Chemical dosage systems are the systems required for businesses to make dosing with the precision they need for their processes.

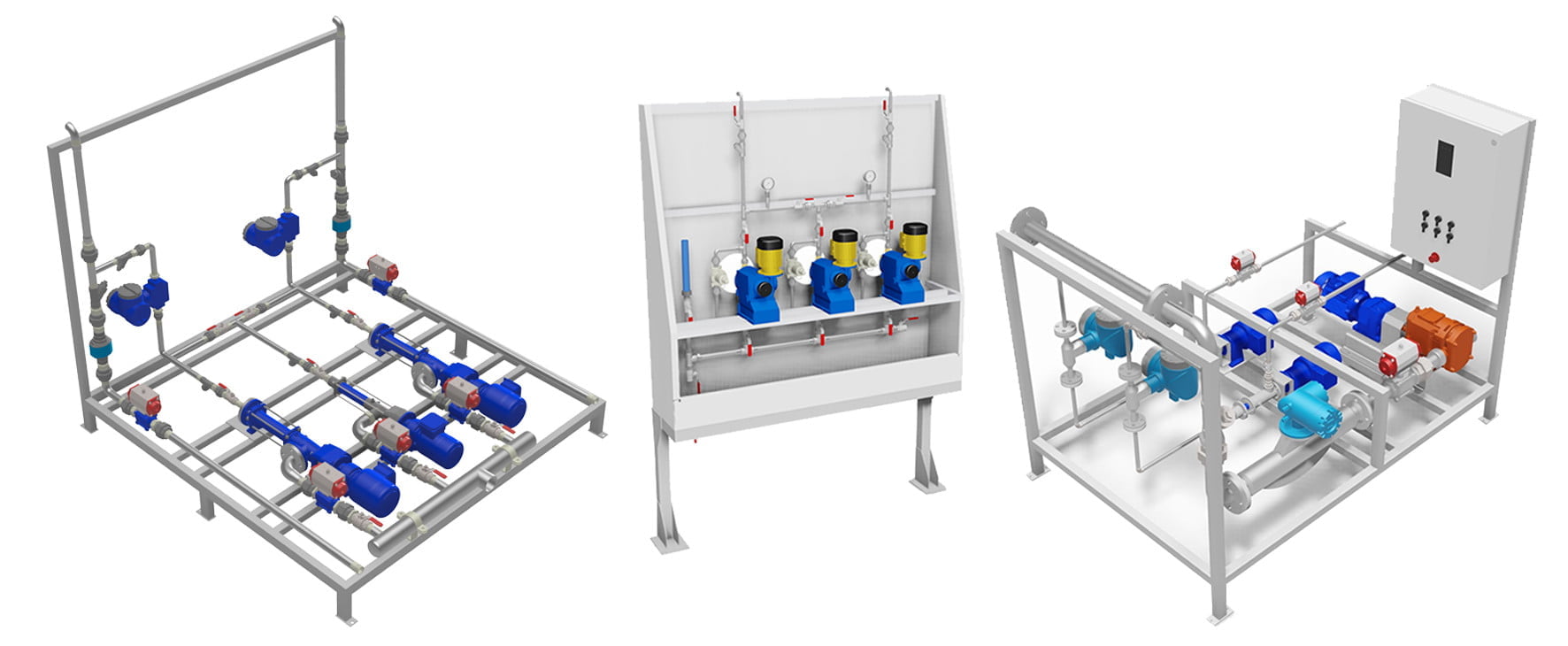

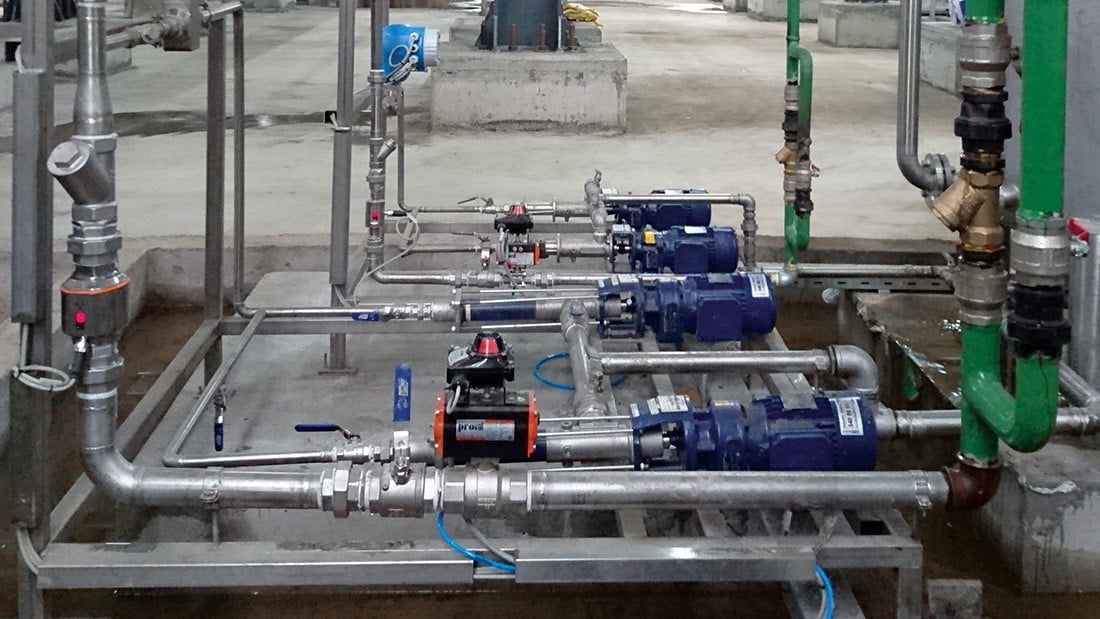

The key system realized with dosage and transfer pumps, chemical storage tanks, measurement control instruments, automation and electrical control systems, all piping and necessary line accessories and instruments are called skid systems and are produced by İdeal Makina specifically for the process.

These systems have been developed for companies to save water and use chemicals more effectively. The fact that the cooling water can remain in the desired quantities ensures that the amount of chemicals supplied is reduced with the automatic measurement control and dosage system. These systems, apart from chemical consumption, also ensure that the clean water, which has become more important in recent years, is used in the right amount and is not wasted.

With skid systems, measuring the chemical to be dosed with a flow meter and instantly transmitting the values to the operator, liquid, temperature, ph, conductivity etc. It is produced in the form of systems mounted on the chassis that provides the signal to the dosage pump by measuring parameters such as.

With the programming made by the expert staff of the Ideal Machine, values such as how much chemical is given to the system, how long it is left in stocks, etc. can be viewed, controlled, and also carried to the computer in the room where the operator is located, and instant reports can be received.

Dosing systems are produced in accordance with the process needed by the company and the location desired.

