High Efficiency, Long Life, Reliable…

Optimum series compressors are produced in order to work with maximum performance in different application areas. It has an ergonomic design designed with a design that requires minimum working space.

IDEAL COMPRESSORS, Optimum Series screw air compressors are designed to meet the compressed air needs of medium and large enterprises.

Optimum Series compressors, which are strong, compact, easy to install and maintain, designed entirely on high efficiency, quality and durability, each part of which is manufactured and assembled within the framework of international quality standards, ensure that the processes of the enterprises continue without interruption even in the most difficult conditions with their durable designs.

ATLAS COPCO ES4000 Advanced Control Panel

Now your compressors and dryers offer you better monitoring. The new ES4000 Advanced is equipped with graphics that monitor and report on-screen operating values. Helps you see how your compressor works in a structured time frame.

ATLAS COPCO Latest Technology Screw Element

• Licensed asymmetrical element profile and innovatively designed bearings introduce low abrasion and high reliability. • By means of the perfect performance of the screw element energy consumption is reduced by % 5-6 • Efficient air-oil seperation. • Reduction of pressure drops and energy costs. • Low oil consumption leads to minimum maintenance costs, and a long lifetime. • Simple installment, simple use and serviceIt guarantees continous optimized pressure by maintaining a high level of energy saving. • Simple, no maintenance needed installment with less moving parts. • Air-water seperator (standard) • The final cooler with the air-water seperator integrated separates the condensation efficiently and provides high-quality compressed air. • TEFPC IP55 Motor (Class F Isolation B) ensures protection against dust and chemicals. • Stable and longtime operating even in harsh working conditions where the temperature is up to 40°C (104°F)

Standart Features

• High efficiency screw block • 380-400V / 50Hz / 3Ph, IP55, IE3 main motor • Direct link drive system • Star-delta connection motor drive system • Monoblock acoustic canopy and hard base frame • Three-stage air / oil separator and tank providing mg 3 mg / m3 oil density • Dry type air intake filter with 3 micron resolution • Electropneumatic load-empty controlled suction valve • PLC control unit • Plate & bar type combi radiator • Factory filled oil with 4000 hours working life • Integrated water separator

Optionel Features

• Water cooling system • -40°C cold start option • Food grade oil • IE3 energy class main engine • Power network options other than 380V / 3Faz / 50Hz • Heat recovery with air + water cooling system

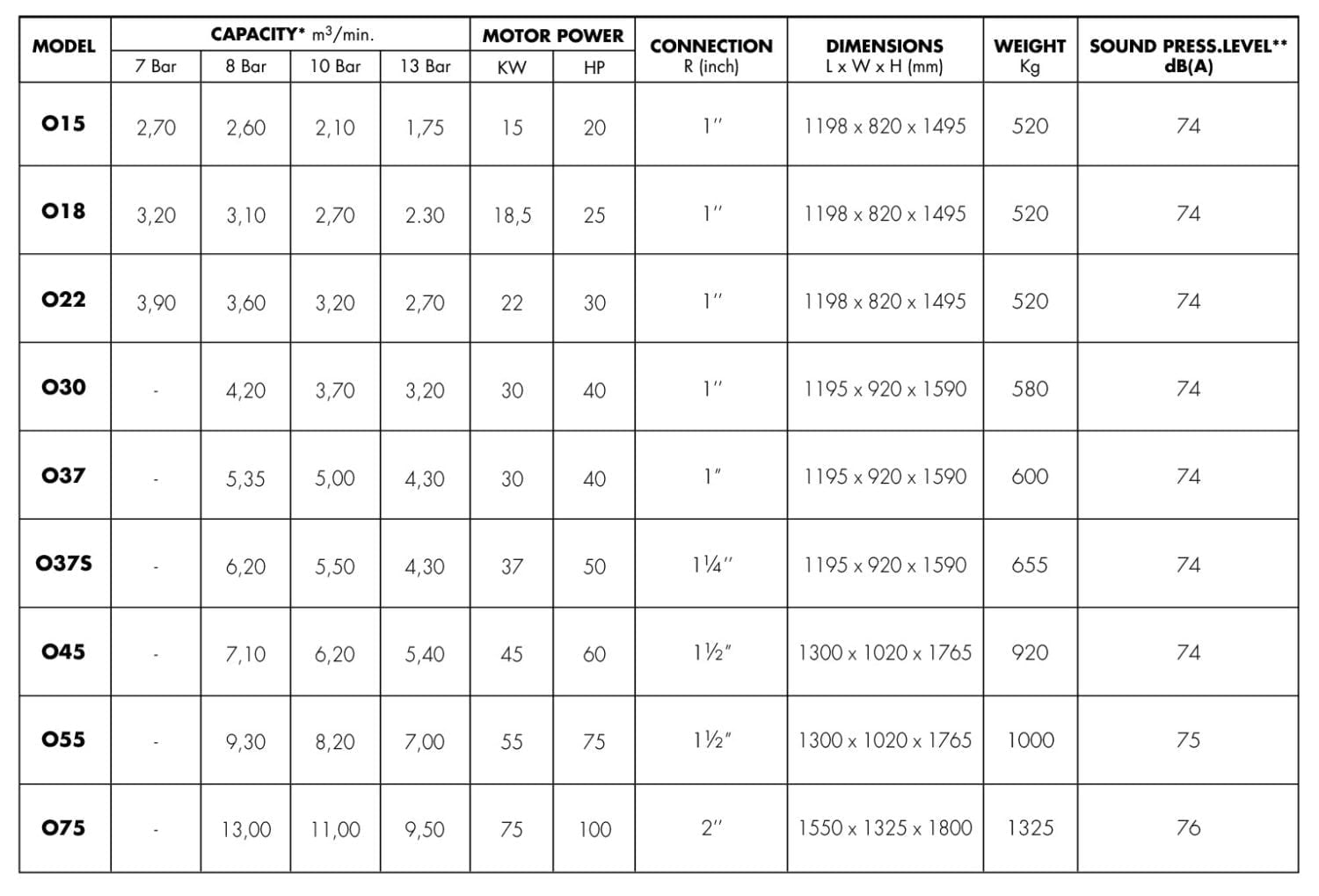

* Refers free air delivery measured according to ISO1217:2009, Annex.C

Values are recorded in reference conditions which are 1 bar absolute pressure, 0% relative humidity, 20°C air inlet.

** Refers to sound pressure level measured according to ISO2151:2004 and ISO 9614/2 with ±3 dB(A) tolerance.

IDEAL COMPRESSORS reserves its rights to make changes in its products and specifications without prior notice.

*** O15 – O18 – O22 models are being produced with AERZENER VMX22r air end, O30 – O37 – O37S – O45 – O55 – O75 – models are being produced with ATLAS COPCO air end.

Belt / Pulley Drive System, Fixed Speed / 15-75 kW

- ATLAS COPCO Screw Group

- ABB Electric And Fan Motor

- SIEMENS Switchgear Material

- OPTIBELT POLY-V Belt

- Immersion Type Mann Hummel Seperator

- Mann Hummel Filter Group

- Electronic Control Panel

- Ease of Service and Low Service Cost

- Quiet Operation with Acoustic Cabinet

- Design Suitable for Working 7/24

- Fully Equipped Safety System

- VMC Suction, MBV and Thermostatic Valve