Avantajları:

- %99,5 Ultra High Purity Oxygen

- Guaranteed Purity: Continious O2 Analysis

- Full Safety

- Proven Savings

- No more logistic constraints

- END On External Oxygen Supply Problems!

- Fully Automatic Operation

- Eco-friendly solutions: Zero Delivery & Zero Emmission Of Pollutants

DESIGNED FOR?

Aviation, Aircraft

Used for filling of oxygen cylinders that will provide the necessary oxygen to the passengers due to the pressure drop in the cabin in case of an emergency.

Medical

Used in hospitals, laboratories, institutes, universities where high purity is required.

Oxygen Cutting

With this process, pure oxygen is used to allow the metal to reach the melting point. Suitable for thick and hard metal cutting. (> 4mm)

Brazing, Welding

High purity oxygen is used instead of air in increasing the degree of burning. Herewith, local melting occurs in the metal part in the process.

Laser Cutting

To perform a smooth cut, high purity and pressure are required. High purity makes it easier to paint the cut metal.

Plasma Cutting

High purity oxygen is used for faster and smoother cutting of high thickness black sheet on CNC-Plasma and Oxy-fuel CNC cutting machines.

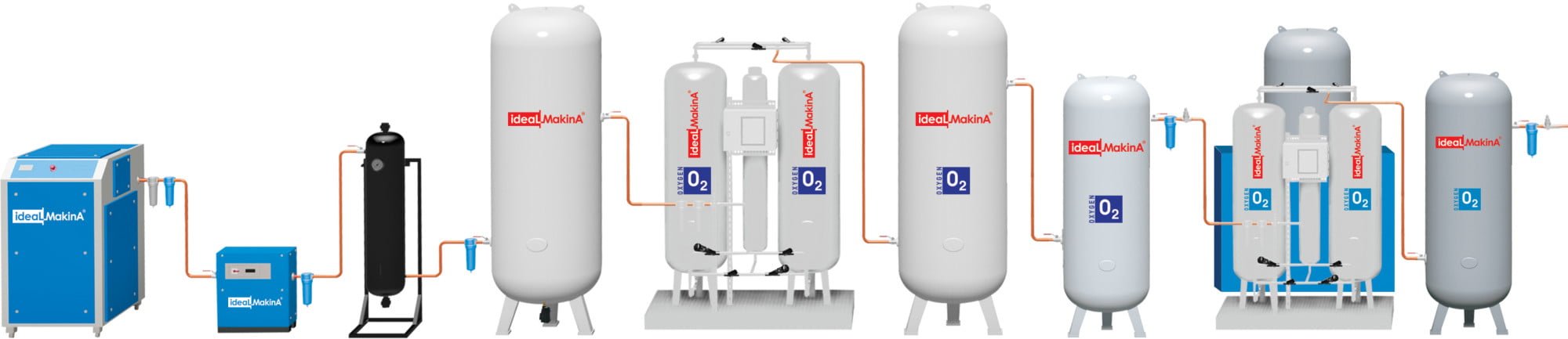

AVAILABLE INSTALLATION OPTIONS

Stand Alone System

Ideal Makina Oxygen Generators use PSA (Pressure Swing Adsorption) technology to produce oxygen gas from the air.

Ideal Makina Oxygen Generators consist of two tanks containing ZEOLITE. The air; which is pressurized by passing through the air conditioning equipments, enters from the bottom side of the first tank and passes through the entire ZEOLITE inside the tank and transmits it to the oxygen stock tank in high purity.Meanwhile nitrogen, argon, carbon monoxide and other gases trapped by ZEOLITE are released to the atmosphere through exhaust. After the operation of the first tank is completed within the time interval set by the touch control panel, conditioned air enters the bottom of the second tank and passes through the ZEOLITE and is being sent to the oxygen storage tank in pure form. Thus, continues oxygen gas production is achieved by tandem (synchronous) operation of two tanks filled with ZEOLITE.

SIMPLE and EASY CONTROL!

IDEAL MAKINA OXYGEN PRODUCTION SYSTEMS allow the generator to operate fully automatically with its “Touch Control Panel”. Through its user-friendly design and ergonomic touch control panel, you can instantly view precise measurements in all applications and can safe this data.

The user will be warned with the alarm that will appear on the screen through the sensors that detect deviations other than the desired parameters.

In addition, the Mobile Application provides remote access to your generator with Industry 4.0 technology from any point in the World.