Moisture capacity increases due to the heat of the air exposed to the compressing process in the compressor. Compressed air reaches very high temperatures, especially in regions with a hot climate and needs to be cooled depending on the point of use.

Through OMEGA Aftercoolers, compressed air, which is reduced to the temperatures to be used more efficiently, is separated from the condensate by up to 80% during this cooling process. There are water or air cooled models available working in the same principle.

The aftercoolers used before the compressed air dryers guarantee more efficiency and stable operation of the dryers integrated afterwards.

Aftercoolers that are used before the refrigerated air dryer; significantly reduces the energy spent for the cooling cycle and prevents capacity losses due to high temperatures in summer. Also when used before the adsorption chemical dryers, it saves purge air by extending the absorption time of the desiccant material. In newly planned compressed air systems, aftercoolers to be included in the system generally reduce the initial investment cost significantly. Maintenance and spare parts costs of aftercoolers are almost non-existent. Operational expenses are very small compared to their functions.

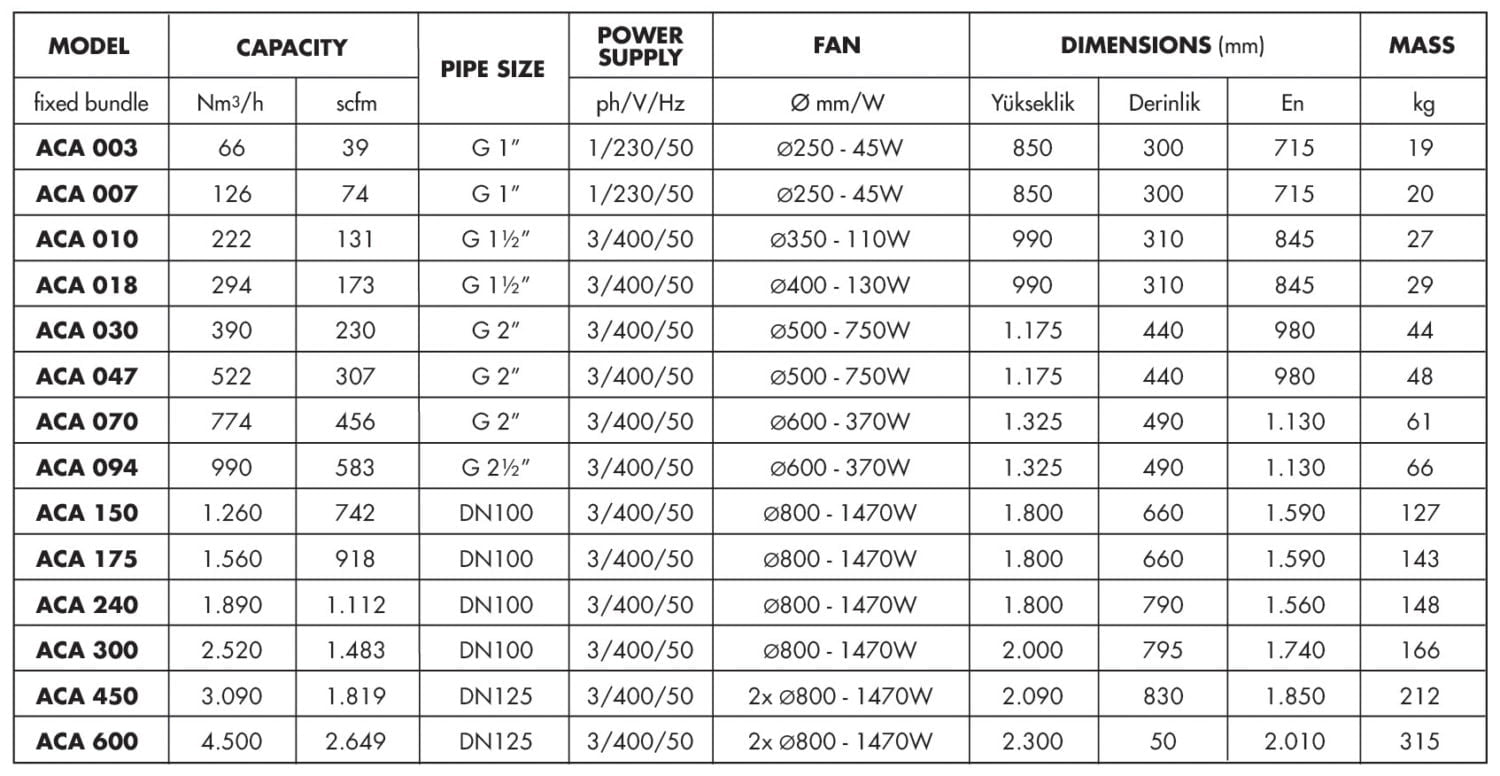

AIR COOLED

- Operating Pressure: 15 bar

- Inler Air Temperature: 120ºC

- Max. Inlet Air Temperature: 170ºC

- Flow Rate: 66 – 4.500 Nm3/h

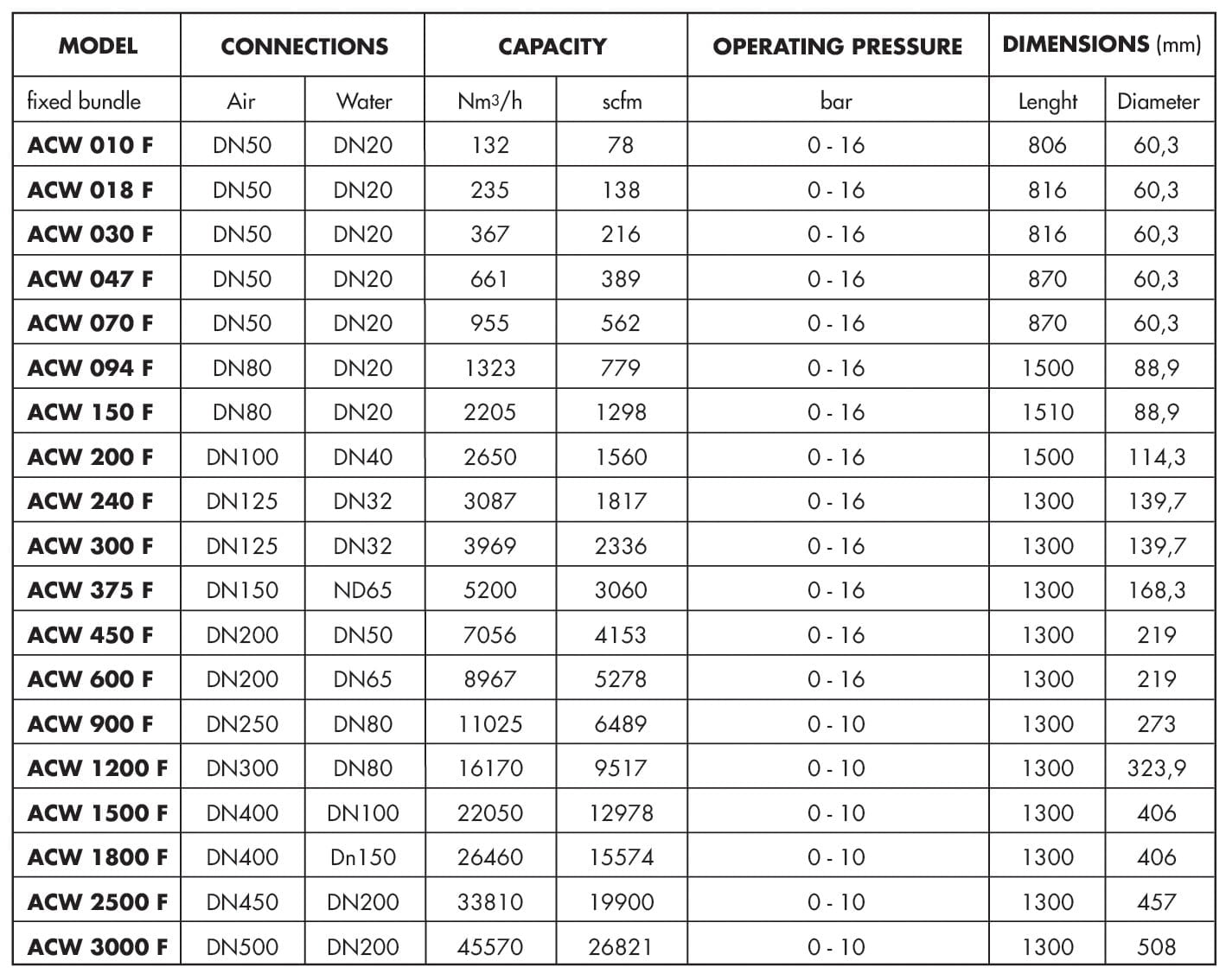

WATER COOLED

- Operating Pressure: 16 bar

- Inler Air Temperature: 1,5ºC – 200ºC

- Max. Inlet Air Temperature: 170ºC

- Flow Rate: 132 – 45.570 Nm3/h