max. 250 m3/h flow rate, max. 24 bar pressure

- Transfer of products containing solid particles (max. 150 mm)

- Transfer of low and high viscosity fluids (max. 4,000,000 mPas)

- Ability to pump fluids with four different stator and rotor geometries with max. 250 m3/h flow rate, max. 24 bar pressure

- Ability to work with abrasive, corrosive, sticky, crushing and foaming sensitive fluids

- Ability to pump fluids between -20°C and 300°C

- Providing smooth and linear, fluctuation-free, measurable flow

- Materials made of cast iron, SS 316L and other special alloys, SBBBPF, NBR Viton, PFTA, etc.

- FDA-approved elastomer options

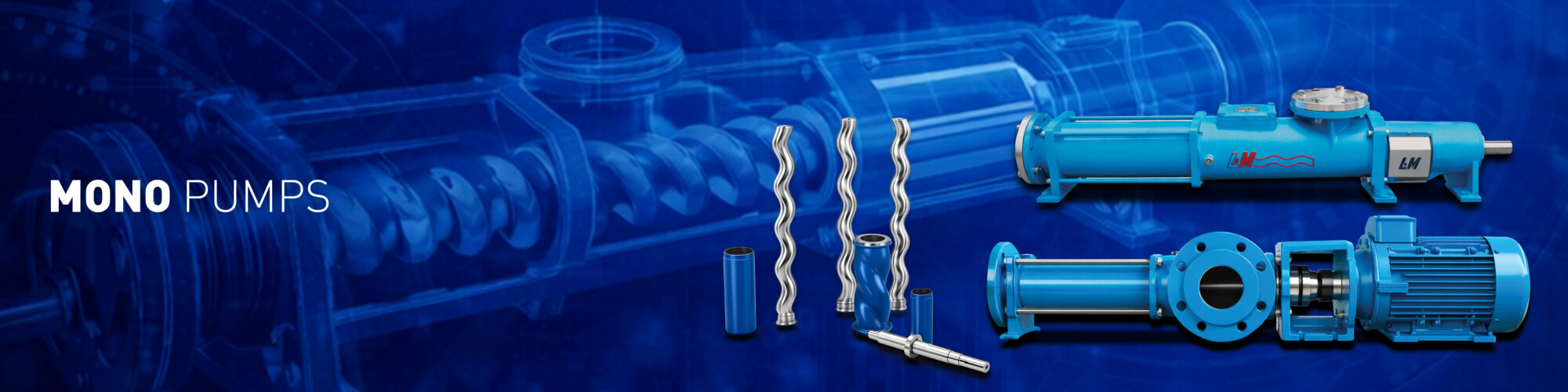

- Rotor: Stainless Steel (304-316L-316Ti) – Tool Steel – C45 (alternative chrome plating)

- Stator: NBR – NBRL – EPDM – Viton – PTFE – Silicone

- Suitable for CIP/SIP applications

- Dry running and overpressure protection

- Trouble-free operation for many years with readily available and economical spare parts

- Very easy maintenance thanks to quick rotor and stator assembly and disassembly

- High efficiency in the pump due to very short maintenance times

- Low spare part cost for rotor and stator

- Less space required for maintenance