Use 18 Barg Ideal Air Dry Air for Laser Cutting, Forget Your Cutting Gas Costs!

Various gases are used for laser cutting by laser machines These gases are purchased with cylinders for which high amounts are paid.

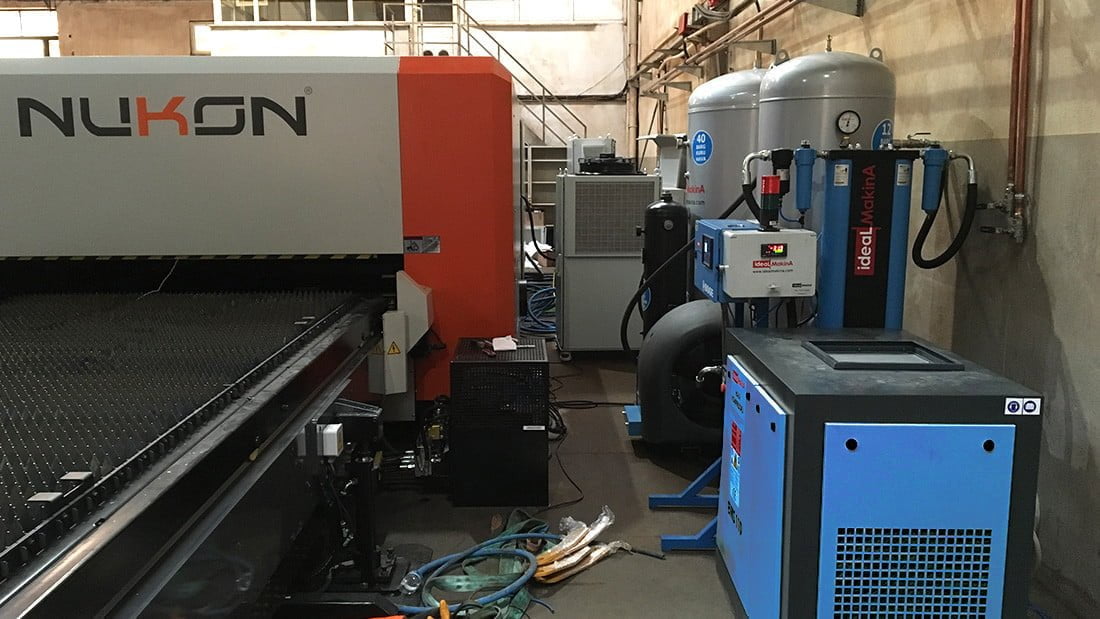

With Ideal Air Dry Air Generators designed by İdeal Makina, 18 barg air is being produced according to ISO standards and is used as direct cutting air. With the help of high pressure air, the process of “purchasing cylinder with the old system” is becoming an end.

The costs of monthly cylinder purchasings will become an end with Ideal Air Dry Air Generators. As there are no additional transportation costs, cylinder transportation labor also ends. The danger brought by high – pressure cylinders will also be eliminated additionally.

The quality range produced at 18 bar with Ideal Air Dry Air Generators is according to the standarts of ISO 8573-1 Class 1.2.1.

