PET (polyethylene terephthalate) raw material is widely used in the packaging industry. Today, this plastic is preferred not only in the packaging of products such as drinking water, carbonated drinks and oil, but also in the packaging of cosmetics and personal care products.

The raw materials that will form PET are solid and liquid. In the first stage, granules are created from these raw materials and then tubes called as preforms are obtained from these granules. Then, the pet bottle is finalized by the injection-stretch-blow molding process, which has been developed specifically for bottle production. In this process, high pressure air is needed. The required pressure is usually in the range of 20-40 bar. Boge FLEXPET systems can be designed as oil injected or oil-free as the quality of the air demanded may differ depending on the product to be packed.

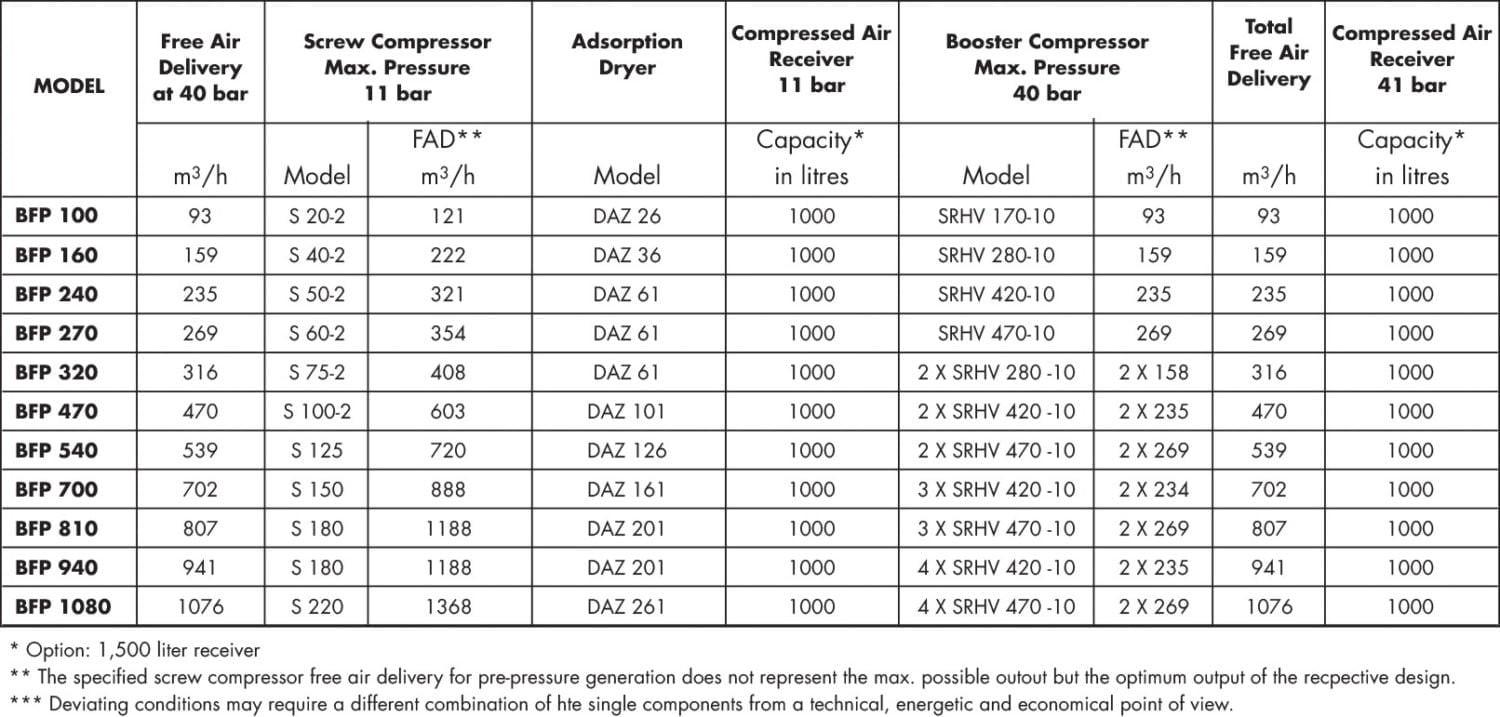

With its flexible structure, BOGE FLEXPET provides the right compressed air system that is optimally adapted for each PET bottle size. Different components are installed separately for the customer’s requirements and environmental conditions. A screw compressor produces booster compressor inlet air at 11 bar with a chemical dryer with a pressure dew point of -40°C. Booster compressor air, is being compressed to higher bar pressure requirements of max. 40 barg. In this way, unnecessary high pressurization is prevented for energy saving.

- IdealMakinA screw compressor for air production at 11 bar pressure

- Cyclone water separator with automatic condensate thrower

- Heatless chemical air dryer with inlet and outlet filters (-40°C pressure dew point)

- Low pressure air vessel – 11 barg.

- Dry and technically oil-free air outlet

- Screw compressor or high pressure booster compressors that bring air from your existing compressed air line to 40 bar pressure

- Airtelligence moster control unit

- High pressure air vessel – 40 barg.

- High pressure cooled air dryer and automatic condensate drain

- Filter station providing dry and technically oil-free air, consisting of fine filter, micro filter and activated carbon filter