High quality and performance products for compressed air treatment by Ideal Makina…

Producing compressed air in right quality is the most important issue for users. If contaminated air is in contact with the equipment and final product in the production process, it will cause to deterioration of the equipment and increase the product costs which can greatly increase the operational costs.

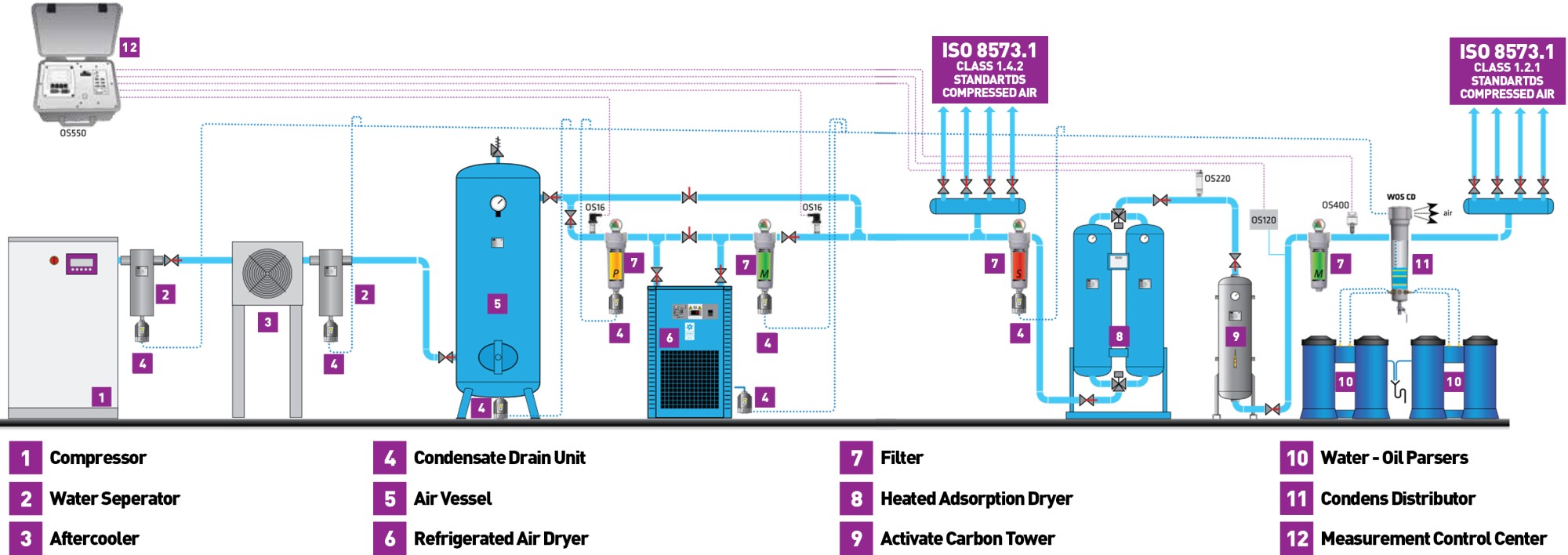

It is very important to set up the system by determining the required air quality in accordance with the quality policy of your company and determining the requirements of the compressed air system according to this need.

There may be a variety of undesirable contaminants in the compressed air, such as water vapor, oil, particles, dust, etc. Depending on the application area of the compressed air, these undesirable materials reduce the quality of the produced product and increase the cost.

The quality of the compressed air should be determined with various dryers and filters for customer’s air quality requirements.

COMPRESSED AIR STANDARD

Compressed air quality is defined and classified as below table by ISO 8573-1: 2010 standard. This classification evaluates the contaminations contained in the compressed air under 3 different titles according to the particle size and number, the amount of water and the amount of oil.

The quality of the compressed air is expressed in the figures in the table above. For example; Class 1.2.2 means

The quality of the compressed air is expressed in the figures in the table above. For example; Class 1.2.2 means

1. Quality in terms of the amount of particles left in each m3 air

2. Quality with -40°C Dew Temperature in terms of remaining water vapor

2. Quality in terms of the amount of oil remaining in 1 m3 air

By consulting our expert engineers, you can get detailed information about our compressed air solutions suitable for your need!