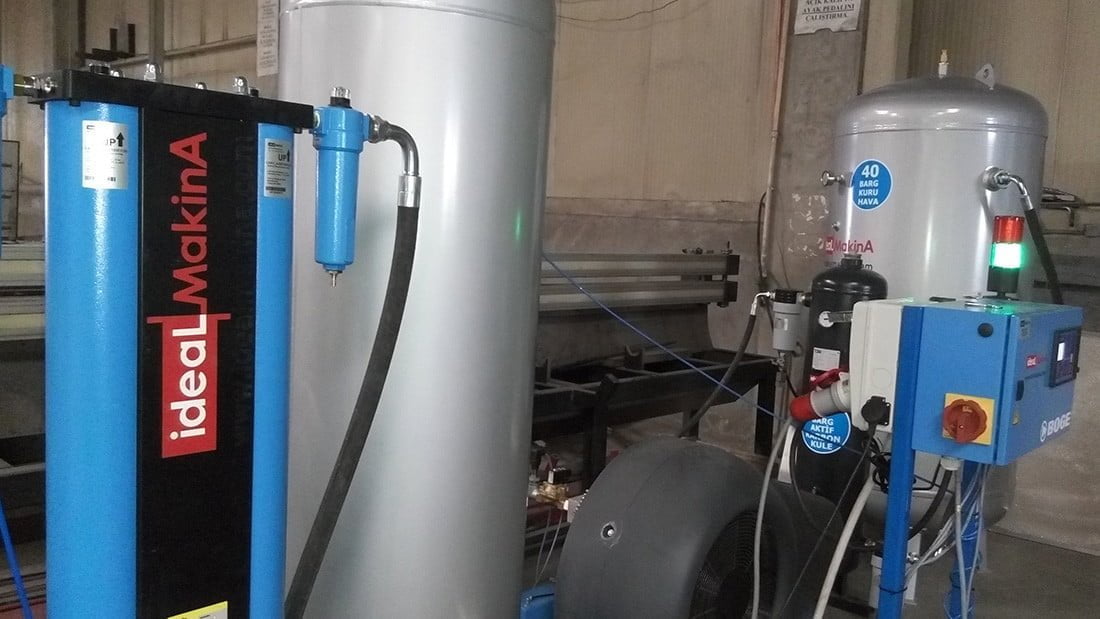

Unlike conventional 25-40 Barg oil-injected boosters, oil-free booster compressors are used in IdealAir Dry Air Generator Systems. Thus, problems such as heated lens-glass and fiber cable combustion caused by oil, water and particles in compressed air produced with oil-injected boosters are prevented and malfunctions that are not covered by the warranty are eliminated.

Through the Dew Control Control Panel integrated into the system, oil-free and dryness can be guaranteed in the cutting air coming to the laser head. The Active Carbon Tower and Desicant Dryer used in the system provides dry and oil-free air flow by continuously measuring with analyzers. The system automatically shuts down against possible dewpoint (water-humidity) problems in the compressed air system. Air flow to the laser machine is also being stopped, the audible and visual warning system gets activated and warns the operator. Thus, damage to the laser machine is prevented.

