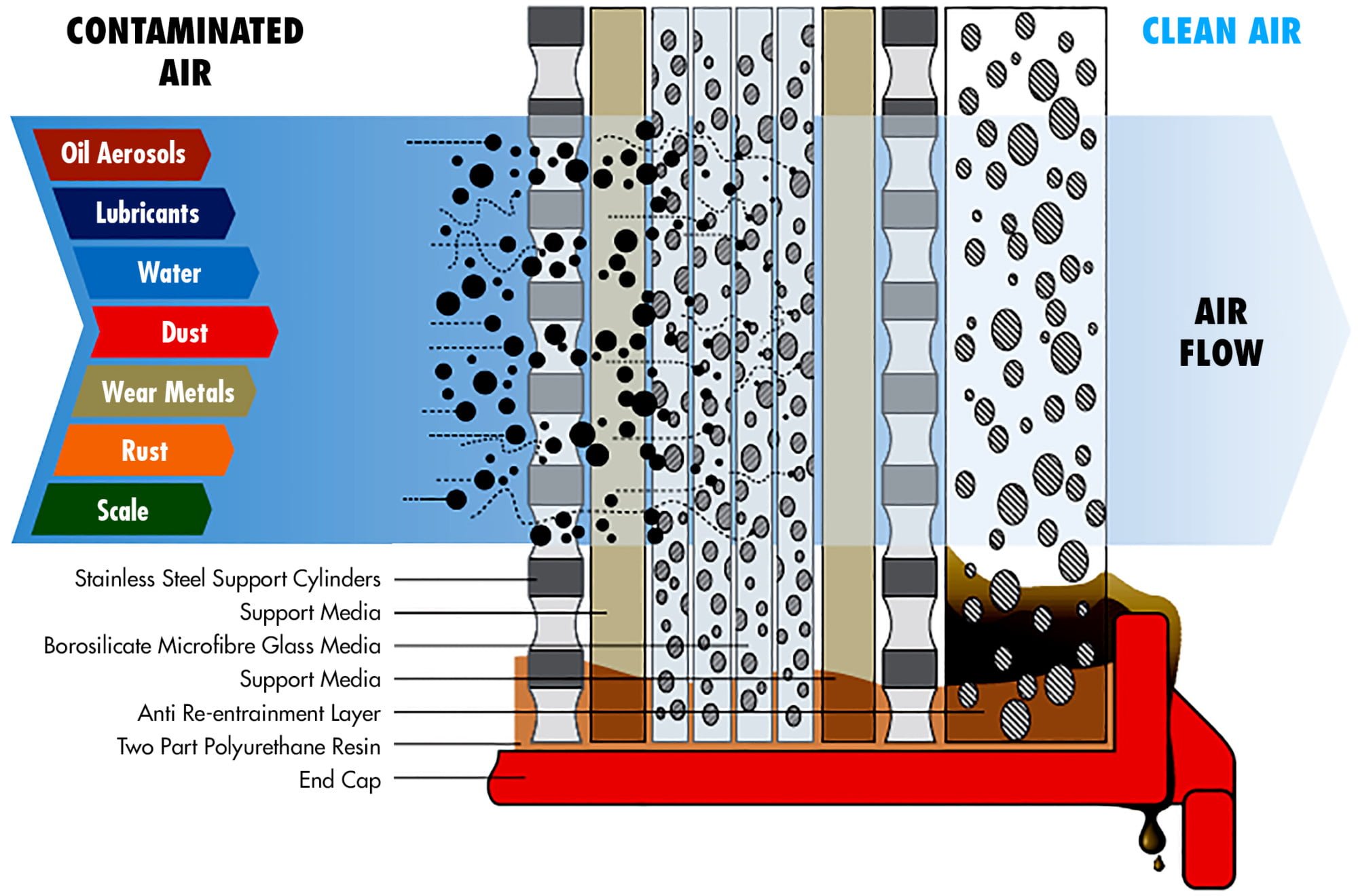

There are some undesired contaminations in the compressed air produced by the compressors. These contaminations are; particles, water, oil and oil aerosols. These unwanted contaminations must be removed from the system in order to prevent damage to the air powered machines and to damage the products that air touches. For this, water separators, compressed air filters, activated carbon towers and water-oil separators are used. Depending on the internal structure of the filter cartridge, the particle size, oil and water amounts retained.

Correct selection of filters and maintenance follow-up is very important. Incorrect selection and timely maintenance cause pressure losses and consequently energy losses.

OMEGA Filters: Filters that separate particles, water and oil aerosols are generally grouped according to the pressure class they are used in and according to their filtering sensitivity. According to the pressure class; AF series preferred for applications up to 16 bar pressure, HF series used for applications up to 50 bar pressure and CHP series for applications up to 420 bar pressure safely cleans your compressed air line. According to the filtering sensitivity; The inlet filter used for particles of 1 µm and larger is divided into 3 groups, usually a precision filter holding particles of 0.01 µm and larger, and an activated carbon filter holding oil vapor up to 0.005 mg / m3, and there are different sensitivity options.

OMEGA Aktivated Carbon Tower: They are used to separate oil from pressurized air up to 0.003 mg / m3 in sensitive processes such as Electronics, Food, Laser Cutting, Pharmaceuticals and Chemistry, especially where oil vapor is not desired. It also protects your process from oil by acting as a safety valve in case of sudden separator explosion that may occur in the compressed air compressor.

OMEGA Water Seperators: The centrifugal technology it contains drains the water in liquid form in the air produced by the compressed air compressors to a large extent. In this way, equipment such as precision filters, air dryers and gas generators on the line that are used after the water separator are provided to perform more efficiently.

OMEGA Water and Oil Seperators: When separating water, oil and other contaminants from compressed air lines, we need to check where these wastes go. After the oily condensate is passed through water and oil separator, it is cleaned and brought back to nature.

Call us for the most suitable filter and element selection for your process.