The nano Breathing Air Systems (NBA) range of medical compressed breathing air purifiers are designed to provide a continuous supply of breathable air to meet the most exacting standards world-wide. The unique design provides a major step forward in compactness by incorporating several stages of purification in one simple to service cartridge, reducing the cost of ownership and simplifying maintenance.

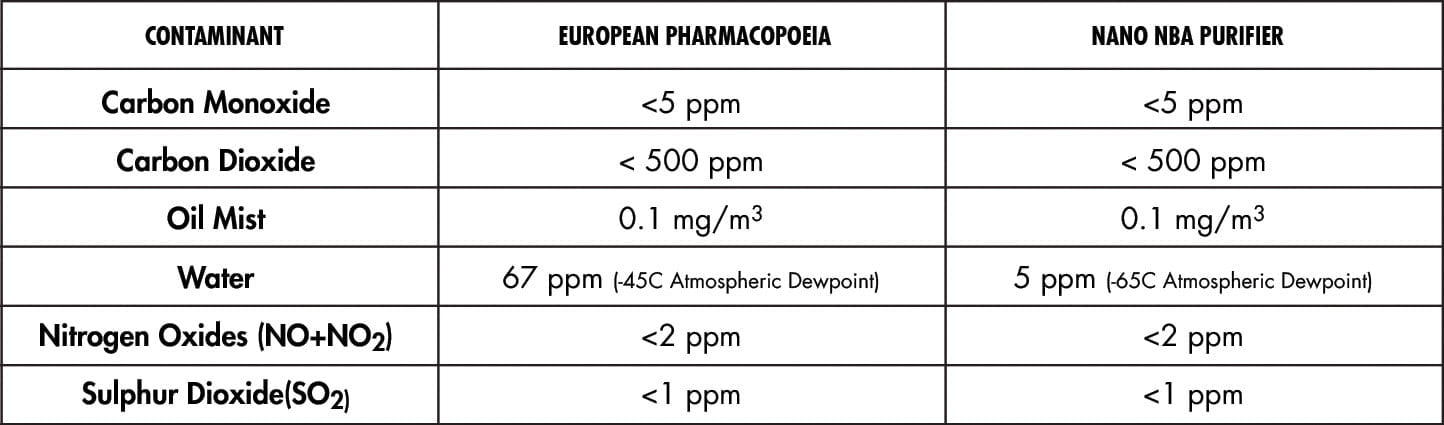

Atmospheric air contains a number of contaminants which must be removed to ensure the provision of high purity breathable air. Contaminants present include dirt, water, oil, hydrocarbon vapors, bacteria and toxic gases such as CO, NO2 and SO2.

All Nano Breathing Air Systems are produced in accordance to the following standards.

- Breathing Air: BS EN 12021:2014

- Medical Air: European Pharmacopoeia 5.0-Monograph 01/2005:1238

The nano breathing air purifier employs a number of purification stages to ensure breathable compressed air is produced from a typical compressed air supply. Inlet filtration removes dirt, bulk water and oil aerosols (if an oil lubricated compressor is used). Water vapor and hydrocarbon vapors are removed by selected adsorbents and CO2 reduces to within specified levels. CO is removed by a catalytic stage and finally all residual dust and bacteria are removed by the integrated high efficient outlet filter. Internally, should any bulk liquid enter the purifier, they will be separated and safely drained away by reliable solenoid valves that are also used in the operation of the pressure swing adsorption process.

How the breathing air NBA purifier works?

The nano breathing air purifiers use the pressure swing adsorption principle to efficiently purify the compressed air. They consist of a twin tower configuration of modular construction. Each tower contains a composite purification cartridge which incorporates various types of selected materials to remove impurities to within the required levels.