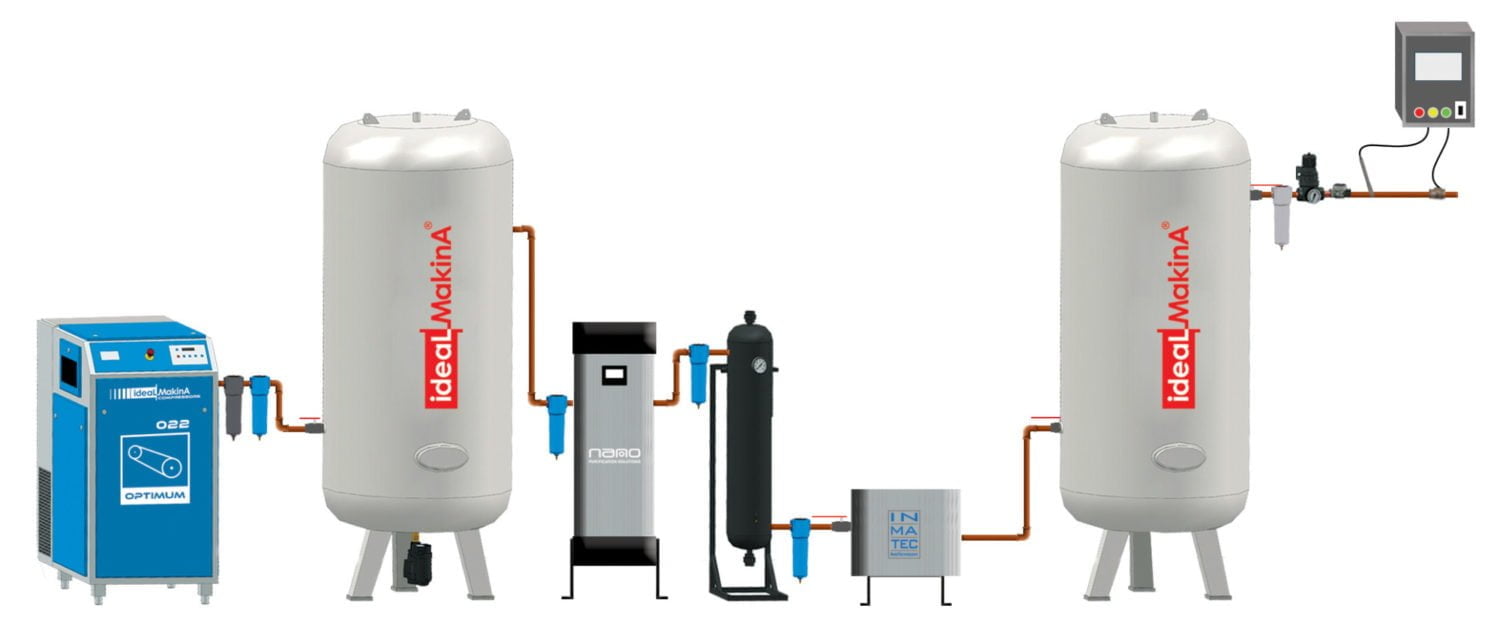

WORKING PRINCIPLE:

Atmosphere air is sucked through a compressor and pressurized to 7 or 10 Barg range. Compressed air is stored in the air tank by applying the equipment suitable for its capacity over drying and filtration processes. Stored air is increased up to 18 Barg with an high pressure booster compressor. 18 Barg compressed air is stored in tanks for the last time by filtering with special 18 Barg pressure resistant conditioners. By adjusting the desired cutting pressure; the air is ready to be used.

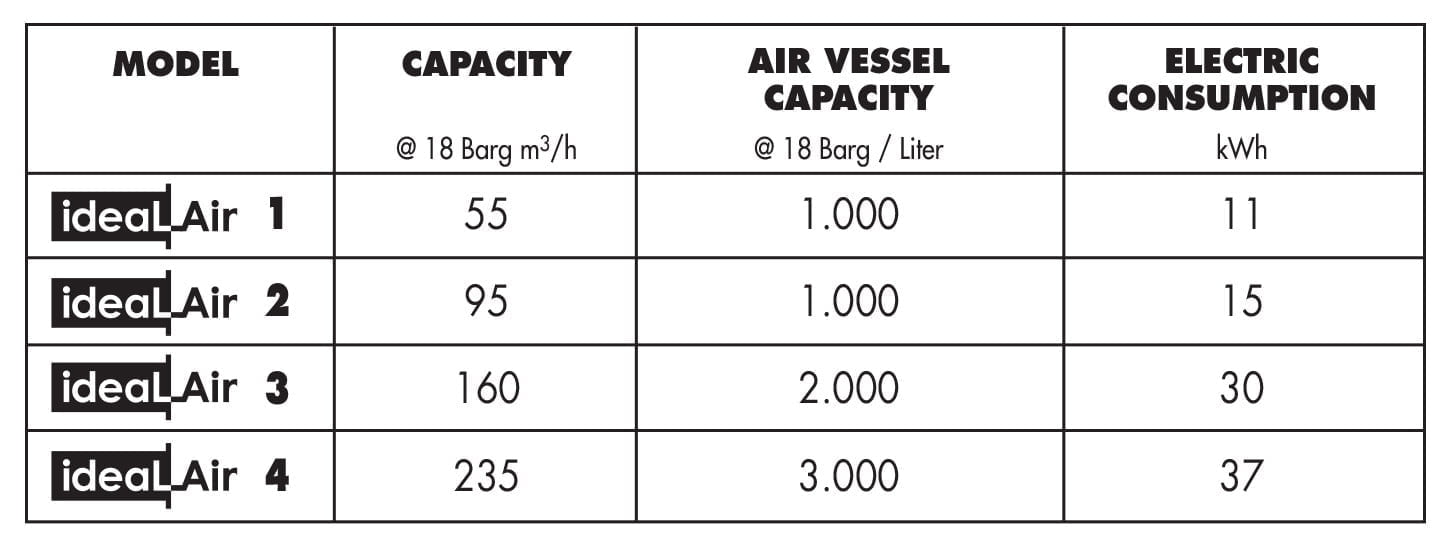

IDEAL AIR 55 – IDEAL AIR 95 – IDEAL AIR 160 – IDEAL AIR 235

- More economical cutting opportunity with 18 Bar dry air

- Dry air at ISO 8573-1 Class 1.2.1 standarts.

- – 40°C Dew Point

- Max. 0,003 mg/m3 Oil Content

- Max. 0.01 ppm particul

- Design suitable for working 7/24

- Fully Equipped Safety System

- Provides high amount of dry air reserves

- 2 – 4 times faster cutting compared to oxygen cutting