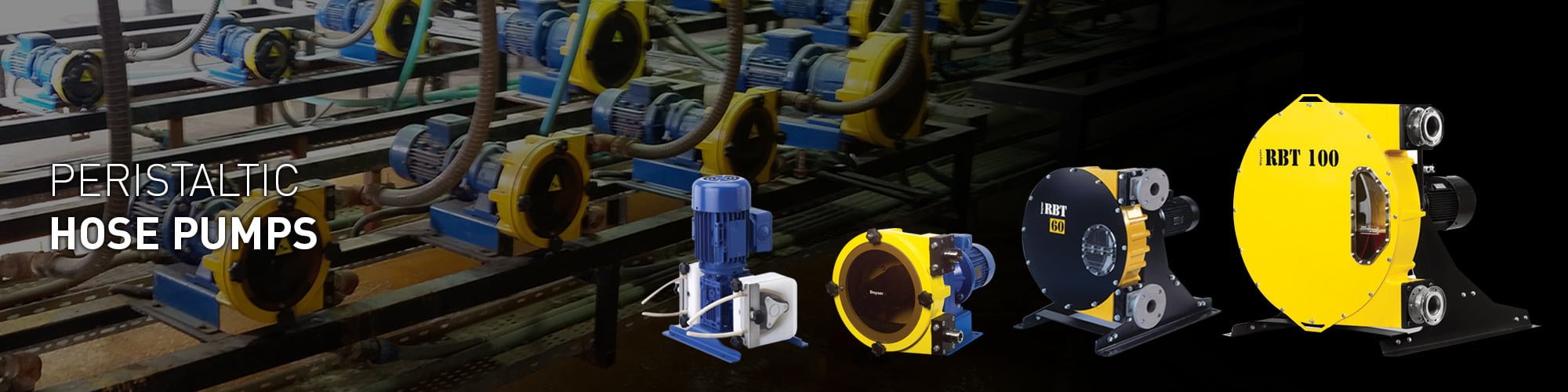

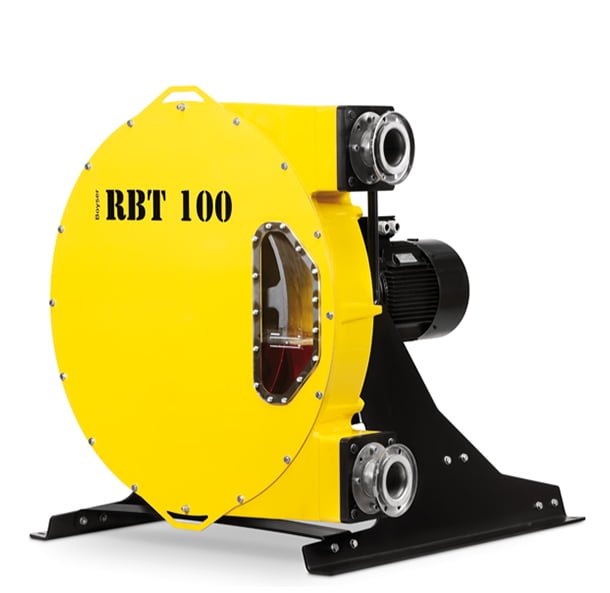

Hose pumps, also known as peristaltic pumps, are suitable for the transfer of corrosive chemicals, as well as for the transfer of solid particulate liquids and high viscosity fluids. The conveying liquids are contact with the just hose and connections – fittings. The pump and hose are determined according to the conveying liquid.

Pumps can run as dry and direction of rotation can be changed. When the hose pipe turn to its old form after compression, it causes an exact vacuum ability. Thus, very viscous liquids can be transferred without any problem by using Boyser peristaltic hose pumps.

Pump body is half-filled by specially manufactured oil to extend service period of hose, cooling the pump and lubricate with oil.Hose pumps have advantages for being only contacted with fluids instead rotating parts, are also protected at corroding conditions.

TECHNICAL FEATURES:

- Transfer of low and high viscosity fluids (Max. 100.000 cps)

- 0 – 60 m3 / h capacity range

- Max. suction head 9 mSS

- Dry running

- Dosing ability

- Changeable direction of rotation

- Easy and economical maintenance

- High abrasion and corrosion resistance

- Without sealing design

- Dry running feature

- Easy to clean

- Rich usage area under favour of different hose diameters and materials

- Hose Materials; NBR, NR, EPDM, NORPRENE, HYPALON

- Compatible for Ex proof – ATEX motor

MAIN AREAS :

- Mining

- Food and Beverage

- Pulp and Paper

- Ceramic

- Chemical

- Pharmaceutical

- Agriculture