SCADA (Supervisory Control And Data Acquisition) “Merkezi Kontrol ve Veri Toplama Sistemi kontrol ve otomasyon mimarisinin en üst katmanını oluşturan ve operatörlere sistem kullanıcı ara yüzü sağlayan önemli bir yazılımdır. Otomasyon sistemleri, kısa zamanda daha fazla ve kaliteli ürünün, düşük maliyetlerle üretilmesi ve üretim esnasında hataların asgari düzeye indirilmesinde önemli rol oynamaktadır. İdeal Makina, anahtar teslim çözümleriyle sistemlerini uzman yazılım kadrosu tarafından oluşturulan SCADA ve PLC otomasyon yazılımları ile sistemlerini tamamlamaktadır.”

SCADA (Supervisory Control And Data Acquisition) “Merkezi Kontrol ve Veri Toplama Sistemi kontrol ve otomasyon mimarisinin en üst katmanını oluşturan ve operatörlere sistem kullanıcı ara yüzü sağlayan önemli bir yazılımdır. Otomasyon sistemleri, kısa zamanda daha fazla ve kaliteli ürünün, düşük maliyetlerle üretilmesi ve üretim esnasında hataların asgari düzeye indirilmesinde önemli rol oynamaktadır. İdeal Makina, anahtar teslim çözümleriyle sistemlerini uzman yazılım kadrosu tarafından oluşturulan SCADA ve PLC otomasyon yazılımları ile sistemlerini tamamlamaktadır.”

SCADA Sisteminin uygulamada sağladığı avantajlar:

- Kullanıcı tarafından tanımlanmış, işletmeye ait parametreler (kapasite, basınç, seviye, sıcaklık, dijital sinyaller, vana ve motor durumları, sistem durumu vb.) vasıtasıyla işletmenin takibini sağlar.

- İşleyen reçeteler hakkında operatörün bilgilendirir.

- Parametre ekranları vasıtasıyla, sistem için gerekli olan limit değerlerin girilmesine olanak sağlar.

- İşletme değerlerinin tarihsel ve gerçek zamanlı takibinin yapılmasına olanak sağlar.

