PRODUCE YOUR OWN OXYGEN GAS, FORGET YOUR CYLINDER OR LIQUID OXYGEN PURCHASING COSTS!

IDEAL MAKINA PSA Oxygen Generator Systems produce oxygen in the form of gas from compressed air on-site where they are running and offer a cost-effective, continuous and safe solution compared to traditional oxygen gas sources such as cylinders or cryogenic liquid. Our Oxygen Generators; available in 21 standard models with a capacity of 95% purity ranging from 0.5 to 2000 Nm3 / h. The design is made for 24/7 operation. Each oxygen generator is equipped with an automatic start and stop function, which allows the user to start and stop automatically according to oxygen consumption.

WHY IDEAL MAKINA OXYGEN GENERATORS?

- Continues high purity guarantee

- Low air consumption and maintenance costs

- Easy usage and maitenance

- Coloured touch screen

- Instant monitoring and recording of parameters such as purity, pressure and flow

- Remote Software Control

- Maintenance free AISI316L Stainless Steel Control Valves

- Full automatic operation without the need for an operator

- 7/24 technic support

- Plug & Play model selection

- Skid mounted mobile design

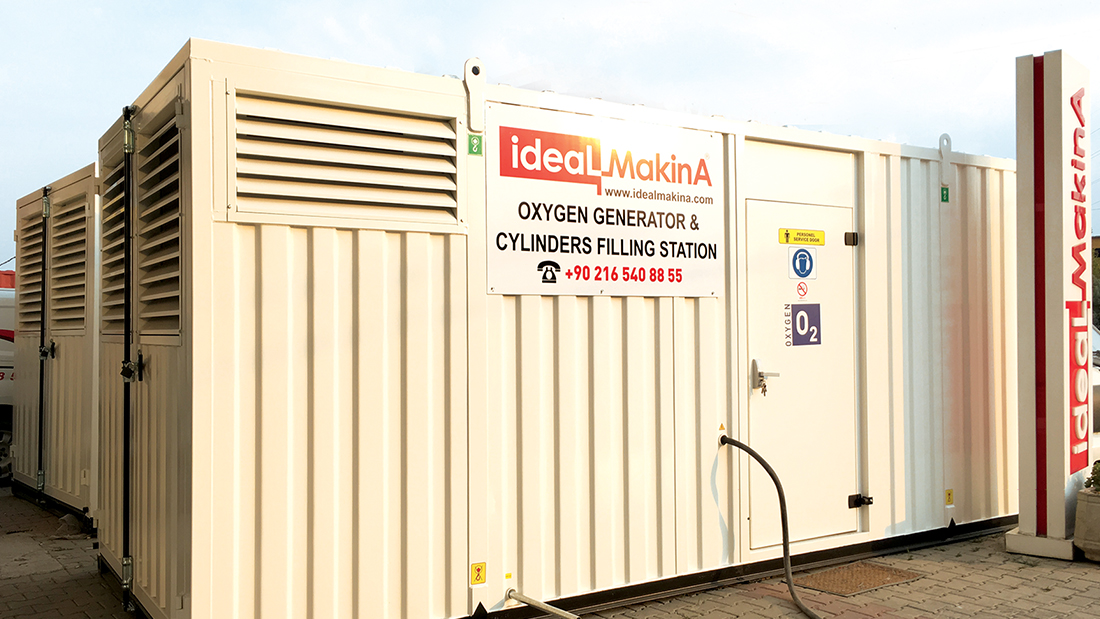

- Mobile containerized design

- Cylinder filling up to 150 bars

- Uninterrupted Production Guarantee with Redundant Valve System

You do not only buy oxygen cylinder or liquid oxygen, but you do also buy:

- Safety problems due to high pressure in the cylinders

- Cylinder / liquid oxygen tank rental

- Transportation costs

- Internal purchase expenses

- Labor costs and risks for cylinder when loading – unloading and transportation.

- 10-15% oxygen leakage due to temperature and internal pressure in the liquid oxygen tank

- Oxygen gas pressure fluctuations along with tube changes

The Solution: IDEAL MAKINA Oxygen Generator Systems

- In the amount you need

- 95% purity (99,5% purity with UHP Series)

- At requested pressure

- Under your control

- It is in your hands to produce oxygen gas at a much lower cost

We know very well what you expect from an Oxygen Generator!

