Ideal Makina provides on-site production to its customers with its reliable, economical, long-life HYDROGEN GENERATOR. Instead of meeting your hydrogen needs with high costs vy purchasing cylinders, you can supply your own hydrogen generator and provide production at your business with much more affordable costs and can add value to your business by a pay back period of 1-2 years.

Which technology is the most proper one for my business?

Ideal Makina offers two different hydrogen production system to its customers by considering the hydrogen utilization capacity and auxiliary operating possibilities. While hydrogen generators producing with electrolysis method are suitable for needs in the range of 0-100 m3/h, natural gas sourced SMR HYRDOGEN GENERATORS are recommended for capacity needs over 100 m3/h.

- 1-320 Nm3/h. Hydrogen Gas Production Capacity

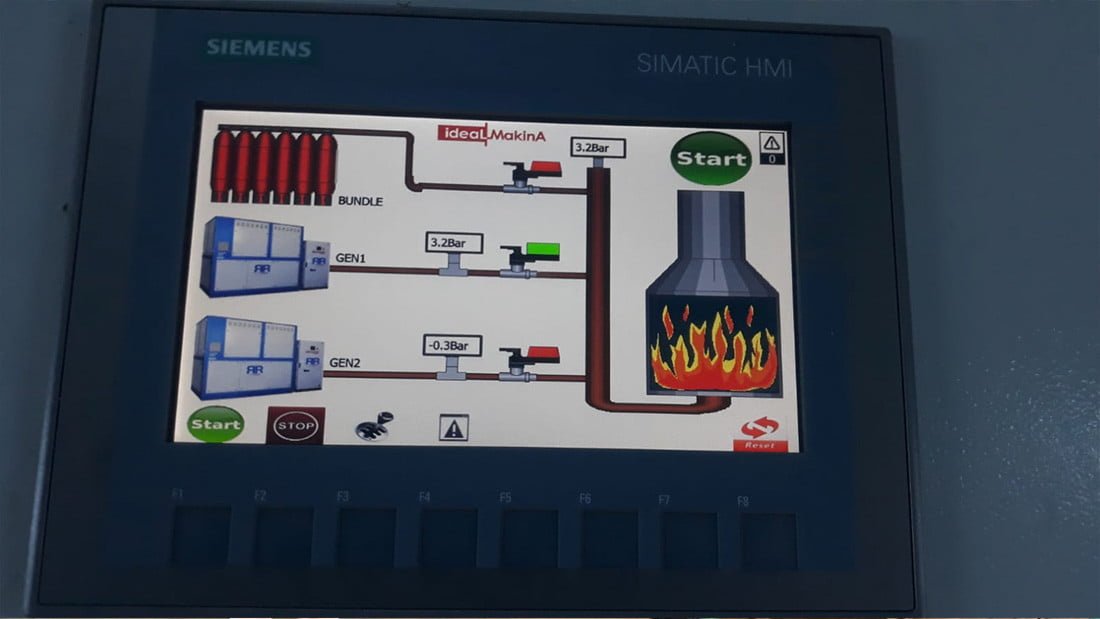

- Transformer, Control Unit, Hydrogen Generator and Purifier work in harmony without affecting each other negatively in seperate cabins.

