Industry and trade need safe solutions: Therefore, BOGE piston compressors are engineered to provide dependable compressed air for a wide range of applications. A sophisticated design and uncompromising high quality workmanship ensures that BOGE piston compressors are without a doubt setting the standard when it comes to reliability and efficiency in operation.

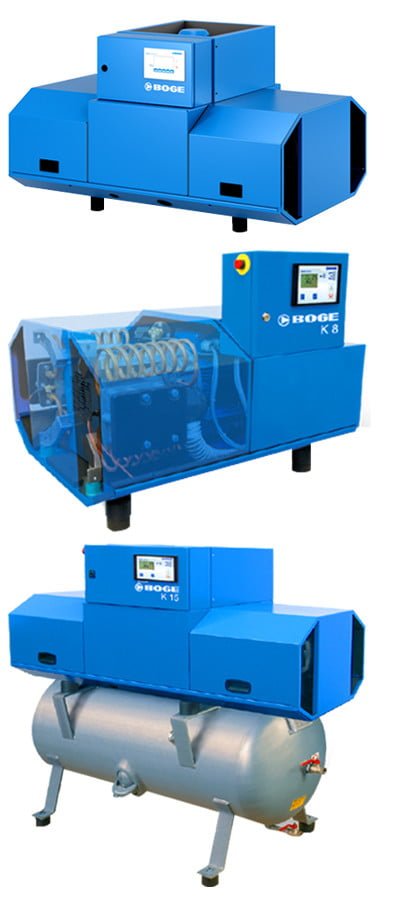

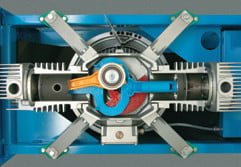

The innovation boost for oil free compressed air: The BOGE K series has been developed utilising the unique push rod system ensuring the absolutely efficient generation of oil free compressed air with extremely low wear and all in a compact design. The BOGE K series is the ideal solution for fluctuating compressed air demand regardless of whether used as a basic load or peak load machine in industry sectors that demand oil free air.

This is how compact and cost efficient oil free compressed air can be: The K series piston compressors have been developed utilising the innovative push rod principle providing absolutely oil-free compression – in an entirely new compact design. The K series has been specifically designed for the smaller compressed air user requiring 100% oil-free compressed air. And, available at an unbeatable cost effective price/performance ratio!

PROGRESSIVE

BOGE piston compressors have been engineered using the latest technological advancements. As an example, the innovative K series compressors utilise the push rod principle that enables completely oil free compressed air generation. Opting for a BOGE piston compressor means always keeping one step ahead of your competitors with safety and efficiency as standard.

RELIABLE

BOGE piston compressors are the reliable backbone of your compressed air supply – for both trade or industrial use. They have stood the test of time for more than 80 years throughout industry: robust, low maintenance and incomparably powerful.

DURABLE

Only top quality materials and the latest technology are used when designing and manufacturing BOGE piston compressors. Precisely manufactured to the smallest tolerances on modern CNC machines BOGE piston compressors are subject to extensive quality control before leaving production. This is why BOGE piston compressors are durable and robust.

FLEXIBLE

Thanks to the modular design principle, BOGE piston compressors can be easily upgraded. You decide for yourself – an oil-free or oil-lubricated system, a small, medium or variable output, with or without a receiver and/or refrigerant dryer. This allows you to have the optimum solution for your application.

OIL-FREE SYSTEM

The K series does not use an oil-lubricated crosshead drive. It is therefore ideally suited to sensitive applications where absolutely oil free compressed air is paramount such as in the pharmaceutical and food industries.

EFFICIENCY

As an oil-free compressor, the requirement for downstream air treatment is significantly reduced – if not eliminated with the K series. Therefore pressure losses experienced during the treatment process can be minimised or eradicated leading to a noticeable reduction in energy costs.

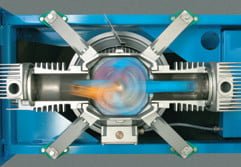

PUSH ROD PRINCIPLE

BOGE developed the K series oil-free piston compressor utilising state-of-the-art compressor technology. The cylinder is mounted horizontally, and a centrally located crankshaft operates a push rod principle, ensuring the piston remains parallel in the cylinder. This innovation vastly reduces cylinder ring wear experienced in all conventional systems.

FOCUS CONTROL 2.0

The K series is optionally available with the BOGE base or focus control 2.0. The focus control 2.0 ensures a continuous monitoring for pre- and maximum pressure and comes along with several functions and interfaces i.e. RFID, USB and ethernet.