- Continues High Purity

- High quality but economical

- High technology but easy to use

- Long life but trouble free

- Technical service but 7/24

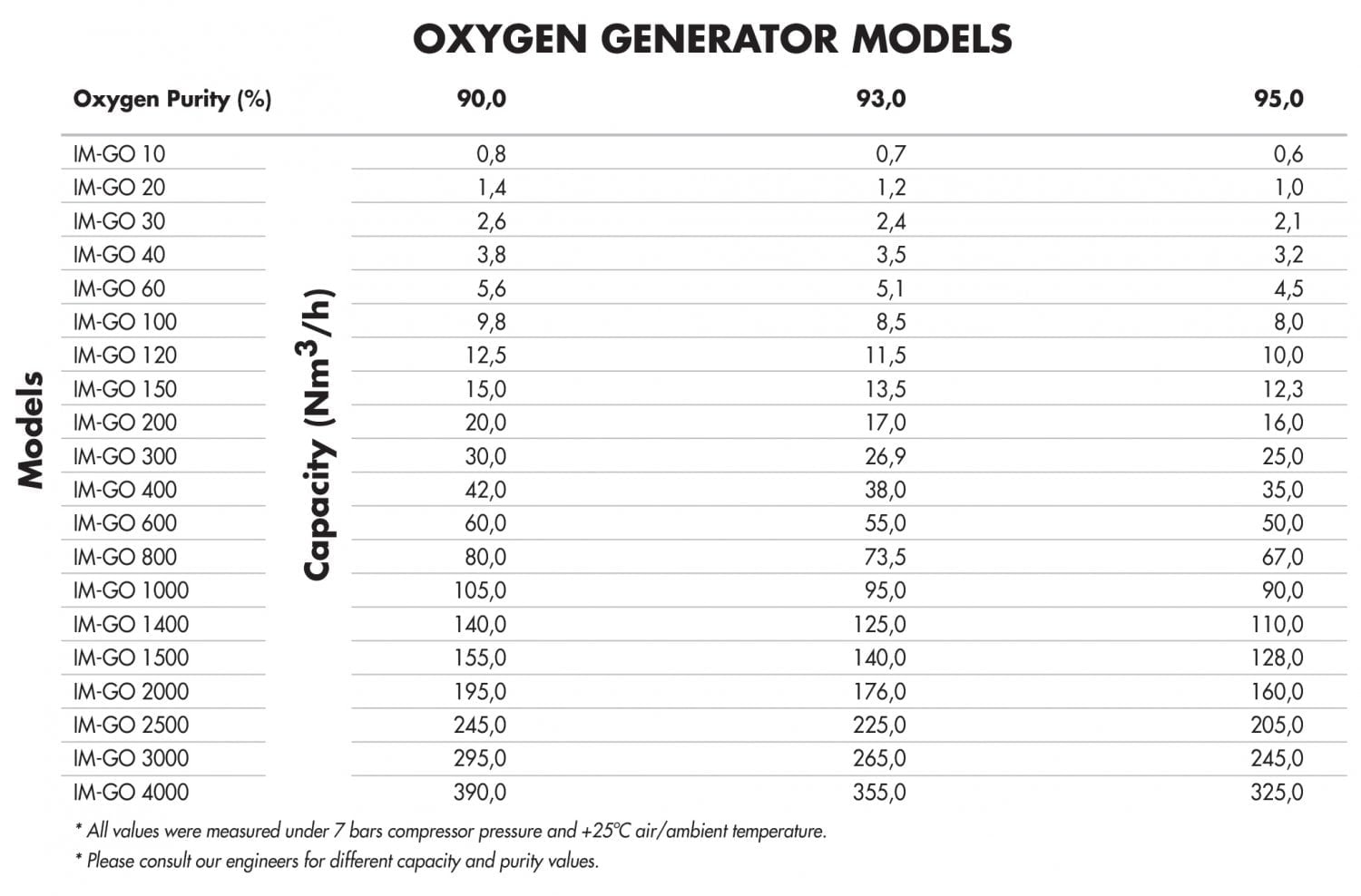

Through the PSA technology used by IDEAL MAKINA OXYGEN GENERATOR SYSTEMS, you can produce oxygen gas in the range of 90% – 99.5% purity in the capacity range of 0.5 – 2,000 Nm3/h…

95 % Ideal Makina Oxygen Generators

- Capacity : 0,5 – 2000 Nm3/h

- Purity : 95%

- Pressure : 1- 150 barg

- Technology : PSA (Pressure Swing Adsorption)

- Manufacturing Area : Turkey

99,5% UHP Ideal Makina Oxygen Generators

- Capacity : 0,5 – 1700 Nm3/h

- Purity : 99,5%

- Pressure : 1- 150 barg

- Technology : DIA (Developed Ideal Adsorption)

- Manufacturing Area : Turkey

We are ready to serve you with our combination of superior Oxygen Generator and İDEAL MAKİNA project and application experience. Contact us! 0216 540 88 55

Be our customer like in our Reference List. Purchase solutions, not problems!