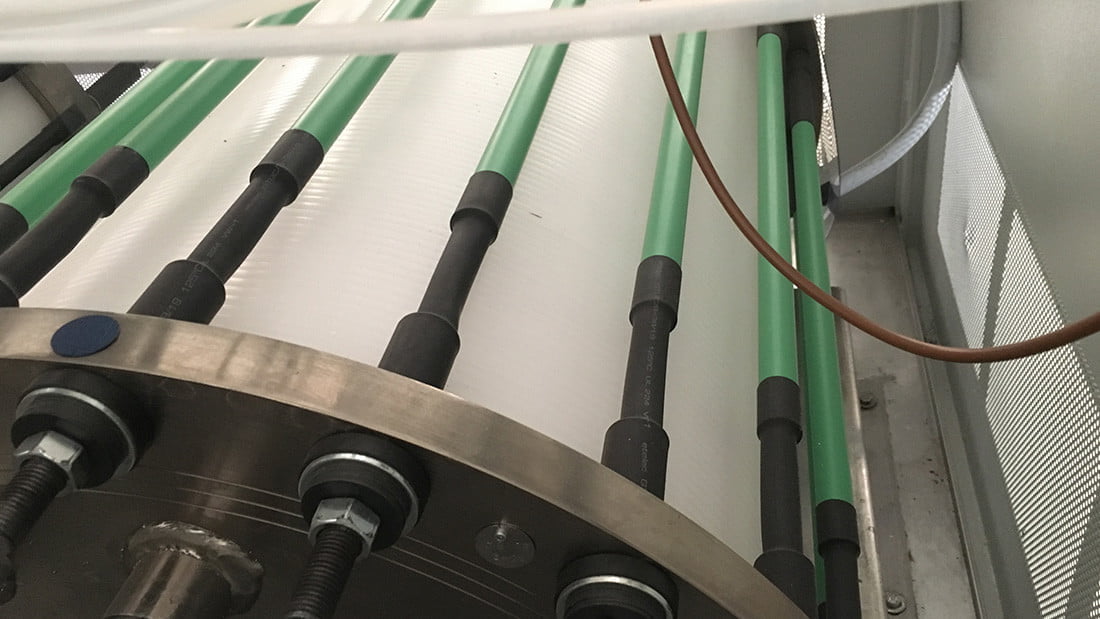

- Patented Special Hydrogen Purifying Towers

- High Efficiency, Long Life Bipolars Electrolitic Cells

- Standart Outlet Pressure at 5 bar

- Hydrogen Cylinder Filling Pressure at 150 bar

- Telemechanic M340 PLC Control

- Purity Guarantee with Hydrogen Purity Sensor and Analyser

- Cooling of an Electric Alternator in Power Plants

- In Heat Treatment Furnaces

- Pipe, Tube and Cable Factories

- Galvanized Material Annealing

- Flat Glass Factories

- Argon Purification in Air Seperation Plants

- Heating, Coating and Soldering Applications

- Jewelery Industry

- Continuous, 7/24 Hydrogen Production

- Economic production costs, cost savings up to %80

- Advanced Technology

- Reliable

- Easy Usage

- Full Automatic Operation

- Hydrogen Purity Up To %99,999

- 1-300 bar usage pressure

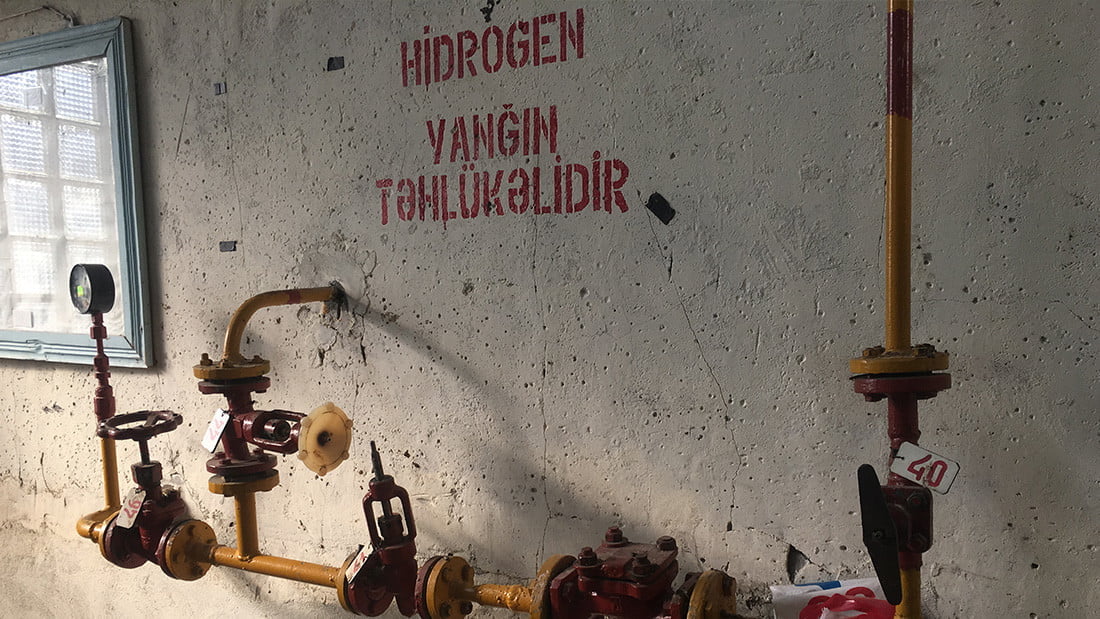

- 2006/42/EC Machinery Regulation

- 2014/30/EC EMC Regulation

- 2014/35/EC Low Voltage Regulation

- 2014/29/EC Simple Pressure Vessels Regulation

- 2014/68/EC PED Regulation

- EN 60204-1 Machinery Electrical Equipment Safety Regulation

- EN 60079-10 Hazardous Site Classification