NANO heatless, chemical air dryers are produced in the UK and are in modular design in terms of easy assembly and footprint. However, the snowstorm filling technique guarantees intensive filling and maximum surface contact, eliminating the risk of dusting. In addition, the special design in which cylindrical volumes produced by aluminum extrusion are combined with manifolds. It does not require hydrostatic pressure testing, but it also gives confidence in terms of work and operator health safety.

HOW DOES IT WORK?

This type of dryer used in the compressor line has adsorption material filled in two separate aluminum extruded chambers. While the compressed air passes through one of these chambers, the water vapor inside is being captured and dried by the adsorbent. As soon as the adsorption material contained in this chamber will be saturated after a while, while the other chamber begins the drying process, the saturated chamber enters the regeneration process and the system operates as a tandem. In principle, up to 13-18% air loss occurs during regeneration. With the dew point analyzer of the Energy Saving System, adsorption and regeneration times are changed according to the desired air outlet quality, resulting in much less air loss and less electricity consumption.

APPLICATION FIELDS

On pneumatic equipment in the instrument air line, paint shops, at points in contact with the product in the food industry or at risk of contact, pharmaceutical industry, laser cutting makinalarında, ozone generator air supply, medical breathing.

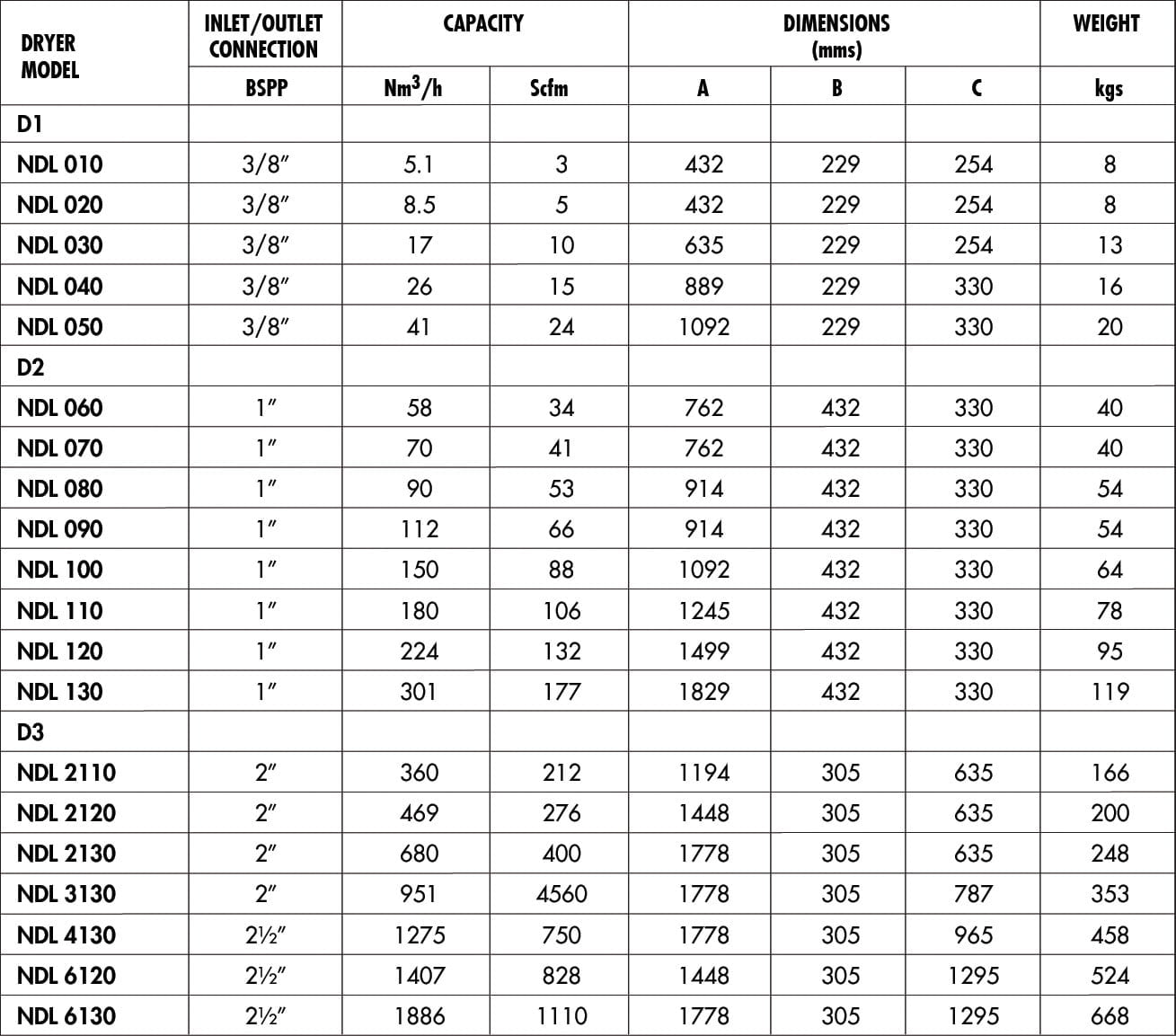

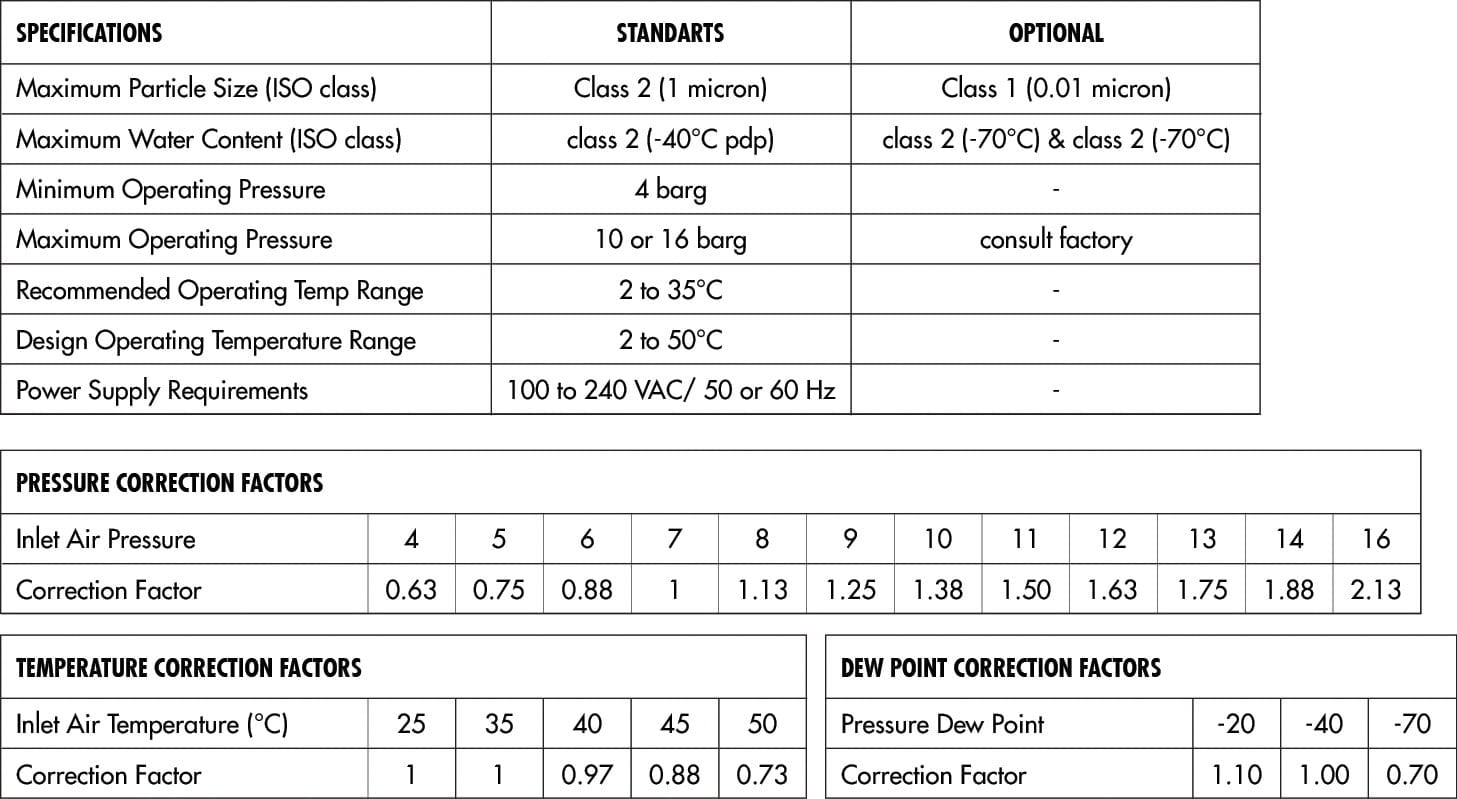

D1 | D2 | D3 SERIES

- Flow Range: 5 – 1.886 Nm3/h

- Air Outlet Dew Point: -20°C, – 40°C, -70°C options

- Maximum Running Pressure: 16 barg

- Minimum Running Pressure: 4 barg

- Maximum Air Inlet Temperature: 50°C

- ORIGIN: ENGLAND

- Energy Saving Technology: Dewpoint Analyser

- Constant reliable dew point through constant flow and pressure inside the column

- Digital Control Panel

- Remote start / stop automatic operation depending on the compressor pressure

- Easy-to-change adsorbent cartridges in aluminum sleeves

- Integrated filter in air outlet adsorbent cartridge