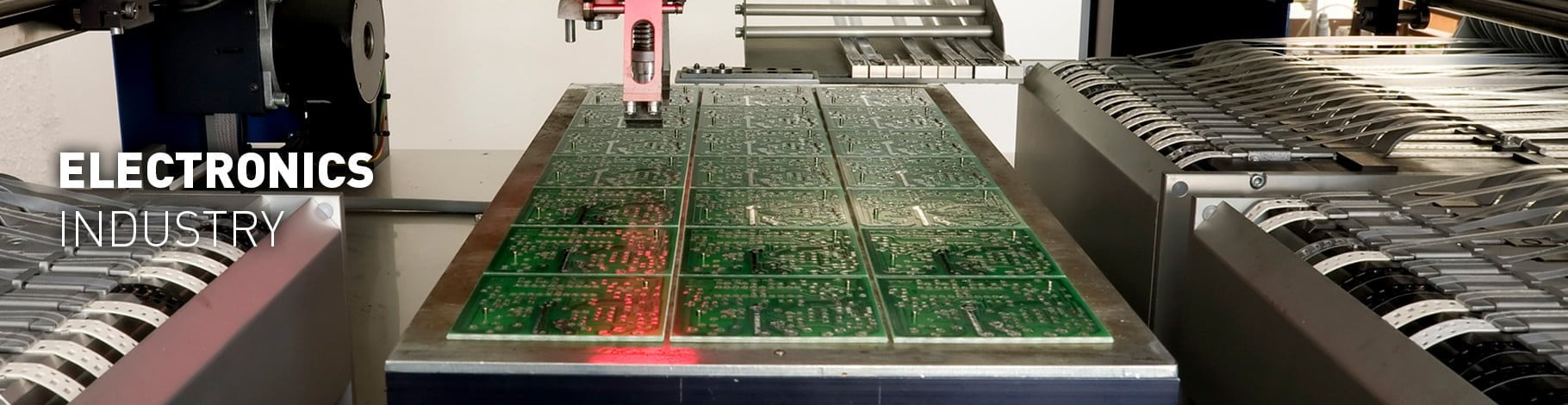

Nitrogen gas is used within the electronics and communication industry to prevent oxidation by ensuring an oxygen-free environment during the assembly of circuit cards, packaging and soldering procedures and it ensures superior quality products are obtained. Moreover, it is used in various cleaning procedures applied inside the ovens. Nitrogen gas ensures that several errors are eliminated.

Lead-free Soldering

During lead-free soldering, nitrogen gas is used to eliminate a number of errors. It is possible to prevent the oxidation layer on metal surfaces. The resistance of joint points of the solders are increased. Less clinker is accumulated on the surfaces where the procedures take place. One of the most important mistakes which causes Head-In-Pillow problem can be prevented. And together with all of these advantages, workmanship costs are reduced for production.

Soldering After Remelting

Nitrogen gas is used inside remelting ovens to reduce a number of errors. It is possible to prevent the oxidation layer on metal surfaces. Resistance of the joints on the solders are increased. Less clinker is accumulated on the surfaces where procedures take place. One of the most crucial mistakes, which is the Head-in-Pillow problem can be prevented via this method. And together with all of these advantages, workmanship costs related to production are also reduced.

Wave Soldering

Nitrogen gas is used during wave soldering to reduce the amount of clinker formed significantly. Operator spends less time on pieces that contain lead. The errors on the solder are reduced completely. As a result of all of these advantages, this equation is obtained:

Minimum Error = Minimum Costs

Protective Atmosphere During Assembly

The nitrogen gas used during assembly allows lower procedure temperatures. Moreover, it ensures that the procedures can be done

with ease and allows the creation of a wider process window.

Effective Production with İdeal Makina

İdeal Makina reduces the rate of erroneous production within solder ovens thanks to the systems that it establishes with Ideal Makina Nitrogen Generators. One of the primary errors in this sense is called Head-In-Pillow error. Highly pure nitrogen gas prevents these errors and production becomes more effective. In general, it is possible to save time, temperature and costs during production.