- Anlık ve periyodik raporlama alınabilir.

- Otomatik çalışan sisteme, SCADA ekranlarından manuel müdahale imkanı sağlar.

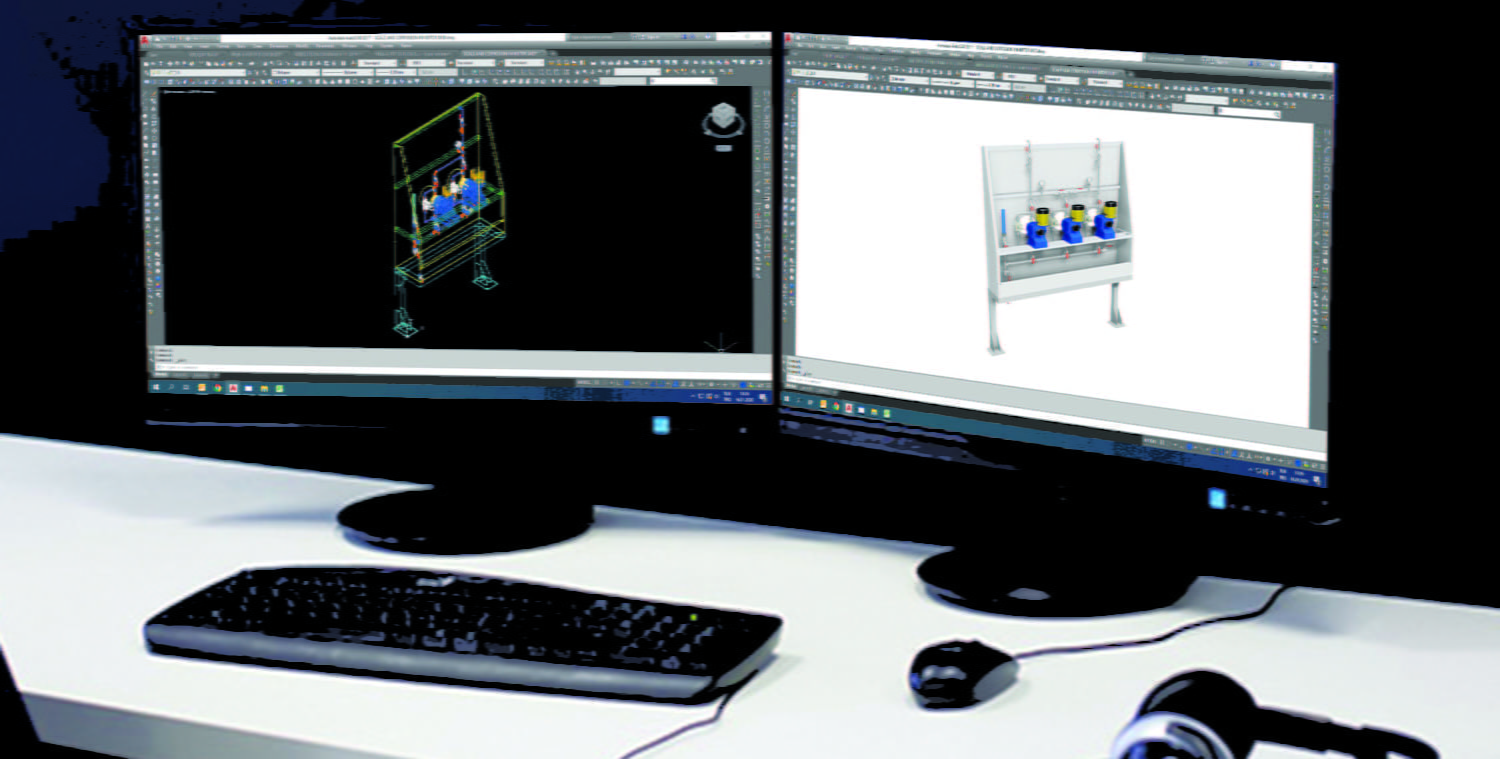

The chemical dosage skids you need are primarily designed in our 3D drawing program. After agreed with the customer, the manufacturing process is started. Thus, you can be sure of the system you will purchase by seeing the 3D drawing of the dosage skid you need before starting production. Dosage skids manufactured after being agreed with the customer are tested in our own workshop before delivery.

• Mining • Chemistry • Petrochemical • Wood-Paper • Purification • Biogas • Energy • Food

• Cosmetics • Pharmaceutical • Plastic • Aluminium • Textile • Paint • Medical • Fishery

• Marine • Water & Environment