REQUIRED COMPRESSED AIR FEATURES

- Temperature Range: +10 / +50˚C

- Air Quality: ISO 8573.1 Class 1.4.1

- Dew Point: +3˚C

AMBIENT CONDITIONS

- Temperature Range: +5 / +40˚C

- Optional: -50 / +60˚C

TECHNICAL FEATURES

- Max. Working Pressure: 10 bar

- Power Connection: 230V, 50Hz/60Hz

- Noise Level: 55 / max 85dB(A)

ADDITIONAL ADVANTAGES

- Dew Point Sensor

- Flowmeter

- Profibus / Modbus Data Transmission

- GSM Communication

- Lan / Ethernet Connections

- RS 232 Simultaneous Ageing

- Skid Mounted Mobile System

- Container Mobile System

- Cylinder Filling Station

* Please consult IDEAL MAKINA Sales Engineers for different ambient temperatures and inlet air pressure values!

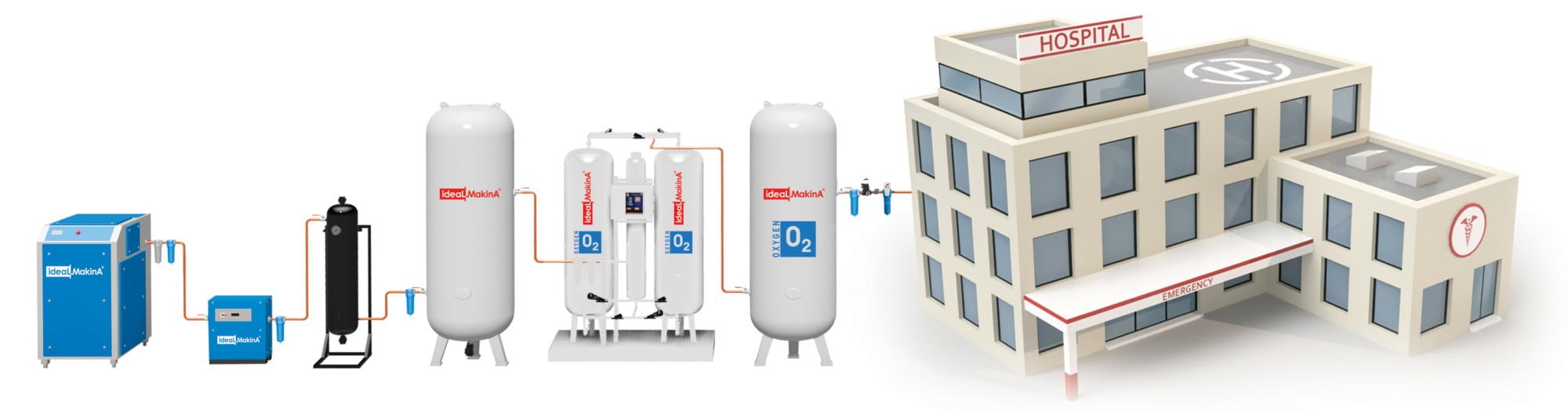

Ideal Makina Oxygen Generators use PSA (Pressure Swing Adsorption) technology to produce oxygen gas from the air.

Ideal Makina Oxygen Generators consist of two tanks containing ZEOLITE. The air; which is pressurized by passing through the air conditioning equipments, enters from the bottom side of the first tank and passes through the entire ZEOLITE inside the tank and transmits it to the oxygen stock tank in high purity.Meanwhile nitrogen, argon, carbon monoxide and other gases trapped by ZEOLITE are released to the atmosphere through exhaust. After the operation of the first tank is completed within the time interval set by the touch control panel, conditioned air enters the bottom of the second tank and passes through the ZEOLITE and is being sent to the oxygen storage tank in pure form. Thus, continues oxygen gas production is achieved by tandem (synchronous) operation of two tanks filled with ZEOLITE.