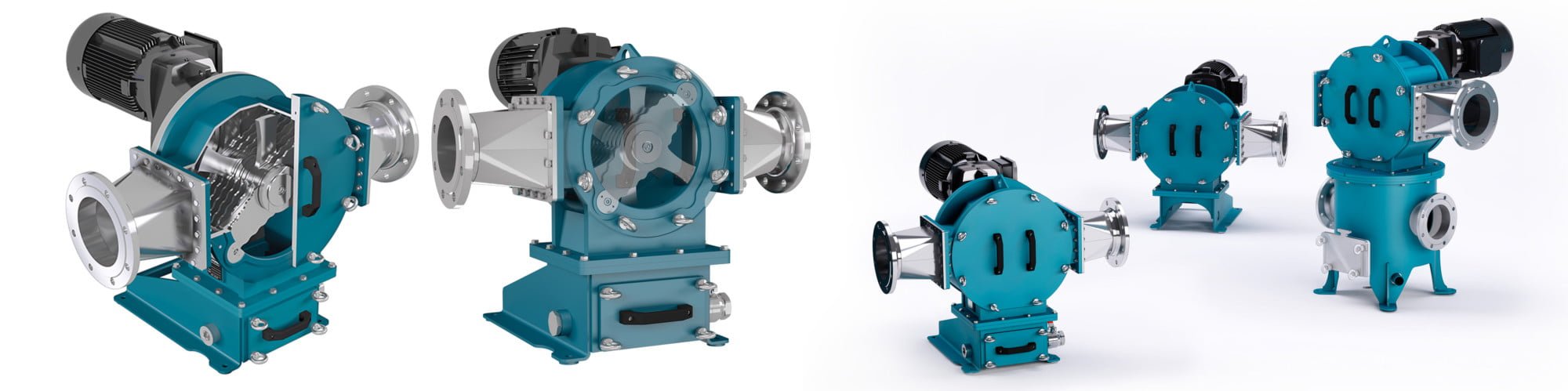

The Rotorrake is a robust, single-shaft coarse macerator as an inline version. Blades and counter blades are mounted one after the other with a spacer on the carrier shaft. The cutting and wiping edges of the sturdily attached counter blades are each cleaned by the rotating cutting blades. The blades are moved by the rotating shaft.

The Rotorrake comes in different sizes (flow rates of up to 800 m³/h) and tackles macerating tasks where others have failed – for macerating very coarse solids and ‘entanglements’.

The Rotorrake is a robust, single-shaft coarse macerator as an inline version.

Blades and counter blades are mounted one after the other with a spacer on the carrier shaft. The cutting and wiping edges of the sturdily attached counter blades are each cleaned by the rotating cutting blades. The blades are moved by the rotating shaft.

The Rotorrake comes in different sizes (flow rates of up to 800 m³/h) and tackles macerating tasks where others have failed – for macerating very coarse solids and ‘entanglements’.

- Single-shaft macerator

- Different sizes

- Debris collector

- Low on wear – no-contact arrangement of blades and counter blades

- Excellent extraction of hard substance

- Powerful macerating force

- Flow rate of up to 800 m³/h (13,300 l/min)

The liquid fed in with the solids flows through the stationary counter blades which are arranged at an angle. The solids are then captured by the counter blades and shredded by the cutting action of the rotating blades. At a low flow speed, the solids are shredded multiple times by the rapidly rotating blades. The shredded solids then continue to flow with the liquid. Coarse objects which cannot be shredded are ejected into the debris collector.

Rotorrake has a modular design and can be used in reverse mode for different shredding jobs.

Drive Types:

- Paralel shaft helical drive motor,

- Hydraulic motor,

- Bearing assembly with bare drive shaft.