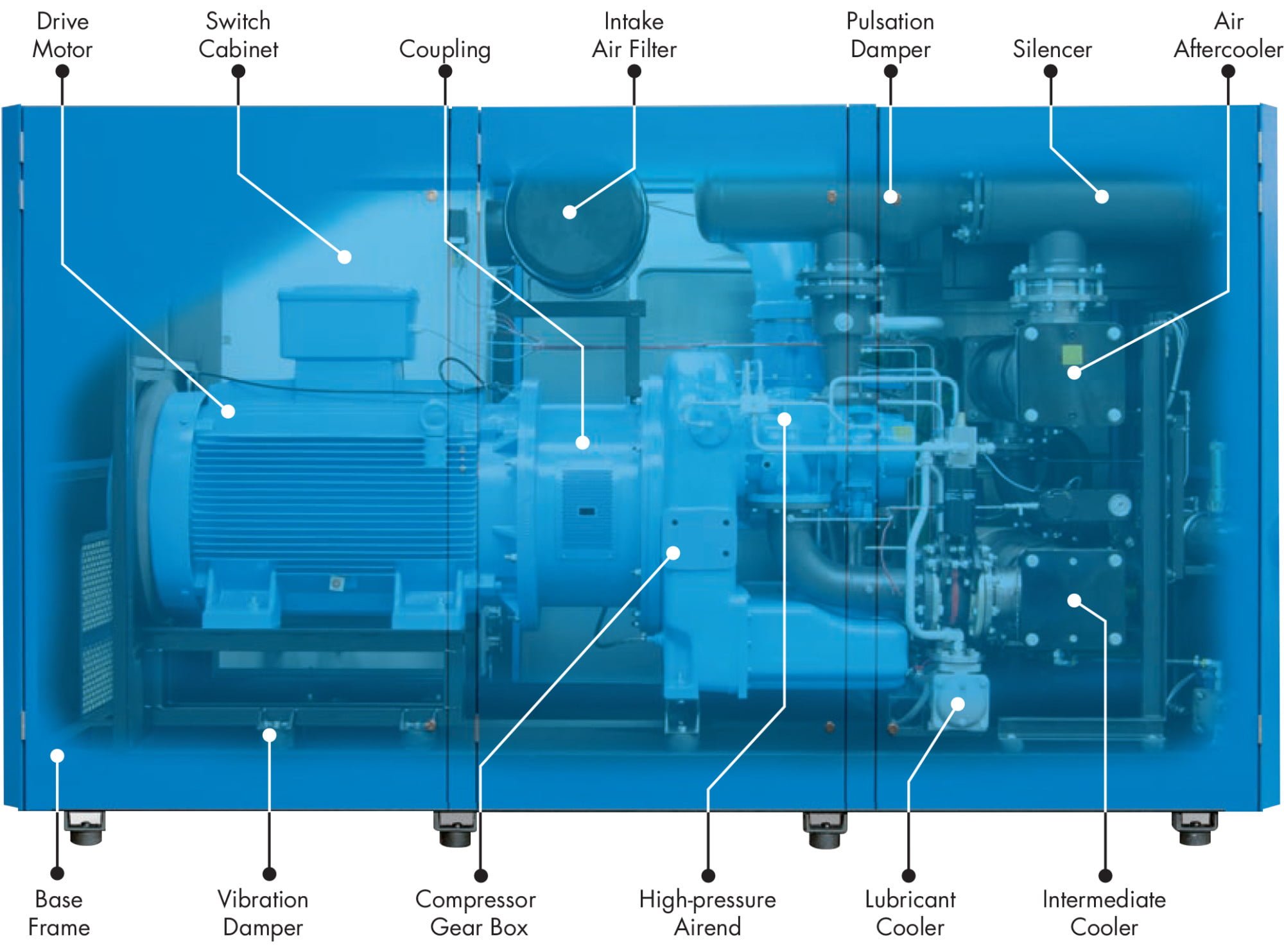

SO series has simple design, quality workmanship and innovative working principle. Screw compressors in this series produce oil-free compressed air with clean, efficient and maximum reliability. This situation makes these compressors ideal for critical industries such as the pharmaceutical, food and semiconductor industries. The frequency control unit adjusts compressed air production to your net demands.

Oil-free screw compressors are based on a principle whereby the cooling and lubricating role of the oil is replaced by innovative functional principles. Central to this are the special compression stage and the BOGE cooling concept. Both are designed to offer the highest safety level with the maximum efficiency.

MOTOR

These models are equipped with a three-phase asynchronous motor, ISO class F with additional motor reserves to meet the most challenging operating conditions. The motor is installed in the cool air intake section of the package and is thermistor protected to ensure a long service life.

WATER COOLING

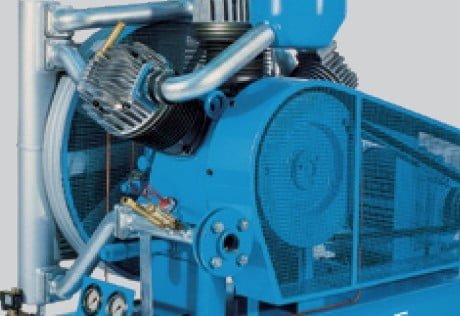

Where large volumes of air are required water-cooling is a must. The intelligent BOGE cooling concept guarantees safe and economical cooling of the compressor with optimum maintenance friendliness.

EXHAUST AIR COOLING

As an option the SO series can be equipped with a cowl cooler eliminating the need for expensive exhaust air ducts.

PRIME CONTROL

The PRIME control is the latest state-of-the-art energy effi cient controller to come from BOGE. A large-scale back-lit LC display with clear text information shows error/ maintenance messages, operating status and all operating parameters on three main menus.

EXTREMELY QUIET

The SO-2 machines are equipped with a combined sound and pulsation absorber. Because of its intelligent design and the use of powerful sound absorbing materials the entire range operates quieter than ever before.

HIGHEST EFFICIENCY

The cooling air fl ow of the SO-2 machines has been substantially optimised. The air intake from the coolest area and the minimisation of pressure losses additionally increase the free air delivery with a low specifi c power consumption

SAFE AND SERVICE FRIENDLY

Particular importance was given to optimise accessibility of maintenance intensive components (e.g. cooler and oil cooler) during the design of the SO-2 machines. An additional separator was integrated to improve intermediate separation – for absolutely safe operation.

FLEXIBLY CONNECTING

The raised position of the compressed air outlet does not require any risers and allows for problem free connection of additional components: e.g. external aftercooler, cyclone separator, fi lters and dryers.