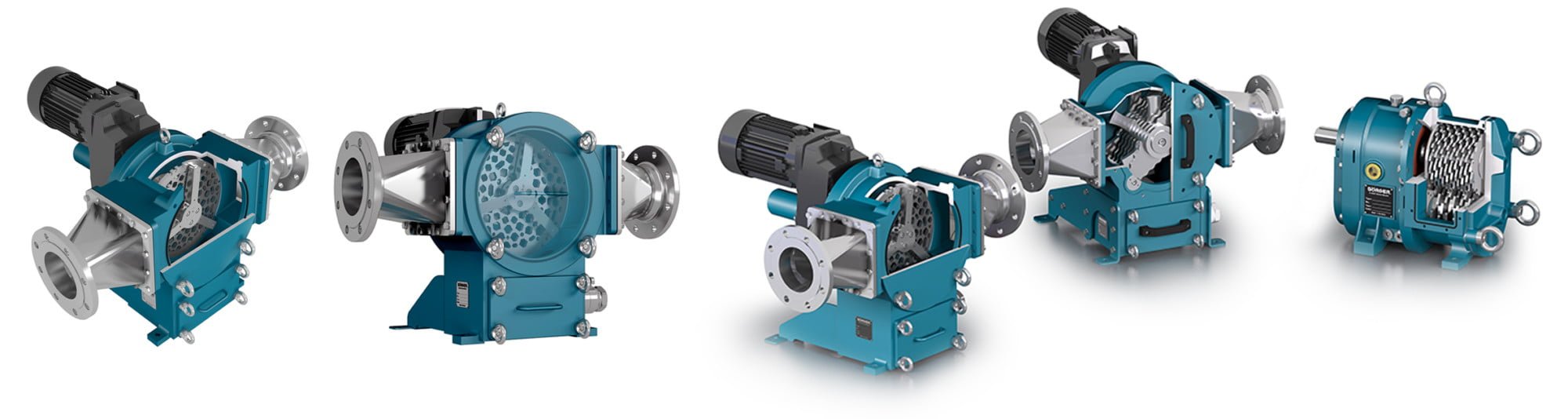

Börger Multichopper, giriş tarafındaki delikli bir disk ve hareketli bıçaklar sayesinde sıvı içindeki katıların parçalanmasını sağlar. Parçalama performansını disk tasarımı, dönüş hızı ve akış hızı belirler.

The Börger Multichopper is a chopping unit with perforated disk and rotating blades on the inlet side for chopping solids contained in the liquid. The design of the perforated disk, the flow rate and the speed mainly determine the chopping result.

- Heavy-duty, robust casing in solid engineering

- Robust carrier gear unit with solid intermediate plate and hollow shaft

- Mechanical seal with quench reservoir that has been tried and tested over decades

- Reversible perforated disk, can be used on both sides, directly connected with the drive unit

- Multi-vane rotating blade unit with precision adjustment to the perforated disk

- External axial blade adjustment, with MCA on request

- Large outlet hole, easy-to-use quick-release cover

The Börger Multichopper is a chopping unit with perforated disks and a rotating tri-blade on the inlet side for solids contained in the liquid. The arrangement of the perforated disk, the throughput volume and the speed is mainly determined by the chopping result required.

Using a pump or any other suitable inlet pressure, the medium is drawn through the openings of the perforated disk of the Multichopper. The rotating blades on the perforated disk perform many cuts per rotation. This achieves a reliable and smooth process for chopping coarse material. A centrally external adjusting screw can be used to regulate the pressure of the rotating blade to the perforated disk.

Reversible flow rate

Multichopper iki modeli mevcuttur.

Multichopper püre; saklanan akışkan içinde partiküllerde hemen hemen hiç yer kalmayacak şekilde tasarlanmıştır. Multichopper plus ise bir enkaz toplayıcı ile donatılmıştır.

Her iki modelde 220 m3/h lik hacime kadar farklı büyüklüklerde mevcuttur.

Various perforated disks are available, depending on the chopping result required. The flow rate depends on the medium and the solids which need to be chopped. The hardened cutting steel ensures optimum service life. The perforated disk is built to last with its reversible use and many cuts per rotation are guaranteed with the multi-vane blade holder.

KNIFE TYPE:

Using a pump or any other suitable inlet pressure, the medium is drawn through the openings of the perforated disk of the Multichopper, which are set to suit the medium. The rotating blades on the perforated disk perform many cuts per rotation. This achieves a reliable and smooth process for chopping coarse material. A central, external adjusting screw can be used to regulate the pressure of the rotating blade to the perforated disk.

- Long service life

- Ease of maintenance thanks to MIP

- Low life-cycle costs

- Blade adjustment with sophisticated external control (= easy to control from outside), readjusted in closed, filled system through careful manual movement

- Reliable, powerful, robust

- Compact, low-on-space design

- High degree of chopping

- With MCA on request

- High level of safety thanks to quench chamber

- Inline design

- Robust carrier gear unit

- External MCA blade adjustment

- Reversible perforated disks and blades

- Different perforated disks can be selected – for variable chopping results

- On request with highly advanced control technology ‘made by Börger’

The ATEX Directive 94/9/EC defines the prescribed technical requirements for equipment and protective systems intended for use in potentially explosive atmospheres in Europe.

All Boerger Multichoppers can be used in potentially explosive atmospheres in accordance with the ATEX Directive.

Working hours shouldn’t be wasted on maintenance! This was the basic principle which drove us to develop a highly efficient and above all reliable rotary lobe pump and chopping unit. Because unnecessary repair work and downtime cost time and money. We strive to give our customers the chance to increase their own productivity using our products.

The Boerger Multichopper is extremely efficient with less energy consumption compared to conventional systems due to its long service life, very low cost of spare parts and unbeatable ease of maintenance.