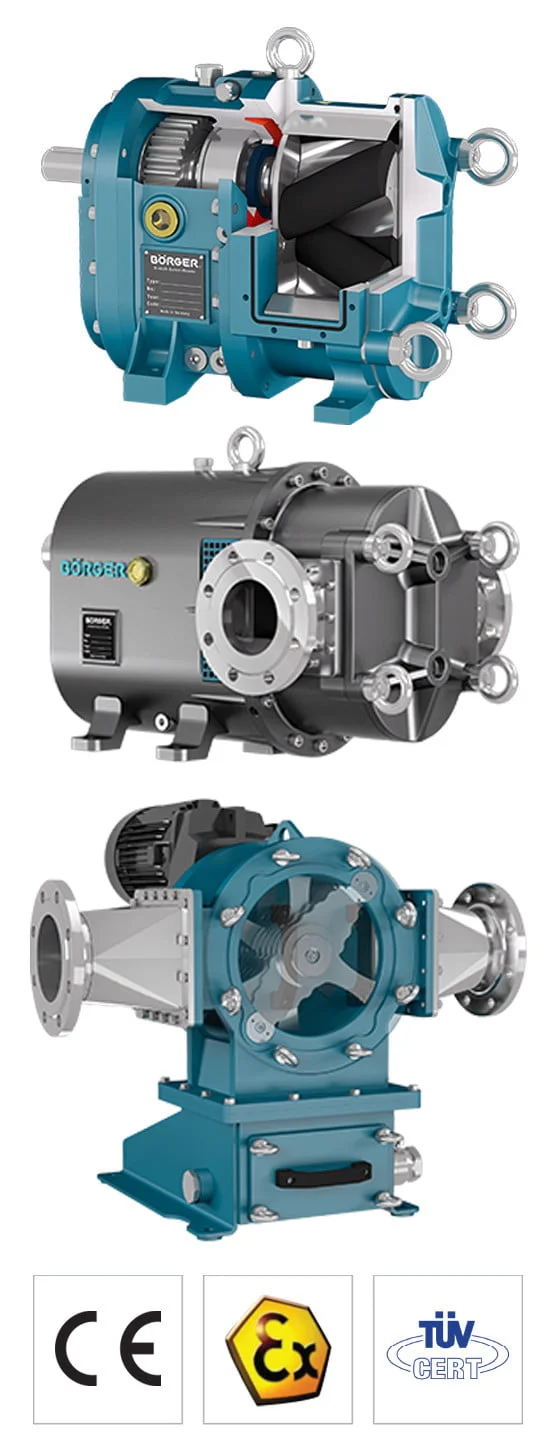

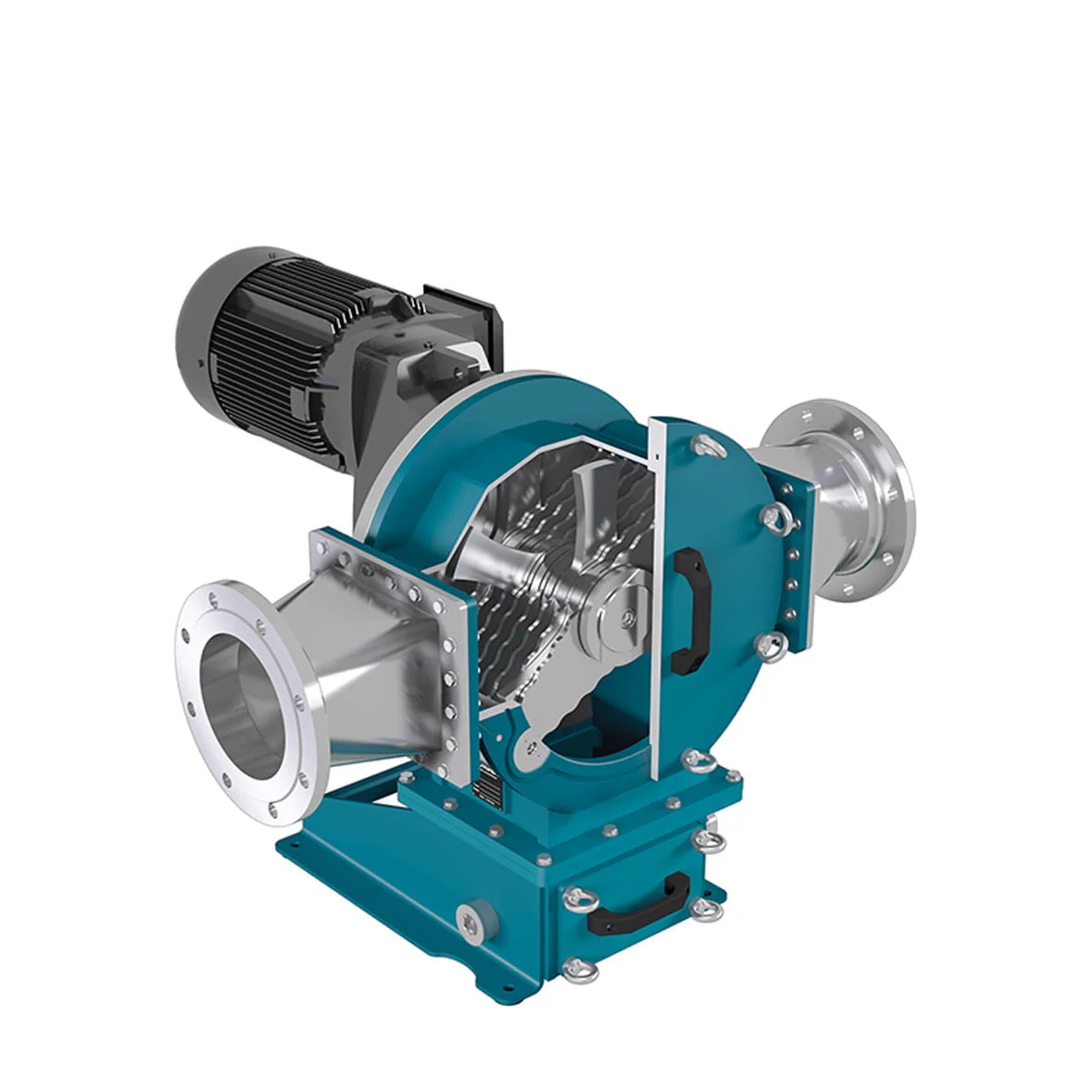

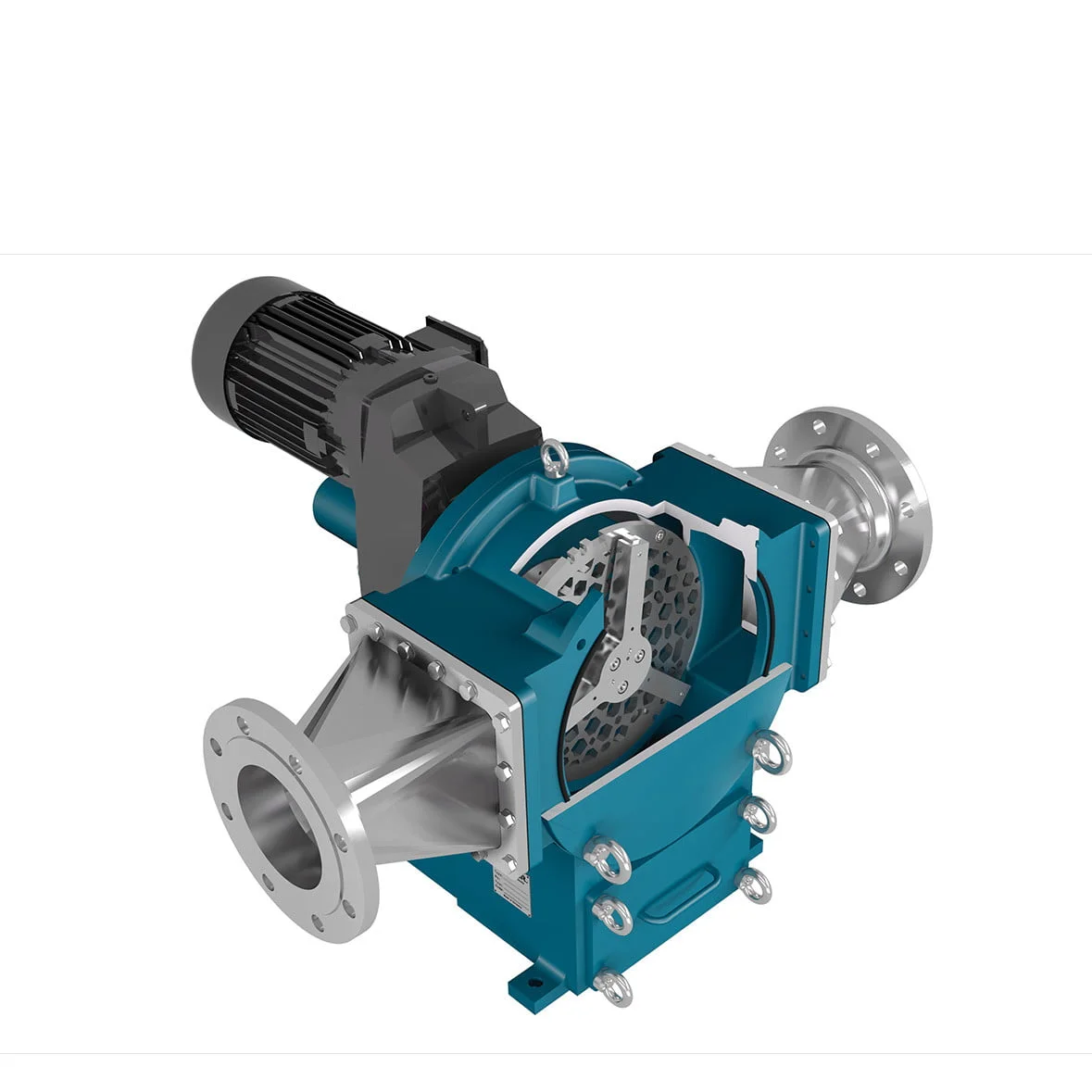

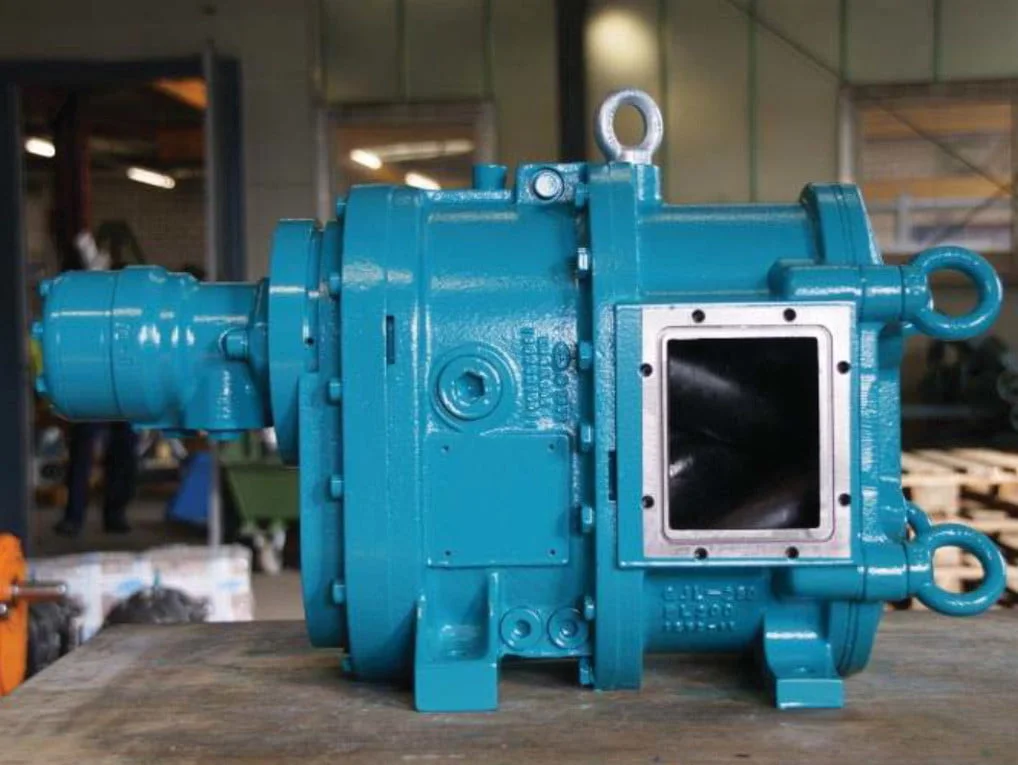

With a wide range of 24 pump sizes (rated capacity up to 1600 m³/h) a large selection of equipment and additional parts, Börger is able to build rotary lobe pumps which are perfectly suited to every single application.

The large-scale geometry and short passage enable the medium to be pumped efficiently. Our three product lines, Classic, Select and Protect, offer an appropriate shaft seal for each application.