Moist contaminated air enters the purifier and is first directed to column A. The air passes into the purification cartridge where water vapor is adsorbed and the air dried to a level that enables the CO to be converted to CO2 by the use of a catalyst. CO2 content is also adsorbed to ensure the outlet purity is achieved but enough is left for respiratory purposes. Hydrocarbon vapors, NO2 and SO2 contaminants are now adsorbed using a selected high surface area activated carbon stage. Finally the air passes through a high efficient filter stage to remove any solid particles and bacteria. Simultaneously, a small amount of purified air is de-pressurised and counter flowed through Column B and exhausted to atmosphere, removing the moisture and excess CO2. Hydrocarbon vapors NO2 and SO2 are retained on the activated carbon stage through chemisorptions. Column A typically operates for 2 minutes while column B is under regenerations (1 ½ minutes of purge and then repressurised) prior to the columns being switched over, which brings Column B on line and Column A goes into regeneration.

The breathing air purifier is controlled by a robust PLC which switches the solenoid valves allowing each column to be switched from purifying to regeneration thus providing a continuous stream of purified breathing air.

ADVANCED CONTROL

- Advanced PLC controller with digital display

- Displays pressure dew point (ES option)

- Display of run hours, column in use

- Indicators: Power “on” / Service required / Hours run

- Volt-free contacts for external alarm warning

- On/off switch

- Service alarm light and flashing display

- Universal voltage power supply

HIGH RELIABILITY

- Reliable & robust coaxial flow valves

- Inlet, exhaust & outlet valves are integrated into the upper and lower manifolds

- Unrestricted flow capacity

- Designed for durability

- Easy to maintain and service

- Long service life

- Commonality of parts for smaller inventory levels

- Quiet operation

FLEXIBILITY

- Simplicity of service in mind

- Layered high density filled combination columns

- Desiccant

- Activated Carbon

- Catalyst

- Integrated particulate after filter

- Pre-filled multi layer cartridges

- Easy to maintain and service

ENERGY SAVING DESIGN

- This unique control feature monitors outlet pressure dew point to reduce energy consumption during periods of low demand.

- Saves valuable compressed air

- Reduces wear on supply air compressor and dryer

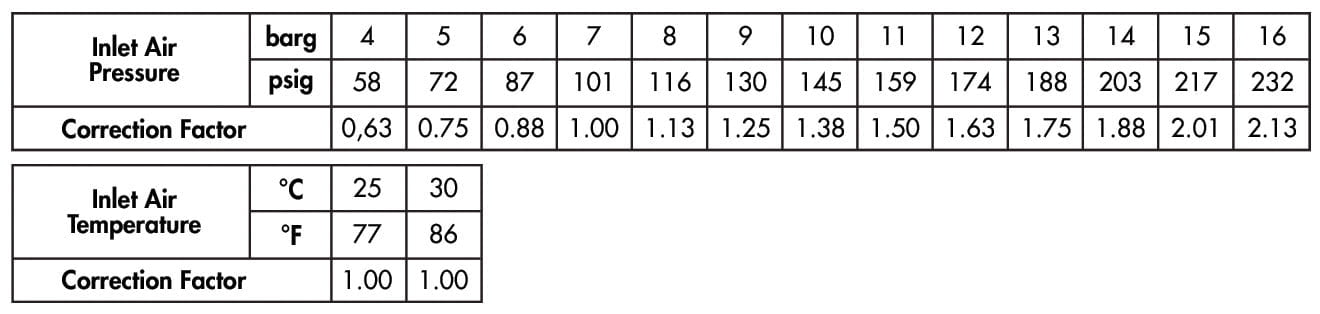

- Maximum Water Content (ISO 8573.1): class 2 -40°C (-40°F) pdp

- Minimum Operating Pressure: 6 barg (87 psig)

- Maximum Operating Pressure: 16 barg (232 psig)

- Recommended Operating Temp Range: 1.5 to 30°C (35 to 86°F)

- Design Operating Temperature Range: 1.5 to 30°C (35 to 86°F)

- Power Supply Requirements: 100 to 240V AC @ 50 or 60 Hz

All purifiers should be proceeded by a coalescing filter regardless of oil or oil free applications, a 0.01mg/m1 grade coalescing filter must be installed on the inlet to the purifier.