OMAC Lobe pumps are special designed pumps to transfer fluids up to 1.000.000 cps viscosity. It provides transfer of sticky, corrosive or sensitive surfaced fluids as linear, smooth and measurable. It works perfectly at temperatures between -20 and +200°C.

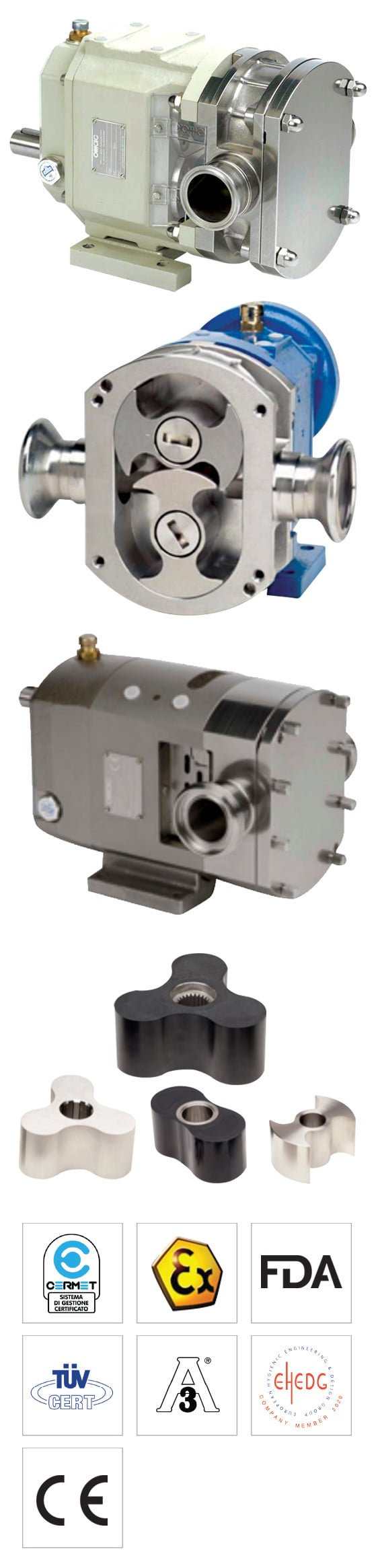

OMAC Lobe Pump consists of AISI 316 stainless dosage head and gear box. Gear box transmits the power from motor to this mechanism. Movement of motor shaft is transmitted to rotor shaft by two gears. All surfaces of contact in fluid are made by stainless material, hygienic pump body comply with food standards. Lobe pumps enable to transfer of viscous fluids without any problem. Different rotor and seal options are available according to fluid viscosity and chemical properties of fluid. Heat jacket types can be used for intermittent processes and in case of fluid tends for freezing. Thus, freezing protection of product in the pump is guaranteed. OMAC lobe pumps are designed as modular, so main parts such as rotor and seals can be changed easily.

Rotors in lobe pumps are moving into opposite direction. During rotation, very precision spaces are between the rotors and pump body. Thus, metal parts does not corrode and not squeeze product. OMAC lobe pumps are proper for CIP (Clean in Place) and SIP (Sterile in Place) used for pump sterilization in especially food and drug industry. OMAC is one of the small numbers of lobe pump manufacturers which have EHEDG – A3 food and hygiene certificates.

TECHNICAL FEATURES:

- AISI 316L stainless steel, titanium and hastelloy material alternatives

- Semi-hygienic, hygienic, super-hygienic and ultra-super-hygienic series

- 1 ”- 8” input-output connections

- Wide-range operating temperature -40°C – 200°C

- Low and high viscosity fluids transfer (max. 1.000.000 mPas)

- Easy transportation of sticky, abrasive or surface sensitive fluids

- Mechanical seal, flushing mechanical seal, double mechanical seal, single and double acting seal

- Options ; Heat jacket, by-pass valve, aseptic, rectangular suction etc.

- Regular, linear, without fluctuations and measurable flow ability

- Compliance with CIP / SIP studies

- 3A and EHEDG food hygiene certified