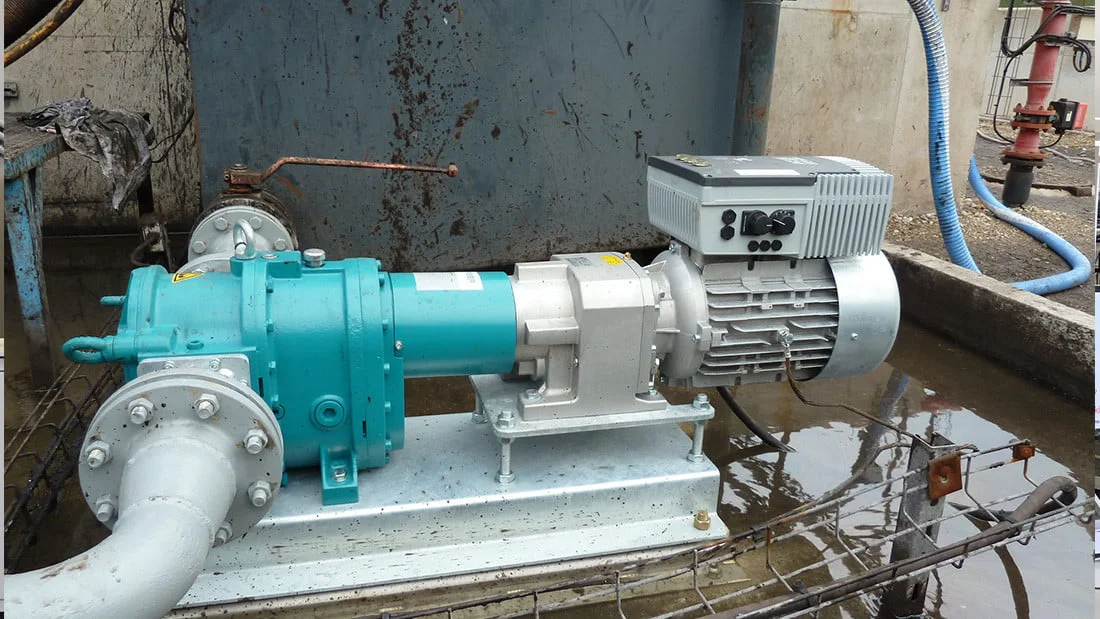

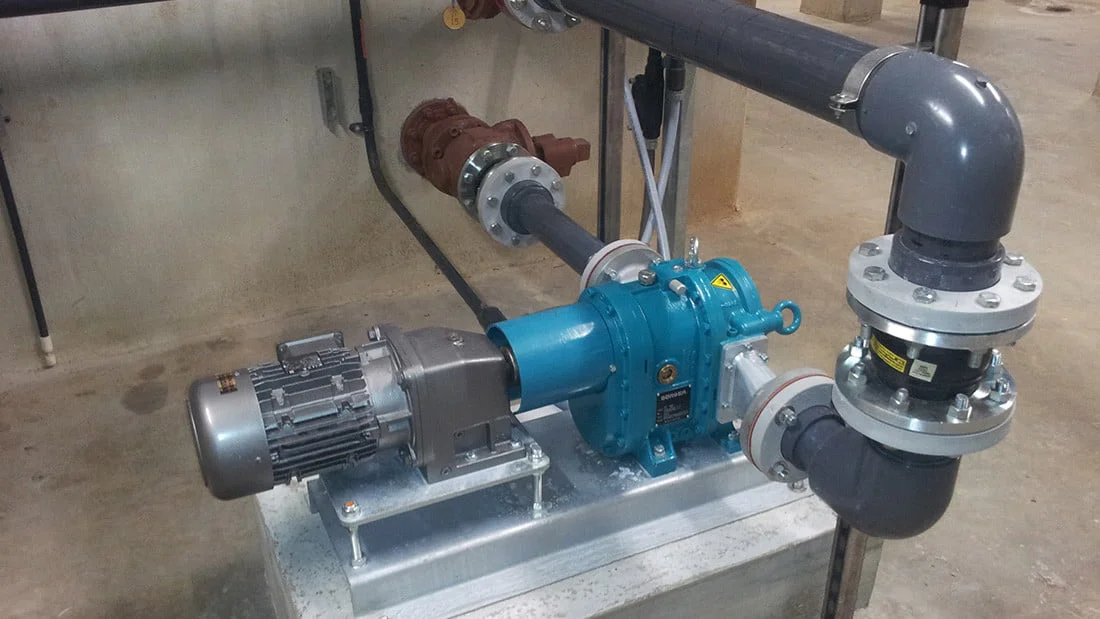

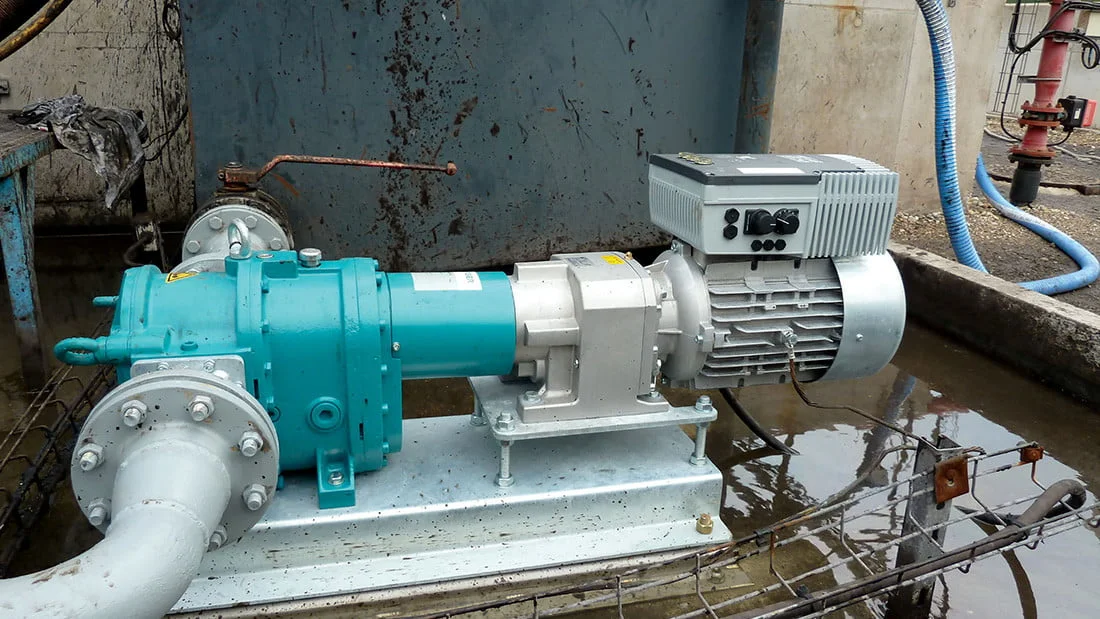

This is because each Börger pump is a customized solution. Börger is unrivaled in its selection and variety of material. But the pump is also completely designed to meet the specific requirements of the application. Whether it is with mounted drive, as a submersible model or as a mobile pump on a tanker truck, the Boerger Rotary Lobe Pump is as unique as your requirements.

TECHNICAL FEATURES:

- Capacity Range : 1 – 1600 m3 / h

- Suction Capability : max. 8 mss

- Pressure: max 16 bar

- Operating Temperature: From 0°C to 200 °C

- Short-Term Dry Running Up To 30 Minute

- Lobe and Shaft Seal Options For Different Processes

- Compact Design

- Reversible Direction Of Rotation

- Easy and Economical Maintenance

MOTOR TYPE

ELECTRIC MOTOR

COMBUSTION MOTOR

HYDRAULIC MOTOR (ADAPTER LANTERN)

HYDRAULIC MOTOR (HOLLOW SHAFT)

PTO

COMPRESSED AIR

Börger mobile pumps are tailored to the customer’s specific needs. From the trailer to the pump technology, to the control panel technology, Börger makes everything, in line with the customers’ wishes.

Börger Rotary Lobe Pumps are self-priming , valveless, positive displacement pumps. The even rotation of the rotor pair creates a vacuum on the priming side of the pump, which can be defined by the direction of rotation of the drive. This vacuum draws the liquid into the pump chamber. With further rotation, the pumped medium is conveyed past the pump wall into the pressure area. Up to six chamber charges are displaced with each drive rotation– depending on the rotor type. When the rotor is at a standstill, the pump seals off almost completely.

- Rotary Lobe Pump As Cellular Wheel Sluice

- Bentonite

- Photo Chemicals

- Fiber Cement

- Vegetable Solids

- Bone Particles

- Titandioxide Suspension