This is a multistage, air cooled high pressure piston type air and gas compressor. It is used for compressing and storing air, nitrogen, helium, argon and gas mixtures between 0 and 5 barg. Ideal Compressor High Pressure Gas Compressors are used to fill the cylinders with gas up to 310 barg pressure provided that gas is fed to the suction inlet at 0 – 5 barg pressure. The desired filling pressure can be adjusted between 100 barg and 310 barg. When the desired upper pressure is reached, the compressor stops automatically and goes into standby mode. In these compressors, a special system is used in the gas supply line with nitrogen. Critical values like the absorbed nitrogen gas pressure, flow rate, tightness, stabilization of the pressure value, etc. are kept under constant control and periodic maintenance to be performed once in 2000 operating hours ensures trouble-free operation of the compressor for many years.

- Outlet capacity range: 12 – 60 Nm3/h @230 barg

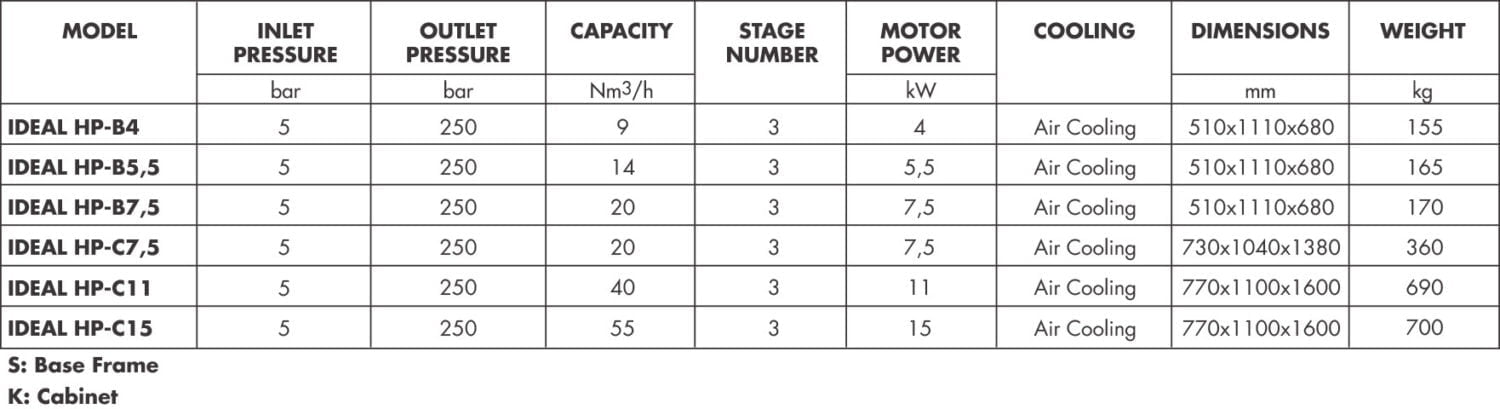

- Power of Motors: 5,5 – 15kW – IE3 Motors

- Max. Outlet Pressure: 310 barg

- Special Oil Vapor Absorber P61 Purifier and Refillable Cartridge (Stainless Steel)

- High Pressure Particle and Oil Trap Filter (Stainless Steel)

- Quiet and Low Vibration Operation Through Sound Insulation Cabinet

- Reliable Belt Pulley Drive System

- High Production Quality – Low Maintenance Expenses

- User Friendly Control Panel with Electronic PLC

- Oil Temperature and Pressure Control

- Automatic Start / Stop

- Special Nitrogen Suction System

- Vibration Free Long Life Intercoolers

- Automatic Drainage System

- Nitrogen Generators for Laser Cutting Machines

- Gas Cylinders Filling Stations

- Breathing Air Cylinder Filling

- Plastic Injection

- Companies with Sudden Peak Gas Consumption