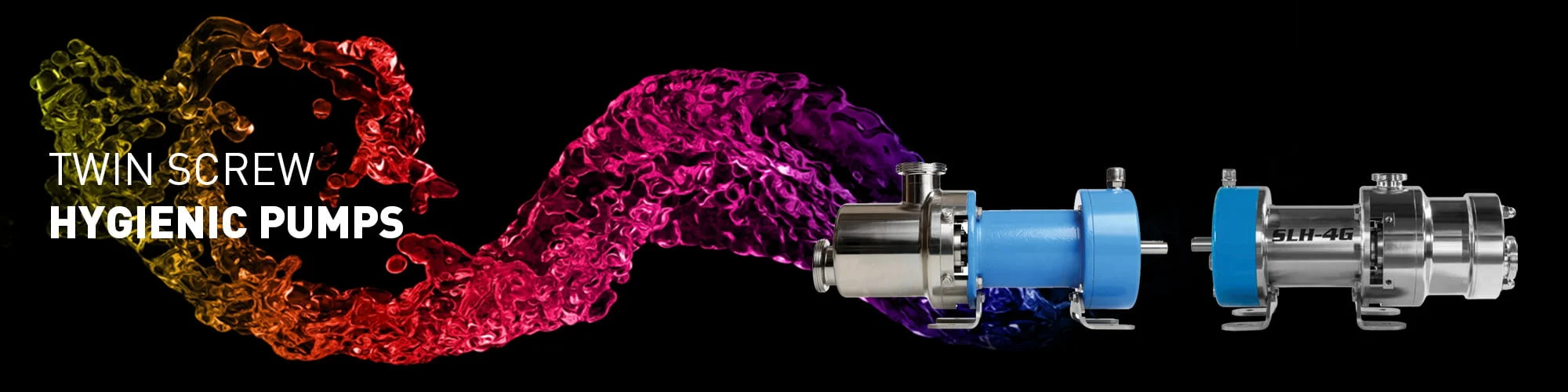

The principle of BORNEMANN twin screw hygienic pumps, move in the opposite direction and are based on the suction of the product with the vacuum power occured in the meantime. Becomes no contact between the moving metal parts and pump body through excellent design. After the pump run, product is vacuumed and got into pump body. The product moves in space between the screws and then is sent to discharge line from pump outlet without any damage or squeeze.

Oil, fruit yogurt, butter, cheese, cocoa, molasses, shampoo, dye etc. fluids will be able to transfer in any viscosity and homogenous without any problem.

During the fluid transfer of the lobe pumps, product is squeezed and product deformations may occur during the transfer due to remaining between lobes. Especially in viscous granular product transfer, granules will be squeezed. For that reason, twin screw pumps are the best solution for especially viscous granular products with no problem. BORNEMANN SLH series pumps are especially designed for food and drug processes.

In these and similar processes which CIP process after the product transfer, if lobe pumps are used in CIP applications, there should be used an external pump. Unless you choose a BORNEMANN twin screw hygienic pump, it’s not necessary to use an external pump. In CIP application, chemical is discharged by the pressure in the pump and line. Thus, line and pump cleaning is provided. According to cycle speed increase, BORNEMANN pumps are designed for CIP cleaning.

BORNEMANN hygiene series pumps are also suitable for dry running with flushing seal application. Thus, during the transfer of fluid, if product does not arrive to the pump, means the pump seal is protected.

TECHNICAL FEATURES:

- Max. Capacity: 400 m3 / h

- Max. Viscosity: 1.000.000 mm² / s (cSt)

- Max. Pressure: 25 bar

- 180 ° C (max) product temperature resistance

- 135 ° C (max) CIP / SIP temperature resistance

- Suitable for Food / Hygiene norms

- 3A, FDA and EHEDG certificates

- Pump structure has suitable for ATEX applications

- Self-priming (0.8 bar)

- Smooth and linear flow feature

- Highly resistant to abrasion

- Dry-running ability

- Can transfer products containing solid particles

- Two-way operation feature

- Suitable for CIP / SIP processes.

- It is a positive displacement pump, capacity is not affected by pressure changes

- It does not harm the products sent. (The surface transfers sensitive products with zero deformation.)

MAIN APPLICATION: