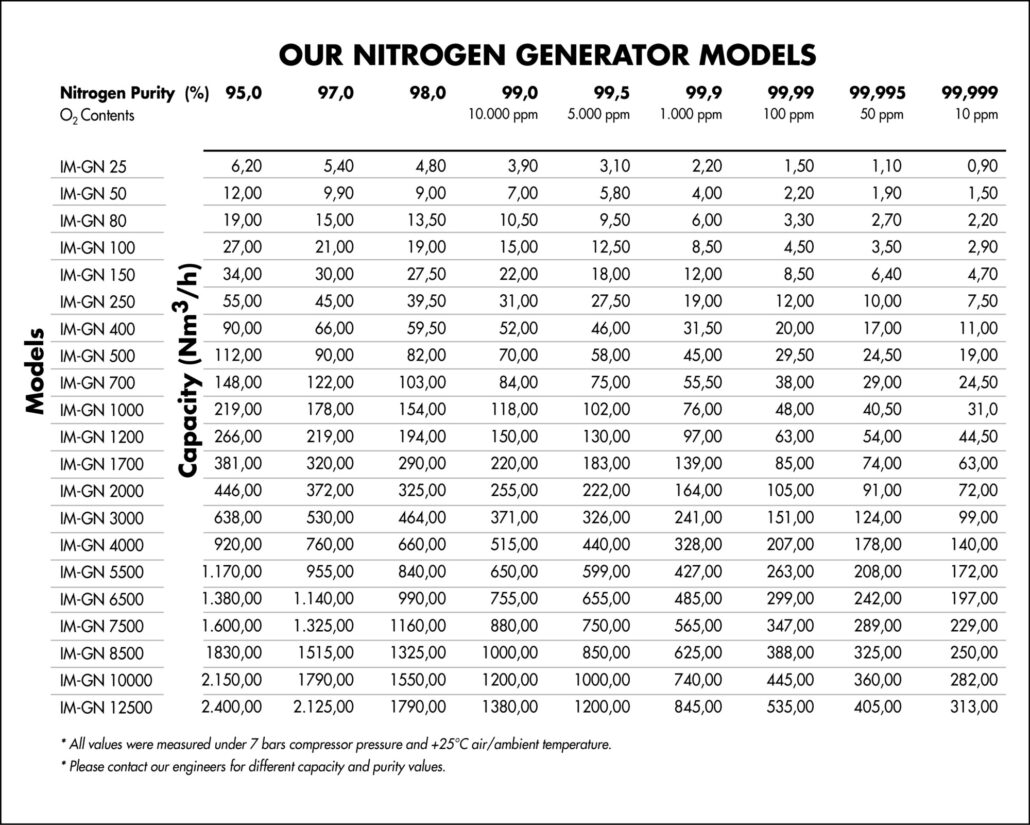

Through the PSA technology being applied, IDEAL MAKINA produces nitrogen generators up to 95% – 99.9999% (1 ppm) purity in the range of 0.5 – 5,000 Nm3 / h with 30 models.

IDEAL MAKİNA has been the leader in the sector since 2005, with more than 500 systems established in the domestic and international markets.

IDEAL MAKINA PSA Nitrogen Generator Systems produce nitrogen in the form of gas from compressed air on-site where they are running and offer a cost-effective, continuous and safe solution compared to traditional nitrogen gas sources such as cylinders or cryogenic liquid. The design is made for 24/7 operation. Each nitrogen generator is equipped with an automatic start and stop function, which allows the user to start and stop automatically according to nitrogen consumption.

Through the developed patented vortex technology, IDEAL MAKINA is providing more efficient air separation by providing more efficient usage of CMS (Carbon Molecular Sieve) in the new GN series nitrogen generators. This leads to be the one and only Nitrogen Generator with the least compressed air consumption in the World.

Use smaller compressors, consume less energy with IDEAL MAKINA Nitrogen Generator.

You can produce your own nitrogen with IDEAL MAKINA NITROGEN GENERATOR SYSTEMS and can forget about your cylinder or liquid nitrogen purchasing costs!

Moreover;

- In the amount you need

- The purity required by your production process

- At required pressure

- Under your control…

You do not only buy oxygen cylinder or liquid oxygen, but you do also buy:

- Safety problems due to high pressure in the cylinders

- Cylinder / liquid nitrogen tank rental

- Transportation costs

- Internal purchase expenses

- Labor costs and risks for cylinder when loading – unloading and transportation.

- 10-15% nitrogen leakage due to temperature and internal pressure in the liquid nitrogen tank

- Nitrogen gas pressure fluctuations along with cylinder changes!

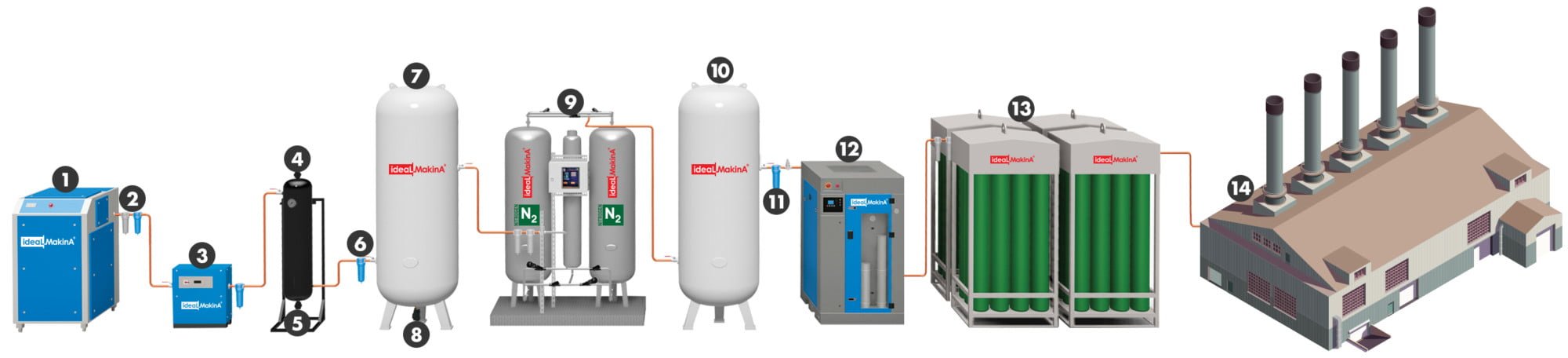

1- Screw Air Compressor

2- Water Seperator and Particle Filter

3- Compressed Air Dryer

4- Activated Carbon Tower

5- Particle Filter

6- Dust Filter

7- Air Vessel

8- Automatic Condensate Drain

9- Nitrogen Generator

10- Nitrogen Generator Buffer Vessel

11- Nitrogen Distribution Set

12- Nitrogen Booster Compressor

13- Nitrogen Bundle

14- Process

OUR SUPERIOR FEATURES

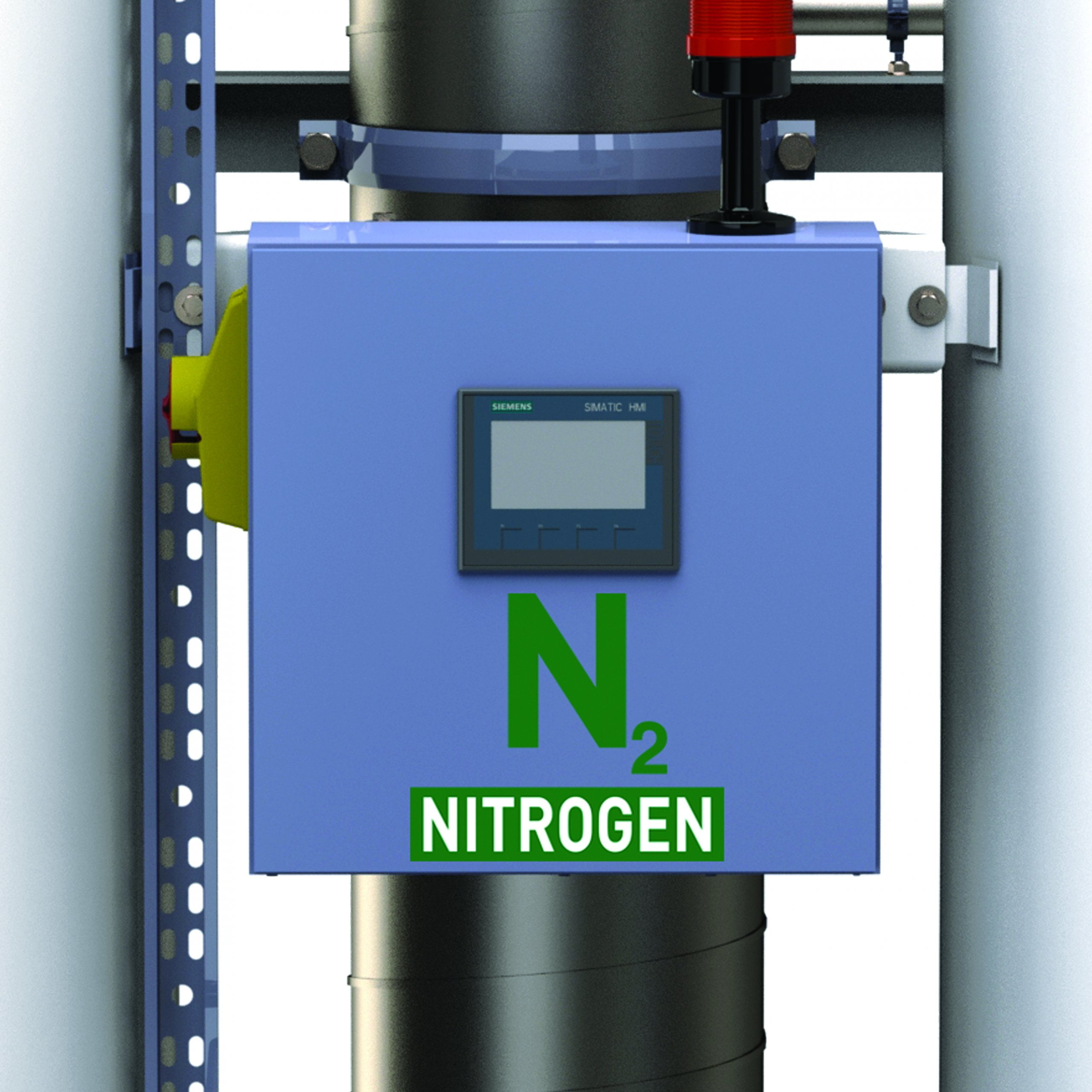

Touch Control Panel

- 5″ – 10″ Touch Color Screen

- 16 Language Options

- 14 Sensor Inputs

- Long-lasting Zirconia oxygen sensor

- Modbus/Profibus/RMB

- IP55 Protection Standards

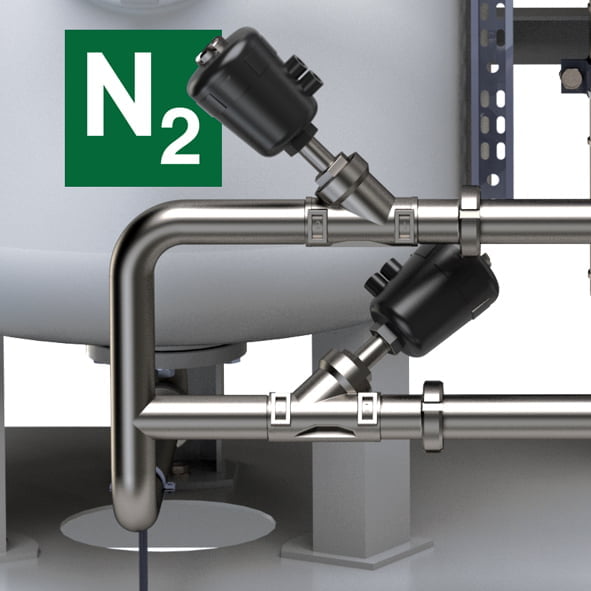

Redundant Valve Technology

- Spare Valve Set

- Continuous Production Guarantee

- Easy Maintenance

- Easy Control Function

- Leak-proof valve connection

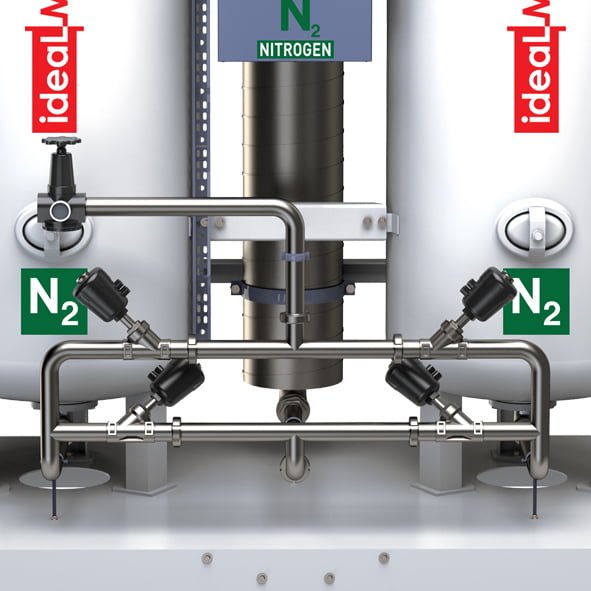

AISI 316 Block Valve Technology

- High quality stainless steel

- Pneumatic Control

- No maintenance need

- Small footprint monoblock design

Autopure Technology

- Continuous purity control

- Purity Guarantee

- Purity Control Valve

- Low purity relief valve

- Extra purity control line

24/7 Service Support

- Expert technical service

- Online Technic Service Support

- Installation and supervisor service

- Fast and effective intervention

- 10-year spare parts warranty

Low Air Factor

- Vortex technology

- The lowest air factor in the World

- Air consumption to the extent required

- Nitrogen production at high flow rate with a smaller compressor

- Low energy consumption, economical nitrogen production

Low Operation and Maintenance Costs

- Long maintenance period

- High quality equipments

- Low spare parts and service costs

- Maintenance-free exhaust and valve technology

Industry 4.0

- Modbus / Profibus / RMB / Ethernet access and remote control options

- Remote access via Android and IOS based applications thanks to GSM module.

- Single point control of system equipment such as compressor, dryer, nitrogen generator, booster and filters.

High Quality CMS

- German made CMS

- 60,000 hours / 10 years performance guarantee

- 3°C dewpoint is sufficient in compressed air, no need for chemical dryer.

- Environment friendly

REQUIRED COMPRESSED AIR FEATURES

- Temperature Range: +5 / +50˚C

- Air Quality: ISO 8573.1 Class 1.4.1

- Dew Point: +3˚C

AMBIENT CONDITIONS

- Temperature Range: +5 / +40˚C

- Optional: -50 / +60˚C

TECHNICAL FEATURES

- Max. Working Pressure: 11 bar

- Power Connection: -230V, 50Hz

- Noise Level: 55 / max 78dB(A)

ADDITIONAL ADVANTAGES

- Dew Point Sensor

- Flowmeter

- Profibus / Modbus Data Transmission

- GSM Communication

- Lan / Ethernet Connections

- RS 232 Simultaneous Ageing

- Skid Mounted Mobile System

- Container Mobile System

- Cylinder Filling Station

* Please consult IDEAL MAKINA Sales Engineers for different ambient temperatures and inlet air pressure values!

- Continues hig purity guarantee

- Low air consumption and maintenance costs

- Easy usage and maitenance

- Coloured touch screen

- Instant monitoring and recording of parameters such as purity, pressure and flow

- Remote Software Control

- Maintenance free AISI316L Stainless Steel Control Valves

- Full automatic operation without the need for an operator

- 7/24 technic support

- Plug & Play model selection

- Skid mounted mobile design

- Mobile containerized design

- Cylinder filling up to 200 bars

İdeal Makina Azot Jeneratörleri havadan azot gazı üretmek için PSA (Pressure Swing Adsorption) teknolojisini kullanmaktadır.

İdeal Makina Azot Jeneratörleri, içerisinde CMS (Carbon Molecular Sieve) bulunduran iki adet tanktan oluşmaktadır. Hava şartlandırma ekipmanlarından geçerek basınçlandırılan hava azot jeneratörü birinci tankının altından girip tank içerisindeki tüm CMS’den geçerek jeneratörün üzerinden azot stok tankına saf halde gönderiir. Bu esnada CMS tarafından tutulan oksijen, argon, karbonmonoksit ve diğer gazlar egzoz yoluyla atmosfere bırakılır. Dokunmatik kontrol panosunca set edilen zaman aralığında birinci tankın işlemi bittikten sonra, ikinci tankın altından şartlandırılmış hava girer ve tüm CMS boyunca geçip jeneratörün üzerinden azot stok tankına saf halde gönderilir. Böylece kesintisiz azot gazı üretimi CMS doldurulmuş iki tankın tandem (senkron) çalışmasıyla sağlanmış olur.